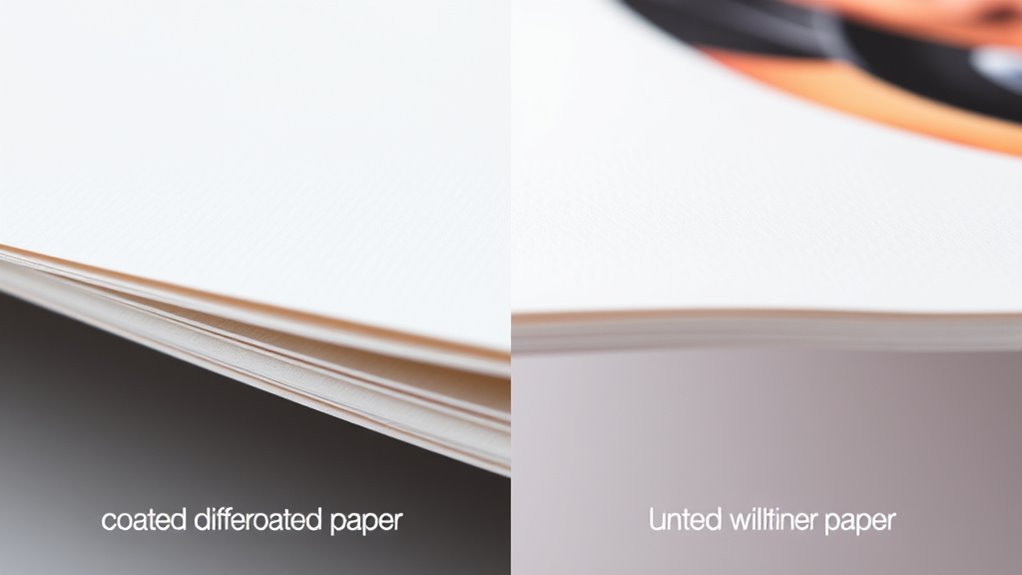

When choosing between coated and uncoated paper, you’ll notice coated paper delivers vibrant colors, sharp details, and a polished finish thanks to its smooth, glossy surface that minimizes ink absorption. In contrast, uncoated paper has a matte, textured feel that absorbs ink more, producing softer images and muted tones. Your choice impacts print clarity, durability, and overall look. To discover how these differences affect your projects, explore further for detailed insights.

Key Takeaways

- Coated paper produces sharper images with vibrant colors due to its smooth, glossy surface that limits ink absorption.

- Uncoated paper absorbs more ink, resulting in softer, muted colors and less defined details in print results.

- Coated surfaces enhance contrast and clarity, making fine details more crisp and precise.

- Uncoated paper offers a matte finish, producing softer images with reduced glare but less sharpness.

- Print longevity and durability are generally better on coated paper due to its resistance to scratches, moisture, and fading.

Epson Premium Presentation Paper MATTE (8.5×11 Inches, Double-sided, 50 Sheets) (S041568),Bright White

Perfect for non-glare photographs, craft projects and signage.

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Surface Texture and Finish

When choosing between coated and uncoated paper, surface texture and finish play a crucial role in how your print projects look and feel. Coated paper often offers a smooth, glossy surface, ideal for vibrant images and sharp details. An embossed finish can add a tactile element, giving your print a sophisticated touch. In contrast, uncoated paper typically features a matte surface, providing a softer, more natural feel that’s easier to write on. This matte surface reduces glare and enhances readability, making it perfect for text-heavy materials. Your choice depends on the desired look and feel; coated papers deliver a polished, shiny finish, while uncoated papers offer a more subdued, textured experience. Both options influence how recipients perceive your work, so select the surface texture that aligns with your project’s purpose. Additionally, understanding how automation and innovation impact printing processes can help you choose the most efficient and effective paper type for large-scale productions. Incorporating advanced coating techniques can further enhance surface qualities and print results, especially in high-volume printing. Moreover, selecting the appropriate surface can also affect color accuracy, ensuring your images appear vibrant and true to life. Staying informed about emerging digital printing technologies can help optimize your selections for better quality and efficiency.

