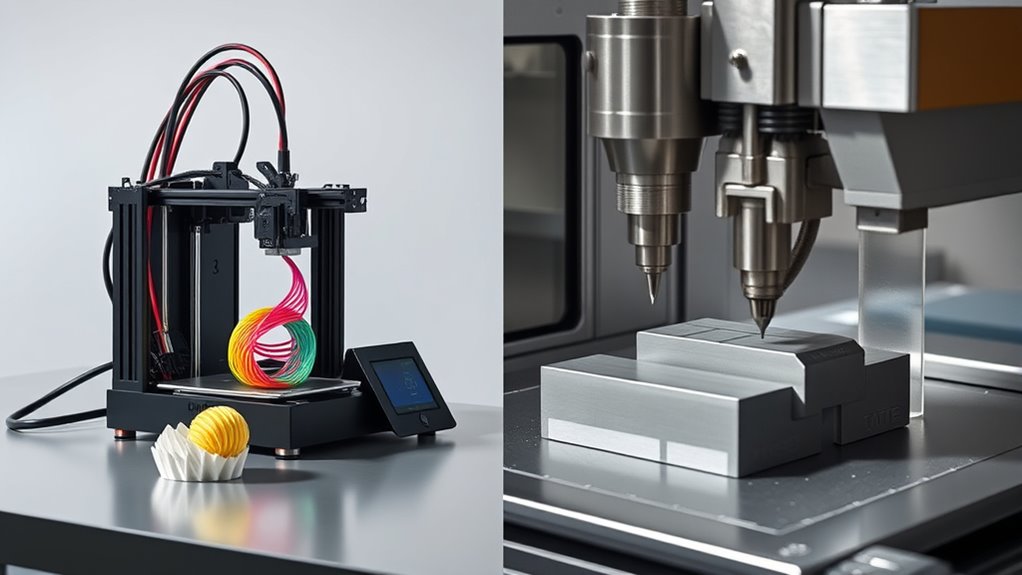

When choosing between 3D printing and CNC machining for prototyping, consider that 3D printing usually offers lower upfront costs, faster turnaround, and is ideal for complex geometries, while CNC provides better surface finish, durability, and access to a wider range of materials like metals. If you’re aiming for quick iterations or detailed visual prototypes, 3D printing is a strong choice. For final testing or demanding materials, CNC excels. Keep exploring to see how each method can fit your project.

Key Takeaways

- 3D printing offers rapid, low-cost prototyping with complex geometries, while CNC provides superior surface finish and material strength.

- 3D printing is more cost-effective for small volumes and quick iterations; CNC becomes economical for larger production runs.

- Material options are limited for 3D printing but broader with CNC, including metals like aluminum and steel.

- Surface quality and visual detail are generally better with CNC machining due to its precision finishing.

- Combining both methods can optimize prototyping speed, cost, and final product quality.

When choosing between 3D printing and CNC machining, understanding their differences is essential to selecting the right manufacturing method for your project. One of the first considerations is material selection. With 3D printing, you’re often limited to specific thermoplastics, resins, or powders, which work well for rapid prototyping but might not match the strength or durability of materials used in CNC machining. CNC, on the other hand, can handle a wider range of materials, including metals like aluminum, brass, and steel, as well as plastics such as acrylic and nylon. This flexibility is critical if your prototype needs to simulate the final product’s material properties or if you plan to test mechanical performance. Knowing the available material options helps you decide which process aligns best with your project’s functional requirements. Additionally, color accuracy can be a factor in certain prototypes where visual fidelity is important, and CNC machining often provides better surface finishes to support this. Cost analysis is another imperative factor. 3D printing generally offers lower upfront costs, especially for small runs or complex geometries, because it doesn’t require expensive tooling or molds. Its rapid turnaround can save you money if you need quick iterations during the design phase. However, as the volume increases, per-unit costs tend to rise, making it less economical compared to CNC machining, which has higher initial setup costs due to tooling but becomes more cost-effective for larger runs. CNC machining’s material costs can also vary depending on the material chosen; metals tend to be more expensive than plastics, influencing your overall budget. When you perform a cost analysis, consider not just the production expenses but also factors like lead time, material wastage, and post-processing needs. Sometimes, a hybrid approach—using 3D printing for initial prototypes and CNC for final testing or small production runs—can optimize both costs and project timelines.

Frequently Asked Questions

Which Method Offers Better Surface Finish Quality?

CNC machining generally offers better surface finish quality, providing superior surface smoothness and finish precision. You’ll notice fewer layer lines and a more refined, professional look compared to 3D printing. If your project demands a high-quality surface finish, CNC machining is the better choice. It’s ideal for prototypes requiring detailed, smooth surfaces, while 3D printing might need additional post-processing to achieve similar finish standards.

How Do Material Costs Compare Between 3D Printing and CNC Machining?

Think of material costs like a grocery bill—3D printing often costs less for small runs because of its material variety and cost scalability. You might pay a premium for high-quality or specialty filaments, but overall, 3D printing tends to be more budget-friendly for prototypes. CNC machining, however, can become more expensive as you increase volume, especially with pricier metals. So, your choice depends on your project’s scale and material needs.

What Are the Environmental Impacts of Each Process?

You should consider that 3D printing often has lower energy consumption and produces less waste, especially when you use recycling practices for leftover filament. CNC machining, on the other hand, can generate more material waste and consume more energy due to high-speed metal removal. Both processes impact the environment differently, but your choice depends on how you manage recycling and energy efficiency in your workflow.

Can Both Methods Produce Complex Geometries Reliably?

You can absolutely rely on both methods to produce complex geometries, and they do it with astonishing precision. With the right choice, you’ll unlock unparalleled design flexibility and scale production seamlessly. 3D printing excels in creating intricate, detailed structures, while CNC machining offers robust, high-precision results for more durable prototypes. Both methods are game-changers, ensuring your designs come to life exactly as you envision, no matter how complex.

How Do Lead Times Differ for Prototypes Using Each Technology?

Your lead times differ markedly between the two methods. 3D printing offers faster production speed because it requires minimal tooling, allowing you to produce prototypes quickly and with fewer setup steps. CNC machining, on the other hand, involves more tooling requirements and setup time, which can slow down your process. If speed is critical, 3D printing is generally the quicker option, but CNC can deliver higher precision for complex parts when needed.

Conclusion

So, which method suits your prototyping needs best—3D printing or CNC machining? Both have their strengths, but the choice ultimately depends on your project’s complexity, material requirements, and budget. Do you want rapid iteration and intricate details, or precision and durability? Consider your priorities carefully. Whichever you choose, understanding their differences guarantees you make an informed decision that propels your innovation forward. Ready to bring your ideas to life?