To protect electronics from static damage, you should choose the right anti-static packaging materials like static shielding bags or anti-static polyethylene bags with additives. These materials block or dissipate static electricity during handling, storage, and transit. Proper selection depends on your specific needs, product size, and vulnerability. Using anti-static packaging reduces the risk of ESD damage and saves costs. Keep exploring to discover how to optimize static protection features for your electronics.

Key Takeaways

- Static shielding bags with metallic layers provide effective electrostatic charge blocking for sensitive electronic components.

- Anti-static bags made from polyethylene with additives reduce static buildup but do not offer complete shielding.

- Conductive wraps and static-dissipative containers help prevent static damage during handling and storage.

- Proper selection of materials ensures durability and reliable static dissipation, protecting electronics during transit.

- Implementing grounding and proper handling practices minimizes electrostatic discharge risks, safeguarding sensitive devices.

Types of Anti-Static Packaging Materials

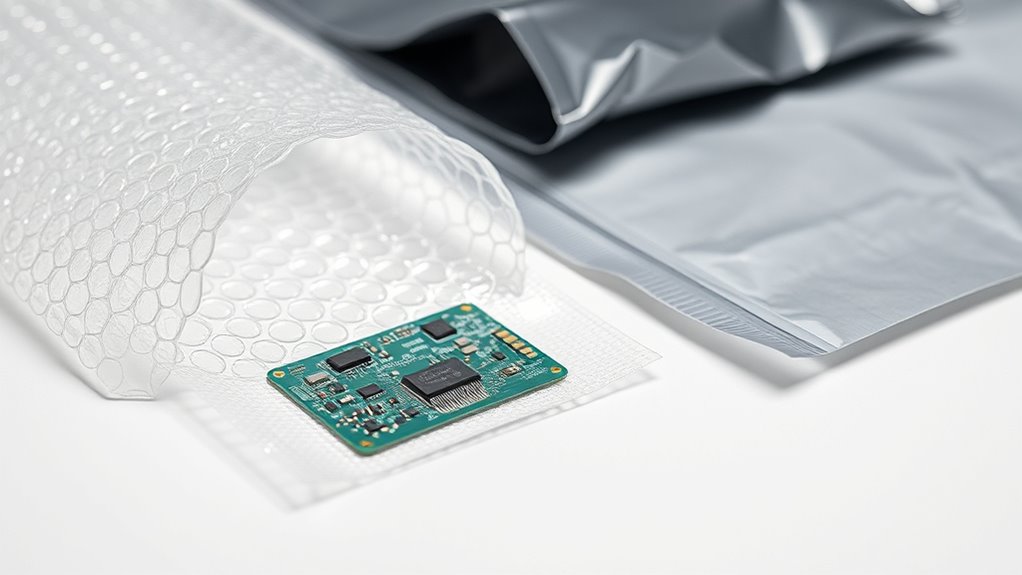

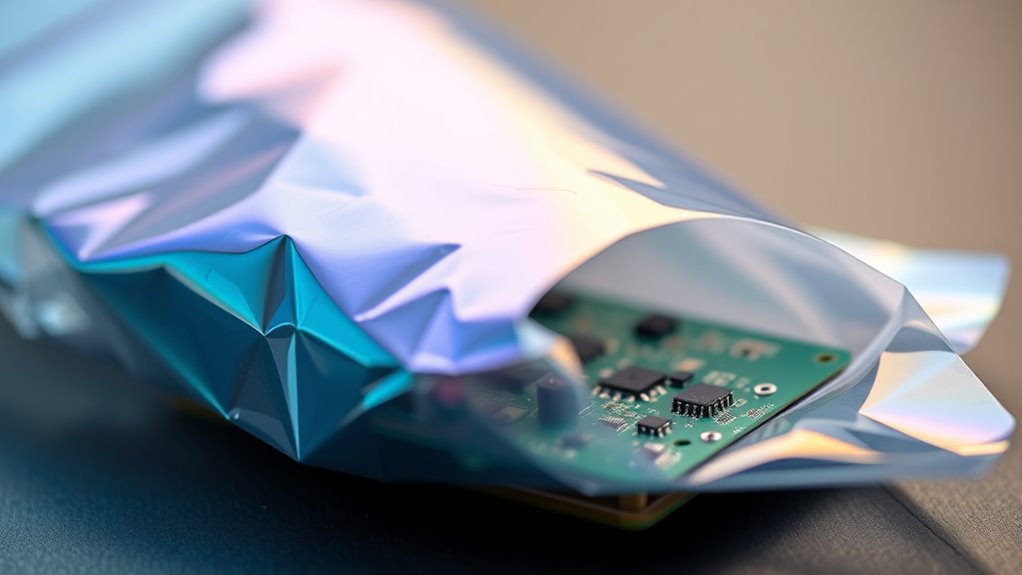

There are several common types of anti-static packaging materials designed to protect sensitive electronic components from static electricity. One primary type is static shielding bags, which have a metallic layer that blocks electrostatic charges, providing excellent protection for delicate parts. These bags are ideal for storing and transporting static-sensitive devices, as they prevent charge buildup from external sources. Anti static bags, made from polyethylene with antistatic additives, offer a more affordable option for less sensitive items. They reduce static buildup on the surface but don’t provide complete shielding. Other materials include conductive wraps and static-dissipative containers, each tailored for specific protection needs. Choosing the right type depends on the level of static risk your electronic components may encounter during handling and transit. Additionally, understanding the types of anti-static packaging materials can help in selecting the most appropriate solution for various applications.

How Static Electricity Damages Electronic Components

Static electricity can cause immediate damage to electronic components through electrostatic discharge (ESD), even if you can’t see it. Sensitive parts are vulnerable to sparks that can ruin circuits or degrade performance. To prevent this, you need to understand how ESD occurs and follow proper handling and storage tips. Additionally, using anti-static packaging materials can significantly reduce the risk of ESD-related damage.

Electrostatic Discharge (ESD) Effects