HP HeavyWeight Project Paper, Matte, 8.5×11 in, 40 lb, 250 sheets, works with inkjet, PageWide, laser printers (Z4R14A)

Get consistent, cost-effective results with a matte finish

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Absorption and Ink Holdout

Have you ever noticed how some prints look vibrant and crisp while others appear dull or blurry? That’s often due to absorption and ink holdout, which are directly influenced by coating application. Coated paper has a smooth surface that limits ink penetration, keeping ink on the surface for sharper details and richer color. Uncoated paper, with its rougher texture, absorbs more ink, which can cause colors to appear muted and details less defined. When you choose coated paper, you’re ensuring better ink holdout, resulting in cleaner, more precise images. Additionally, paper porosity plays a crucial role in how ink interacts with the paper surface, affecting both absorption and image quality. The surface smoothness of coated paper minimizes ink bleed, further enhancing print clarity. Furthermore, ink absorption impacts not only the sharpness but also the drying time and durability of the print, making it an important factor to consider. A comprehensive understanding of coating materials can help optimize print results for specific needs. Conversely, uncoated paper’s higher absorption can lead to bleeding and less crispness. Understanding how coating affects ink penetration helps you select the right paper for your print job, achieving the desired clarity and vibrancy.

CanonInk Glossy Photo Paper 8.5" x 11" 100 Sheets (1433C004)

This vibrant, glossy photo paper gives you crisp, clear photos that are High quality without the High cost…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Color Vibrancy and Brightness

Coated paper enhances color vibrancy and brightness by providing a smooth, reflective surface that amplifies the appearance of printed images. With a glossy finish, colors appear more vivid and striking, making photos pop and designs stand out. Conversely, a matte surface offers a softer, muted look, reducing glare and giving colors a subtle, understated appeal. The choice between these finishes impacts how your colors are perceived and how bright your prints look. To compare, consider the following table:

| Feature | Glossy Finish | Matte Surface |

|---|---|---|

| Reflectivity | High, boosts brightness | Low, reduces glare |

| Color Vividness | Enhanced, vibrant | Softer, subdued |

| Ideal Use | Photos, vibrant graphics | Fine art, elegant designs |

Your selection influences the overall brightness and color impact of your print. Additionally, understanding print quality factors can help you choose the best finish for your project. For example, the coating process can also affect how well the colors are preserved and displayed in your final print. Being aware of print durability can further guide your choice based on how long you want your print to maintain its vibrancy and brightness. Moreover, selecting the appropriate paper finish can also influence the color retention over time, especially in varying lighting conditions.

printing paper for color accuracy

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Sharpness and Detail Reproduction

Ever wondered how paper surface affects the sharpness and detail of your prints? Your choice between coated and uncoated paper impacts the clarity of fine lines and intricate details. Coated paper offers smoother textures with minimal texture variations, resulting in sharper images and crisper text. Its glossy differences enhance the contrast, making details stand out more vividly. Uncoated paper, with its rougher surface and visible texture variations, can cause slight blurring or softer edges, especially in detailed images. This roughness diffuses ink slightly, reducing overall sharpness. If you need precise detail and clean lines, coated paper is your best bet. Additionally, the materials used in coated papers often contribute to their ability to produce vibrant and accurate print results, which is an important aspect of print quality. Understanding the surface texture of different papers can help you select the right type for your project. Furthermore, the manufacturing process of coated papers often results in a more uniform surface that enhances print clarity.

Durability and Longevity

When it comes to durability and longevity, the type of paper you choose can considerably influence how well your prints withstand time and handling. Coated paper generally offers superior coating durability, protecting prints from scratches, moisture, and fading. It resists aging better, maintaining vibrant visuals over time. Uncoated paper, however, tends to age faster, with inks more prone to smudging and fading as the paper deteriorates. Your choice impacts not just appearance but how long your prints remain intact. Use this comparison to guide your decision:

| Aspect | Coated Paper | Uncoated Paper |

|---|---|---|

| Coating durability | High, resists wear and tear | Lower, more susceptible to damage |

| Aging | Slower, maintains quality longer | Faster, shows signs of aging sooner |

