Single-wall corrugated boards have one layer of fluted medium, making them lightweight and suitable for lighter products or cost-conscious shipping needs. Double-wall boards feature two layers, providing extra strength and durability, ideal for heavier or fragile items. While double-wall options cost more upfront, they can save money in the long run by reducing damage and returns. To explore which option best fits your packaging requirements, keep going to learn more about their features and benefits.

Key Takeaways

- Single-wall boards are lightweight and cost-effective, suitable for lighter products and less fragile items.

- Double-wall boards offer increased strength and durability, ideal for heavier or fragile products needing extra support.

- Single-wall uses less material, reducing environmental footprint, while double-wall provides better protection and reduces product damage.

- Double-wall boards have higher initial costs but may save money long-term through fewer replacements and damage-related losses.

- The choice depends on product weight, fragility, protection needs, and sustainability goals, balancing cost and durability.

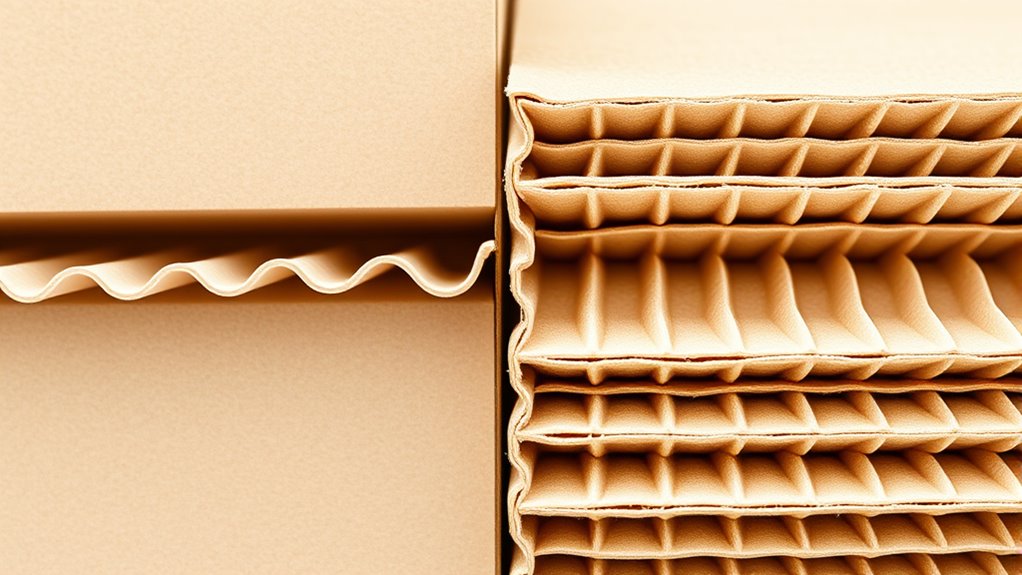

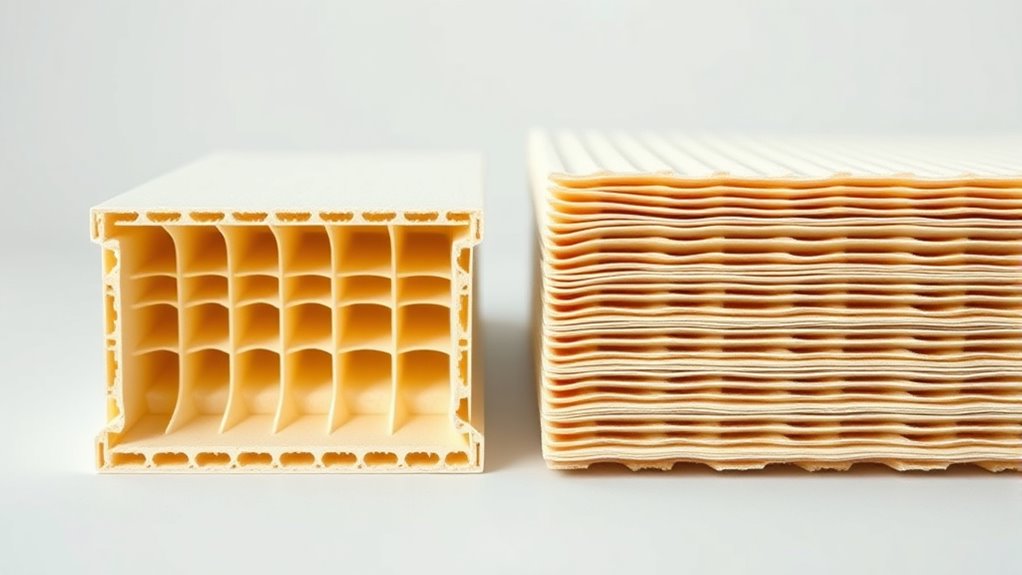

When choosing the right corrugated board for your packaging needs, understanding the differences between single-wall and double-wall options is essential. Both types serve specific purposes, but knowing their features helps you make an informed decision that balances eco-friendly options and cost efficiency. Single-wall corrugated boards consist of a single layer of fluted medium glued between two liners. They’re lightweight, flexible, and generally more affordable, making them ideal for lighter products and shipping needs where cost is a primary concern. Because they use less material, they tend to have a smaller environmental footprint, aligning with eco-friendly options. If sustainability is a priority, single-wall boards are a good choice, especially when your packaging doesn’t require high durability or heavy-duty protection. Additionally, their ease of customization allows for versatile branding and printing options, enhancing product presentation.