Electrostatic discharge (ESD) occurs when accumulated static electricity suddenly releases energy into electronic components, often causing immediate or latent damage. This sudden energy transfer can fry circuits, corrupt data, or weaken components over time. To prevent this, you need proper grounding techniques and awareness of packaging color codes, which indicate static sensitivity levels. Visualize this impact:

- A tiny spark destroys microchips instantly

- Damage remains hidden for months

- Data corruption occurs silently

- Device failures increase unexpectedly

Using anti-static packaging materials and following grounding techniques helps dissipate static safely. Pay attention to packaging color codes—typically, pink or purple indicates high static sensitivity, while blue or gray shows low risk. Proper handling minimizes the risk of damaging your electronics through ESD. Additionally, understanding anti-static materials can deepen your appreciation for the importance of protective packaging in electronics safety. Recognizing creative practice can inspire innovative approaches to designing better protective packaging solutions. Incorporating proper storage techniques can further enhance the effectiveness of static protection measures. Being aware of static charge buildup is crucial in preventing accidental discharges during handling and storage.

Sensitive Component Vulnerabilities

Static electricity can damage electronic components even without visible signs of harm, making them especially vulnerable during handling and transit. When static charge builds up, it can discharge suddenly, causing immediate damage or weakening sensitive parts over time. To prevent this, you should use proper grounding techniques, which safely direct static charges away from components. Without effective grounding, static charge buildup increases the risk of electrostatic discharge (ESD), potentially destroying microchips, capacitors, and other delicate parts. Be aware that even minor static accumulations can cause failures, so maintaining a controlled environment and using anti-static materials helps reduce vulnerabilities. Implementing proper grounding techniques is essential in minimizing static buildup and protecting sensitive components. Additionally, employing anti-static packaging materials can further reduce the risk of static discharge during transportation. Protecting sensitive components means understanding how static electricity affects them and implementing measures that minimize static charge buildup during handling and transportation. Furthermore, understanding the vulnerabilities of electronic components can help in designing more effective static protection strategies. Incorporating anti-static workstations and grounded tools can also significantly decrease static risks during assembly and repair processes. Recognizing the role of humidity levels in static charge accumulation can further enhance static control measures.

