When choosing between digital and offset printing, consider your project’s size, quality needs, and turnaround time. Digital printing is ideal for small runs, quick delivery, and customization, while offset delivers superior color accuracy, sharp finishes, and better cost efficiency for large volumes. For high-quality, consistent results on big projects, offset is the better choice. If you want to understand more about which method suits your specific needs, explore further details ahead.

Key Takeaways

- Offset printing delivers superior color accuracy and high-quality finishes, ideal for large-volume, professional projects.

- Digital printing is more cost-effective for small runs and offers quick turnaround times with easy customization.

- Offset is better suited for high-volume jobs due to lower per-unit costs at scale, while digital excels in short runs.

- Digital printing provides flexible, on-demand options suitable for personalized or last-minute projects.

- For precise color matching and detailed print quality, offset printing generally outperforms digital methods.

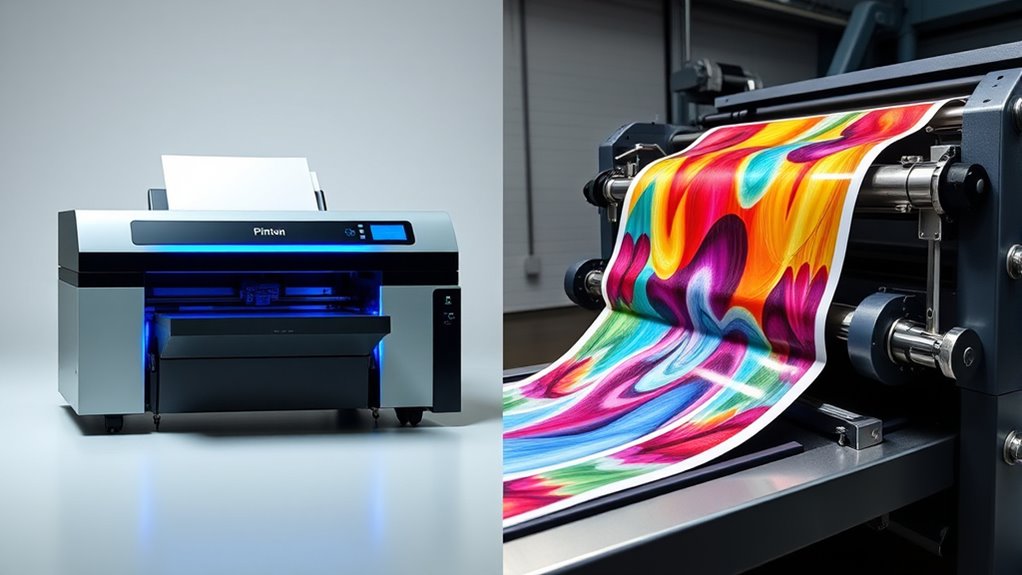

When choosing a printing method, understanding the key differences between digital and offset printing can help you make an informed decision. One of the main factors to weigh is print quality. Offset printing is known for delivering superior image clarity, sharpness, and color accuracy, especially for high-volume projects. It uses plates to transfer ink onto paper, which results in crisp lines and consistent color reproduction across large runs. If you need professional-grade output for brochures, catalogs, or fine art prints, offset printing often outperforms digital in terms of visual detail and overall finish. Conversely, digital printing has made notable strides in quality, and for smaller quantities or quick turnarounds, it can produce impressive results that meet most standards. Advances in digital technology now allow for vibrant colors and high-resolution images, making it a viable option for many applications.

Cost efficiency is another critical aspect. Digital printing tends to be more cost-effective for short runs or projects with a limited number of copies. Since it doesn’t require plates or extensive setup, you save both time and money upfront. Digital presses can start printing almost immediately, which is ideal for projects with tight deadlines or when you need to make last-minute changes. Offset printing, on the other hand, involves a more complex setup process, including creating plates and adjusting presses, which increases initial costs. While offset becomes more economical the larger the print run, it’s less cost-effective for small quantities. If you’re printing thousands of copies, offset’s per-unit cost drops considerably, giving you better value at scale. For smaller projects or when budget constraints are tight, digital printing offers a more affordable solution without sacrificing acceptable quality.

Another aspect to weigh is the flexibility and turnaround time. Digital printing offers greater flexibility because you can easily customize each piece, print on demand, and make quick adjustments without additional costs. This makes it perfect for personalized marketing materials or short-term campaigns. Offset printing requires more planning and setup, which means longer lead times but a higher quality output for large runs. If your priority is rapid delivery and customization, digital printing is the more suitable choice. However, if your focus is on consistent, high-quality output at a large scale, offset printing’s advantages become more apparent. Additionally, the color fidelity of offset printing often surpasses that of digital, making it more suitable for projects where precise color matching is essential.

Frequently Asked Questions

How Does Color Accuracy Compare Between Digital and Offset Printing?

You’ll find that offset printing generally offers better color accuracy because it provides superior color consistency and ink precision, making it ideal for projects demanding precise color matching. Digital printing, on the other hand, can sometimes have slight variations in color due to differences in inkjet or toner technology. If color accuracy is essential, offset printing usually delivers more consistent, vibrant results, while digital provides convenience with acceptable color fidelity.

What Are the Environmental Impacts of Each Printing Method?

You’ll find offset printing generally has a larger environmental footprint due to ink and paper waste, but it can use eco-friendly practices like soy-based inks and recycled materials. Digital printing is more eco-friendly overall because it produces less waste and consumes less energy. By choosing sustainable materials and eco-conscious practices, you can reduce environmental impacts with either method, making your printing more sustainable and responsible.

Can Digital Printing Handle Specialty Inks and Finishes?

Yes, digital printing can handle specialty ink options and finishing techniques. You can choose from metallic, neon, or textured inks to make your project stand out. Digital presses also support various finishing techniques like spot varnishes, embossing, and lamination, giving you creative flexibility. This makes digital printing ideal for customized, short-run projects that require unique finishes, ensuring your designs look professional and eye-catching.

How Do I Determine the Most Cost-Effective Option for Small Quantities?

To find the most cost-effective option for small quantities, consider digital printing, which often offers quicker print speeds and potential bulk discounts for multiple jobs. It minimizes setup costs, making it ideal for short runs. Offset printing, while economical for larger quantities, can be costly upfront. Weigh your needs carefully, balancing print speed, volume, and budget, to choose the method that best aligns with your project’s goals.

What Are the Maintenance Requirements for Digital Vs Offset Presses?

You need to regularly perform press maintenance to keep digital and offset presses in top shape. Digital presses require less routine upkeep but still need cleaning and software updates for maximum performance. Offset presses demand more frequent maintenance, including plate handling and ink system checks, which impact equipment longevity. Consistent maintenance ensures smooth operation, reduces downtime, and extends the lifespan of your printing equipment, ultimately saving you money over time.

Conclusion

Choosing between digital and offset printing depends on your needs. Digital offers quick turnaround and cost-efficiency for small runs, while offset delivers superior quality for large volumes. Think of digital as the fast, flexible option, perfect for urgent jobs and customization. Offset, on the other hand, is the reliable workhorse for high-quality, bulk printing. Your decision balances speed and versatility against quality and economy—each method has its place, just like different tools serve different projects.