Double-wall corrugated boards, on the other hand, add an extra layer of fluted medium between two liners, providing increased strength and durability. This design makes double-wall options suitable for heavier or more fragile items that need extra cushioning and support during transit. They are notably more robust than single-wall boards, reducing the risk of damage and the need for additional packaging or padding. Although they use more material, which can increase costs, their enhanced protective qualities can actually lead to cost efficiency in the long run. You might find that using double-wall boards reduces product damage, lowers return rates, and diminishes packaging waste, ultimately saving you money and resources.

In terms of eco-friendly options, both single-wall and double-wall corrugated boards can be made from recycled materials and are recyclable themselves, supporting sustainability goals. However, because double-wall boards consume more raw materials, they may have a larger environmental impact if not sourced responsibly. That said, their durability can translate into fewer replacements and less waste over time, which balances out some of the environmental concerns. When weighing cost efficiency, consider the total cost of packaging—initial material costs, potential damage claims, and waste disposal. Single-wall boards are cheaper upfront but might not offer enough protection for heavier or delicate items, leading to higher costs through damages or additional packaging. Conversely, double-wall boards may have higher initial costs but can be more economical over time by providing better protection and reducing product loss.

Understanding material efficiency and how it impacts both environmental and economic factors is crucial for making the best choice for your packaging needs. Ultimately, your choice depends on your specific needs, product weight, fragility, and sustainability goals. If you prioritize eco-friendly options and lightweight packaging, single-wall corrugated boards are an excellent starting point. If your products demand more protection and durability, investing in double-wall options could prove more cost-effective and environmentally sound over the long haul.

Shipping and Packing Box, 12 x 12 x 48 Inch, Single Wall Corrugated Cardboard, 32 ECT Kraft, Recyclable, Ships Flat, 1 Pack

DIMENSIONS: Interior measurements of 12 x 12 x 48 inches, perfect for long items and specialized shipping needs

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Do Environmental Conditions Affect Corrugated Board Performance?

Environmental conditions directly impact corrugated board performance. You should know that moisture susceptibility increases in humid or wet environments, weakening the board and reducing its strength. Additionally, temperature sensitivity can cause the material to warp or become brittle under extreme heat or cold. To guarantee durability, it’s vital to safeguard your corrugated boards from moisture exposure and temperature fluctuations, especially if you’re using them in challenging environments.

What Are the Recycling Differences Between Single-Wall and Double-Wall Boards?

Recycling single-wall and double-wall corrugated boards is like sorting different puzzle pieces—you need the right process. Single-wall boards are easier to break down and recover materials from because their simpler structure allows for more efficient recycling processes. Double-wall boards, with extra layers, require more intensive material recovery efforts. Overall, single-wall boards generally recycle more efficiently, making them a more eco-friendly choice for sustainable packaging.

Are There Specific Industries That Prefer Double-Wall Over Single-Wall?

You’ll find that industries with higher protection needs, like electronics or fragile goods, prefer double-wall boards due to their added strength and durability. These industries often have specific requirements for material preferences that justify the extra cost. You should consider double-wall options if your products demand superior cushioning and stability during transit, ensuring your packaging meets industry-specific standards and effectively safeguards your shipments.

How Does Board Weight Impact Transportation Costs?

Think of board weight as the heartbeat of your shipping costs. Heavier boards act like a weighty anchor, dragging your transportation expenses downward, while lighter options glide more easily across routes. By choosing the right material, you optimize costs and streamline logistics. Material selection becomes a strategic dance, ensuring your packaging supports cost optimization without sacrificing strength, ultimately making your supply chain more nimble and cost-effective.

Can Custom Sizes Influence Board Strength and Durability?

Yes, custom dimensions can influence board strength and durability. When you choose specific sizes, you can optimize the structural integrity of your corrugated boards by adjusting the fluting and liner thicknesses to suit your needs. Properly designed custom sizes guarantee your packaging remains sturdy during handling and transit, reducing damage. By tailoring dimensions, you enhance durability, providing better protection and maintaining the quality of your products throughout the supply chain.

Box USA Shipping Boxes 24"L x 18"W x 12"H 10-Pack Large Double Walled Corrugated Boxes for Shipping, Packaging, Moving, Storage Box for Home or Business, Strong Wholesale Bulk Boxes

MOVING SUPPLIES – Boxes for apartment, school classroom, house and small business moves, for bedroom, clothing, books, household,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Think of single-wall and double-wall corrugated boards as shields in a battle. The single-wall is like a nimble knight, quick to move but with less armor, ideal for lighter loads. The double-wall, on the other hand, is a sturdy fortress, offering stronger protection for heavier items. Choose your shield wisely based on your needs—whether speed or strength. Just remember, the right choice keeps your goods safe, like a trusted guardian in the chaos of delivery.

Corrugated Moving and Storage Box for 12 Bottles, Fragile – 10 Pack

Durable Construction: This corrugated moving box is designed to withstand the rigors of relocation, ensuring your fragile items…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

The Boxery Moving Boxes 10-Pack Medium | 18x14x12 inch Brown/Kraft Corrugated Cardboard Packing, Moving & Storage for Business/Home – Durable – Eco-Friendly, Recyclable – Made in the USA

Cardboard box in Medium (10-pack), each measuring 18 x 14 x 12 inches

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.