Prevention and Handling Tips

To effectively prevent damage to electronic components from static electricity, you need to follow proper handling and storage practices. Use grounding techniques to discharge static buildup, such as wrist straps or mats, when working with sensitive parts. Always handle components by edges, avoiding contact with conductive pins or surfaces. When disposing of packaging, guarantee proper disposal methods to prevent static charge accumulation. Store components in anti-static containers or bags when not in use. Be mindful of your environment: keep workspaces dry and free of static-prone materials. Proper packaging disposal prevents static build-up in waste, reducing risk. Remember, grounding techniques and careful handling are your best defenses against static damage. These simple steps help safeguard your electronics from costly static-induced failures. Additionally, understanding how sound vibrations influence cellular health can inspire innovative approaches to electronic protection. Incorporating anti-static materials that dissipate static charges can further enhance safety.

Features to Consider When Choosing Anti-Static Packaging

When choosing anti-static packaging, you need to contemplate the type of conductive materials that suit your needs. Durability is also key, as your packaging should protect sensitive components during handling and transit. By evaluating these features, you can select packaging that offers reliable static protection and long-lasting performance.

Conductive Material Options

Choosing the right conductive material for anti-static packaging depends on several key features. You should evaluate how well the material conducts electricity, its durability, and compatibility with your products. Metallic foams offer excellent conductivity and cushioning, making them ideal for sensitive electronics. Conductive polymers are lightweight, flexible, and easy to mold, suitable for custom packaging shapes. Additionally, assess the material’s resistance to environmental factors like humidity and temperature changes. Think about the manufacturing process and whether the material can be produced consistently at scale. Here are some options to consider:

- Metallic foams for cushioning and conductivity

- Conductive polymers for flexibility and lightweight protection

- Metalized films for barrier and static dissipation

- Conductive fabrics for reusability and adaptability

Being aware of data privacy challenges and how they influence material choices ensures better compliance and security in packaging solutions. Considering material sustainability is also important to meet environmental regulations and reduce ecological impact. Moreover, evaluating the manufacturing scalability of these materials is crucial for large-scale deployment and cost efficiency. Understanding the manufacturing processes involved in producing these materials can help optimize quality and consistency across batches. Recognizing supply chain considerations is vital to ensure timely availability of materials for production.

Packaging Durability Factors

Ever wondered what makes anti-static packaging stand up to the demands of protecting sensitive electronics? The key lies in packaging durability and material resilience. When choosing anti-static materials, you need packaging that can withstand handling, transportation, and storage without tearing or degrading. Look for sturdy materials that resist punctures, tears, and crushing forces, ensuring your electronics stay protected. Durable packaging maintains its protective properties over time, reducing the risk of damage from environmental factors like humidity and temperature fluctuations. Material resilience ensures the packaging can absorb shocks and impacts without compromising its anti-static qualities. Additionally, understanding packaging durability factors helps in selecting materials that can endure the rigors of shipping and storage, giving you peace of mind that your electronics are well-protected throughout their lifecycle. Prioritizing these durability factors helps you select reliable packaging that safeguards your electronics effectively throughout their lifecycle.

Benefits of Using Anti-Static Packaging in Electronics Manufacturing

Using anti-static packaging in electronics manufacturing offers significant benefits by protecting sensitive components from electrostatic discharge (ESD). It minimizes the risk of damage during handling, shipping, and storage, ensuring product reliability. You’ll find that proper grounding techniques and static shielding are essential features that enhance protection. These packaging materials:

Anti-static packaging protects electronics from ESD, ensuring reliability and reducing rework costs.

