3D printers in packaging prototyping let you create complex, customized designs quickly and cost-effectively. They enable rapid iteration of prototypes, helping you test materials, shapes, and functional features without the delays of traditional manufacturing. You can explore innovative ideas, fine-tune prototypes for durability and flexibility, and speed up your development process. If you want to discover how this technology can boost your packaging projects further, there’s more to explore ahead.

Key Takeaways

- Enables rapid, cost-effective creation of customized packaging prototypes for faster development cycles.

- Allows testing of various materials and complex geometries without traditional tooling delays.

- Supports design iteration and fine-tuning for enhanced durability, flexibility, and performance.

- Facilitates simultaneous production of multiple prototypes for comparative analysis.

- Accelerates market readiness by reducing time and costs in packaging development processes.

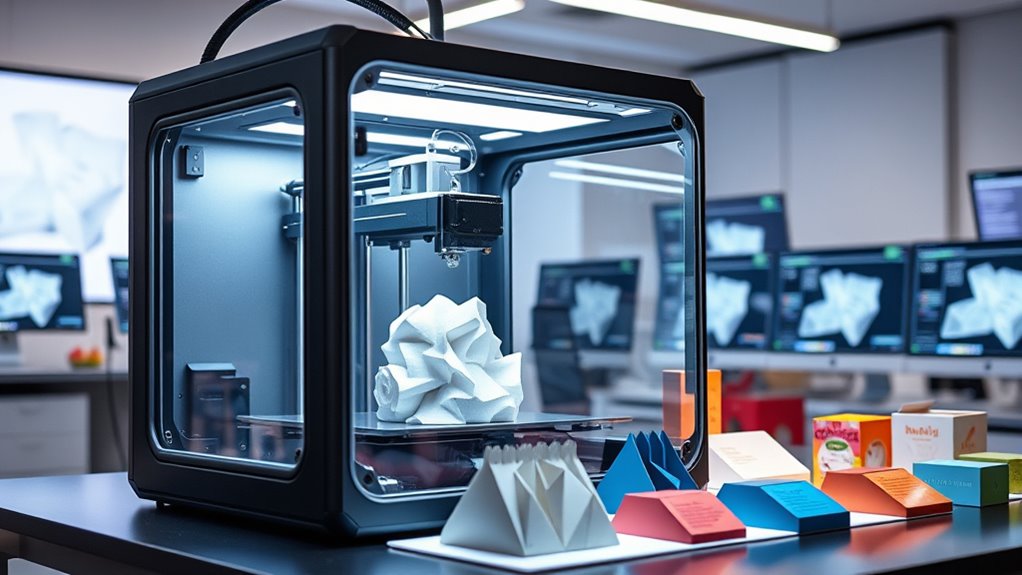

3D printers have revolutionized packaging prototyping by enabling rapid, cost-effective creation of custom designs. When you’re developing new packaging solutions, this technology allows you to experiment with various ideas quickly, giving you a competitive edge. One of the key advantages is your ability to choose from a wide range of materials, which directly impacts the success of your prototypes. Material selection is vital because it determines the durability, flexibility, and overall performance of your packaging. With 3D printing, you can test different plastics, resins, or even composite materials without the lengthy process and expense of traditional manufacturing. This flexibility lets you fine-tune your designs to meet specific requirements, whether you need a lightweight container or a tough, impact-resistant package.

Design flexibility is another major benefit of incorporating 3D printing into your prototyping process. Unlike traditional methods, which often require molds and tooling that limit design variations, 3D printing lets you create complex geometries and intricate details with ease. You can iterate your designs rapidly, making adjustments based on testing feedback without significant delays or costs. This level of customization encourages innovation, enabling you to explore unconventional shapes, internal structures, or integrated features that improve the functionality and aesthetic appeal of your packaging. As a result, you can develop prototypes that closely resemble the final product, reducing the gap between concept and production.

Moreover, 3D printing allows you to produce multiple versions of a design simultaneously, facilitating comparative testing and user feedback. You don’t need to wait for new molds or tooling; instead, you simply modify your digital model and print out the new version. This agility accelerates your development timeline and helps you identify the best design faster. Additionally, the ability to select different materials and adjust printing parameters means you can simulate how your packaging will perform under real-world conditions, addressing issues early in the design process. Utilizing raw material options can further enhance the performance and suitability of your prototypes for specific applications.

In essence, by leveraging material selection and design flexibility through 3D printing, you empower yourself to innovate more freely and efficiently. You can create highly customized prototypes tailored to your specific needs, test them thoroughly, and refine your designs without the constraints of traditional manufacturing. This technology reduces both time and costs, making it easier for you to bring new packaging solutions to market faster and with greater confidence. Embracing 3D printing in packaging prototyping transforms the way you approach development, offering you the tools to push boundaries and develop smarter, more effective packaging designs.

Frequently Asked Questions

What Are the Initial Costs of Implementing 3D Printing in Packaging?

The initial costs of implementing 3D printing in packaging depend on your cost analysis and technology integration. You’ll need to invest in a quality 3D printer, which can range from a few thousand to tens of thousands of dollars. Additional expenses include materials, software, and training. While the upfront investment is significant, it’s offset by faster prototyping, reduced waste, and improved customization, making it a smart long-term choice.

How Does 3D Printing Affect Overall Packaging Design Lead Times?

You’ll find that 3D printing markedly reduces packaging design lead times by enabling rapid digital customization and quick iteration. Instead of waiting weeks for traditional prototypes, you can produce and test designs in days, improving your workflow. Plus, the sustainability benefits of 3D printing mean less material waste, making your process more eco-friendly. This agility helps you bring packaging solutions to market faster and more efficiently.

What Materials Are Most Commonly Used in Packaging Prototypes?

You’ll find that materials like PLA, ABS, and PETG are your trusty chameleons in packaging prototypes, offering great material flexibility. They mimic real packaging’s texture and strength, letting you test designs thoroughly. Plus, many of these plastics have a lower environmental impact, making your prototypes eco-friendly. This combo helps you innovate confidently, knowing your materials are adaptable and kinder to the planet, all while bringing your packaging ideas to life.

Can 3D Printed Prototypes Be Used for Final Packaging Production?

You can’t typically use 3D printed prototypes for final packaging production because of sustainability concerns and regulatory compliance. These prototypes are great for testing designs and concepts, but they often don’t meet industry standards or environmental regulations. Using them in final production could lead to issues with safety, quality, or sustainability. Instead, stick to traditional manufacturing methods for final packaging, ensuring compliance and environmental responsibility.

How Do 3D Printers Handle Complex Geometries in Packaging Designs?

You’ll find that 3D printers handle intricate detailing and geometric complexity well, especially with advanced techniques like multi-axis printing and high-resolution nozzles. They can accurately reproduce complex shapes and fine features, allowing you to create prototypes that closely match your packaging design. While some very intricate geometries may require support structures or specific print settings, most modern 3D printers adapt easily to handle complex geometries efficiently.

Conclusion

By now, you see how 3D printers revolutionize packaging prototyping, making it faster and more cost-effective. Imagine testing a new box design in just hours, adjusting its size and shape instantly, like a company prototype a biodegradable package on the spot. With this technology, you can bring ideas to life swiftly, reducing waste and speeding up your product launch. Embrace 3D printing to stay ahead in innovative packaging solutions.