Cost and Budget Considerations

Cost is a key factor when choosing between coated and uncoated paper, as it can substantially impact your overall budget. You’ll want to explore different pricing options to find the best fit for your project’s needs. Coated papers often come with higher costs due to their specialized finishes, which can strain tight budget constraints. Uncoated papers tend to be more affordable, making them suitable for large-volume printing or projects with limited funds. Consider not just the initial price but also the long-term costs, such as printing quality and durability, which can influence your overall expenses. Additionally, understanding the types of paper finishes can help you select the most cost-effective option that meets your quality requirements. By evaluating your budget constraints and comparing pricing options carefully, you can make an informed decision that balances quality with cost-effectiveness. A further consideration is the printing process, as some finishes require specific equipment or techniques that could add to the overall cost. Moreover, print quality can significantly impact the perceived value of your printed materials, influencing your choice between coated and uncoated options. For example, the choice of paper surface can also affect how color accuracy appears in your final print, which is an important aspect of print results.

Common Uses and Applications

You’ll find coated paper often used for promotional materials and high-quality printing because it makes colors pop. Uncoated paper is popular for business documents and fine art printing, offering a more textured, professional look. Understanding these applications helps you choose the right paper for your specific needs. Additionally, inspirational quotes about fatherhood can serve as a reminder of the importance of support and guidance in all aspects of life.

Promotional Materials

Promotional materials are essential tools for businesses looking to attract attention and communicate their message effectively. When choosing paper, consider how embossed finishes can add a touch of elegance and make your materials stand out. These textured effects create tactile sensations that engage the senses and leave a lasting impression. Coated paper often enhances these effects, making embossed details sharper and more vibrant, which is perfect for brochures, catalogs, and business cards. Uncoated paper, on the other hand, offers a more natural feel, suitable for stationery and promotional items where a softer touch is preferred. Both options can be customized to suit your branding needs, but understanding how embossed finishes influence tactile sensations will help you select the best paper for your promotional campaigns.

Fine Art Printing

Fine art printing is widely used to reproduce paintings, photographs, and other artistic works with exceptional detail and color accuracy. Your choice of paper influences the final look, offering texture variation and various finish options. Coated papers provide smooth, glossy surfaces that enhance vibrant colors and sharp details, ideal for photo reproductions. Uncoated papers offer a matte or textured finish, adding depth and a tactile quality to artwork. Consider these options:

| Texture/Finish | Description | Best Use |

|---|---|---|

| Glossy | Smooth, reflective surface | Bright, colorful images |

| Matte | Non-reflective, muted tones | Fine art pieces needing subtlety |

| Textured | Visible surface pattern | Artistic works emphasizing tactile feel |

Your selection will shape the artwork’s visual impact and presentation.

Business Documents

Business documents serve as essential tools for communication, record-keeping, and professional presentation across various industries. When choosing paper for reports, proposals, or official correspondence, consider lamination options to enhance durability and appearance. Coated paper often offers a smoother finish, making it ideal for professional printing, while uncoated paper provides a more natural feel. The coating thickness influences the document’s look and feel; a thicker coating can improve image sharpness and gloss, giving a polished look. For important business materials, selecting the right combination of lamination options and coating thickness guarantees your documents are both visually appealing and resilient. This careful choice can leave a lasting impression on clients and partners, reinforcing your professionalism and attention to detail.

Environmental Impact and Sustainability

When choosing between coated and uncoated paper, you should consider their recycling potential and reusability. The chemical use during production and the overall carbon footprint also play significant roles in their environmental impact. Understanding these factors helps you make more sustainable choices for your printing needs.

Recycling and Reusability

Have you ever considered how coated and uncoated papers differ in their recyclability and environmental impact? Coated paper generally has lower recycling efficiency because the coatings can interfere with the paper recycling process, making it harder to separate fibers and contaminants. This reduces reusability potential, meaning coated paper often ends up in landfills or is downcycled into lower-quality products. Uncoated paper, on the other hand, tends to be more recyclable because it lacks the complex coatings that hinder recycling efforts. Its fibers are easier to process, supporting better reusability and sustainability. If eco-friendliness is a priority, choosing uncoated paper can make a significant difference, as it promotes more efficient recycling and has a smaller environmental footprint overall.