- Absorb and dissipate static charges effectively

- Prevent ESD from reaching delicate electronics

- Reduce costly rework and product failures

- Simplify compliance with industry standards

Best Practices for Handling and Storing Anti-Static Packaging

Proper handling and storage of anti-static packaging are essential to maintaining its protective properties. To prevent static buildup, always use grounding techniques when handling packaging materials. Store them in a controlled environment away from humidity, heat, and direct sunlight, which can compromise their effectiveness. Keep packaging flat and avoid folding or crushing to prevent damage. Use designated storage areas that are clean, dry, and free of static-generating objects. Here’s a quick reference:

| Handling Tips | Storage Environment | Grounding Techniques |

|---|---|---|

| Use ESD-safe gloves | Maintain 40-60% humidity | Wear wrist straps |

| Avoid folding | Keep away from heat sources | Use grounded workstations |

| Handle with care | Store vertically if possible | Ground mats on work surfaces |

Additionally, regular inspection and maintenance of storage areas help ensure that anti-static properties are preserved over time.

Innovations and Future Trends in Anti-Static Packaging

What are the latest innovations shaping the future of anti-static packaging? You’ll see smart materials revolutionizing protection, offering adaptive responses to environmental changes. These materials can adjust their conductivity or cushioning properties, enhancing electronics safety. Eco-friendly solutions are gaining momentum, with biodegradable and recyclable packaging reducing environmental impact. Companies are developing sustainable alternatives that don’t compromise performance. Additionally, smart packaging equipped with sensors can monitor conditions like humidity and static buildup in real-time, alerting you to potential risks before damage occurs.

Smart, eco-friendly anti-static packaging with adaptive materials and real-time sensor monitoring leads the future of electronics protection.

- Use of biodegradable plastics and recycled materials

- Integration of sensors for real-time static monitoring

- Development of smart materials with adaptive properties

- Adoption of eco-friendly, sustainable packaging options

Frequently Asked Questions

How Can I Identify Genuine Anti-Static Packaging From Counterfeit Products?

To identify genuine anti-static packaging, start by examining the product labeling for clear anti-static or ESD protection markings. Check the material composition—authentic anti-static packaging is made from specialized conductive or dissipative materials. Counterfeit products often lack proper labeling or use cheap, non-conductive materials. Trust reputable suppliers, and if in doubt, test the packaging with an anti-static wrist strap or meter to verify it provides proper static dissipation.

Are There Environmental Concerns Related to Anti-Static Packaging Disposal?

They say, “What goes around, comes around,” and that’s true for anti-static packaging disposal. You should know there are environmental concerns related to its disposal, like potential pollution from improper handling or non-biodegradable materials. The environmental impact can be minimized by recycling or choosing eco-friendly options. Always dispose of anti-static packaging responsibly to help reduce environmental impact and support sustainability efforts.

What Are the Cost Differences Between Various Anti-Static Packaging Materials?

When comparing anti-static packaging materials, you’ll notice differences in cost and material durability. Conductive foam tends to be more expensive but offers excellent protection and durability, making it suitable for high-value electronics. ESD-safe bags are more affordable and provide decent protection, while static shielding bags balance cost and durability effectively. Your choice depends on balancing budget constraints with the level of protection needed for your electronic components.

How Do Anti-Static Bags Affect Recycling Processes?

When you recycle items in anti-static bags, you might cause recycling contamination because these bags aren’t always compatible with standard recycling streams. Their presence complicates material separation, requiring extra steps or specialized processes. To avoid this, always check if anti-static bags are recyclable in your area or consider removing electronics from the bags before recycling. Proper disposal helps maintain efficient recycling processes and reduces environmental impact.

Can Anti-Static Packaging Be Reused Without Losing Effectiveness?

Like a cherished keepsake, you might wonder if anti-static packaging can be reused without losing its effectiveness. While some bags may retain their material durability and reusable effectiveness after careful handling, most tend to degrade over time, especially with multiple uses. To guarantee maximum protection, it’s best to assess the condition of the bags regularly, replacing them when their anti-static properties weaken, much like tending to a delicate treasure.

Conclusion

By choosing the right anti-static packaging, you’re safeguarding your electronics and staying ahead of the curve. Remember, a stitch in time saves nine—investing in quality materials now prevents costly damage later. Staying informed about the latest innovations and best practices guarantees your components stay protected, like a fortress against static threats. Don’t put all your eggs in one basket; prioritize proper handling and storage to keep your electronics safe and sound.