Chemical Use in Production

While uncoated paper generally supports better recycling, its production often involves the use of chemicals that can impact the environment. The chemical composition used during the production process influences sustainability and environmental health. Manufacturing uncoated paper typically requires chemicals like sizing agents, bleaching agents, and fillers, which may release pollutants. These chemicals can leach into ecosystems if not managed properly. Additionally, the choice of chemicals affects the recyclability and biodegradability of the paper. The production process might also involve hazardous substances to enhance paper qualities, raising concerns about environmental safety. To minimize impact, manufacturers are shifting toward eco-friendly alternatives and reducing chemical usage. Being aware of these factors helps you choose more sustainable options and encourages environmentally conscious production practices.

- Chemical additives used in sizing and coating

- Bleaching agents and their environmental effects

- Use of fillers and pigments in paper manufacturing

- Alternatives to hazardous chemicals

- Impact of chemical residues on recyclability

Carbon Footprint Impact

The carbon footprint of coated versus uncoated paper substantially influences their overall environmental impact and sustainability. Coated paper often requires more energy during production due to eco friendly coatings, increasing its carbon emissions. Conversely, uncoated paper generally has a lower footprint but may be less durable, affecting recyclability factors. The table below compares their environmental aspects:

| Aspect | Coated Paper | Uncoated Paper |

|---|---|---|

| Production energy | Higher due to coatings | Lower |

| Recyclability factors | Slightly reduced by coatings | Easier to recycle |

| Eco friendly coatings | May contain less biodegradable components | Usually absent |

| Carbon emissions | Higher due to processing | Lower |

| Sustainability | Less sustainable long-term | More sustainable |

Choosing uncoated paper can reduce your environmental footprint, especially when paired with recyclability practices.

Frequently Asked Questions

How Does Coating Affect the Paper’S Recyclability?

When you consider how coating affects paper’s recyclability, it’s important to realize that coatings can influence the recycling impact and eco friendliness. Coated paper often contains plastics or other materials that make recycling more challenging, potentially reducing its eco friendliness. You might find that uncoated paper is easier to recycle and more environmentally friendly, making it a better choice if sustainability is your priority.

Can Uncoated Paper Be Coated After Printing?

You can apply post-printing coating to uncoated paper, but it’s not always ideal. Residual coating might not adhere well if the paper isn’t prepared properly, leading to uneven results. It’s crucial to verify the surface is clean and smooth. Keep in mind, post-printing coating is typically used to enhance durability or appearance, but it may not achieve the same quality as pre-coated paper.

Which Paper Type Is Better for Outdoor Signage?

For outdoor signage, you should consider durability comparison and cost analysis. Coated paper offers better weather resistance, making it more durable against moisture and UV exposure, ensuring your signs last longer. While uncoated paper is cheaper, it isn’t ideal outdoors as it can quickly degrade. Choosing coated paper might cost more upfront, but it provides a better balance of durability and value over time for outdoor signage.

How Does Coating Influence Printing Speed and Setup?

Imagine you’re printing a batch of banners, and coating durability impacts your process. Coated paper allows faster printing setup because it has smoother surfaces, reducing ink absorption differences. This accelerates printing speed, especially for detailed images. With less ink absorption variation, you get consistent results, and setup times decrease. Coating simplifies printing, making it more efficient, especially when you need quick turnaround and sharp, durable prints.

Are There Health Risks Associated With Coated Paper Fumes?

You might wonder if coated paper fumes pose health risks. Generally, the fumes come from chemical exposure during manufacturing, not printing. Prolonged inhalation can affect your respiratory health, especially if you’re exposed to strong chemicals regularly. To minimize risks, guarantee proper ventilation and use protective equipment. While occasional exposure isn’t usually harmful, it’s smart to stay cautious about chemical fumes that could impact your respiratory health over time.

Conclusion

Choosing between coated and uncoated paper isn’t just a matter of preference—it’s about revealing the perfect print outcome. Will the glossy shine or natural texture elevate your project? The right choice can transform your results and even influence your budget. But what if the true difference lies beneath the surface? Dive deeper, explore your options, and discover the unexpected impact each type can have on your next print masterpiece. The decision awaits—are you ready to make it?