If you’re choosing between cardboard and corrugated materials, it’s important to know their differences. Cardboard is a smooth, single-layer paperboard perfect for displays and lightweight packaging. Corrugated features layered fluted sections with liners, making it stronger and ideal for shipping heavy or fragile items. Corrugated usually costs more but provides better protection. To find out which fits your needs best and the advantages of each, explore more details ahead.

Key Takeaways

- Corrugated is layered with flutes and linerboard for added strength, while cardboard is a single thick paperboard surface.

- Corrugated offers superior durability and impact resistance, making it ideal for heavy or fragile shipping loads.

- Cardboard provides a smooth surface, better suited for retail displays and customizable branding.

- Recycling cardboard is simpler and more energy-efficient compared to the layered corrugated material.

- Use cardboard for lightweight, aesthetic displays; choose corrugated for heavy, protective shipping applications.

What Is Cardboard? Characteristics and Composition

Cardboard is a thick, sturdy paper-based material widely used for packaging and storage. Its composition typically involves layers of pressed paperboard, making it lightweight yet durable. However, recycling challenges arise because cardboard often contains coatings, inks, or adhesives that complicate the recycling process, leading to higher costs and waste management issues. Manufacturing costs can also be influenced by the quality of raw materials and the complexity of production processes, which affect overall efficiency. Despite these challenges, cardboard remains popular because it’s biodegradable and recyclable, making it an eco-friendly choice when properly processed. Its versatility and affordability make it ideal for various packaging needs, but understanding its composition helps clarify why certain recycling and manufacturing issues exist.

Understanding Corrugated Material: Structure and Types

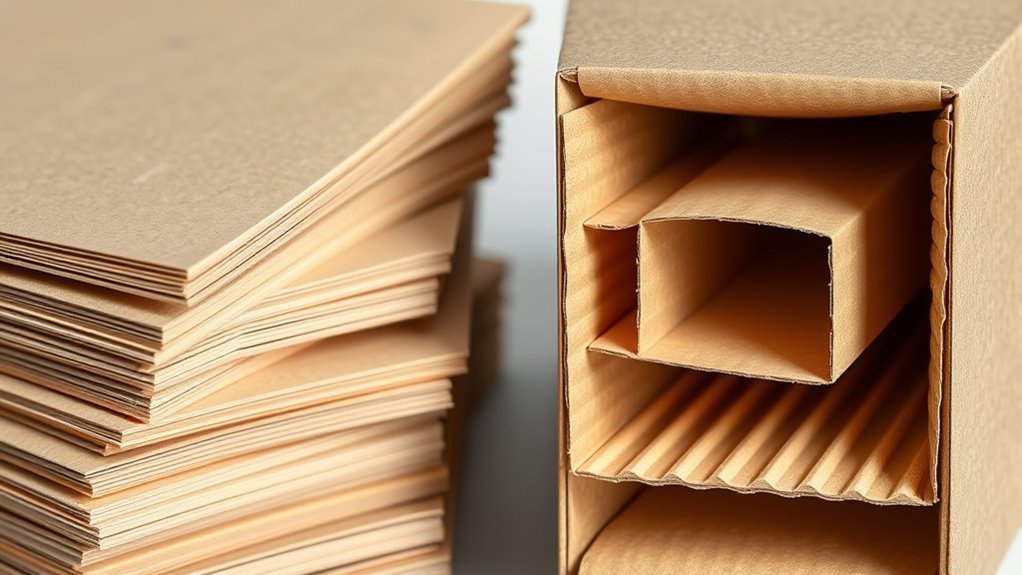

Corrugated material consists of multiple layers that give it strength and durability. You’ll find common types like single-wall, double-wall, and triple-wall, each suited for different packing needs. Understanding these layers and types helps you choose the right material for your specific application. Additionally, selecting the appropriate corrugated type can also improve your workspace organization and efficiency, especially when considering workspace productivity and the need for durable, versatile storage solutions. The different layers contribute to the material’s structural integrity, making it suitable for various demanding environments. Recognizing the vibrational energy of materials can also help in selecting the best type for specific handling and transportation requirements. Furthermore, the layered structure of corrugated material enhances its ability to absorb shocks and impacts during transit.

Corrugated Material Layers

Understanding the layers that make up corrugated material is essential to grasp its strength and versatility. The layer composition typically includes three parts: the fluted medium, the linerboard, and sometimes a liner or additional reinforcement. The manufacturing process shapes these layers into a sturdy, lightweight structure. During production, a flat sheet of linerboard is pressed against a rolling, corrugated medium to form the flutes, then glued together. This layered design creates a strong core that absorbs impact and resists compression. The specific arrangement and thickness of each layer influence the material’s durability and flexibility. Recognizing how these layers come together helps you select the right corrugated material for your packaging needs, ensuring ideal protection and performance. Additionally, understanding the layer structure can help in customizing the material for specific applications. Furthermore, advancements in AI Security technologies are continuously improving how these materials can be monitored and tested for quality assurance in manufacturing processes. Being aware of material properties also allows manufacturers to optimize the performance of corrugated products for diverse environments and uses.

Common Corrugated Types

Have you ever wondered why there are different types of corrugated materials? The most common types include single-wall, double-wall, and triple-wall corrugated board, each designed for specific strength and durability needs. Single-wall offers lightweight protection, ideal for shipping lightweight items, while double-wall provides extra strength for heavier products. Triple-wall corrugated is used for very heavy or bulky loads, offering maximum durability. These different types also bring recyclability benefits, as they’re widely accepted in recycling programs and can be reused or recycled efficiently. Considering material cost, single-wall is the most affordable, whereas double- and triple-wall options tend to be more expensive but offer better protection. The contrast ratio of the material can also influence its suitability for specific packaging applications, especially when visual inspection of the contents is necessary. Understanding these types helps you choose the right corrugated material for your packaging needs, balancing cost and durability.

Key Differences Between Cardboard and Corrugated

While both cardboard and corrugated materials are commonly used in packaging, they differ considerably in structure and strength. Cardboard is typically made from a single layer of thick paperboard, offering a smooth surface that enhances packaging aesthetics. Corrugated material, however, consists of fluted cardboard sandwiched between linerboards, providing superior durability and stacking strength. This structural difference makes corrugated ideal for shipping heavier or fragile items, while cardboard is better suited for retail displays and lightweight packaging. Cost considerations also vary; corrugated often costs more due to its layered design and manufacturing process but provides better protection. Additionally, understanding the automation in business can help optimize packaging processes for efficiency and scalability. Understanding these key differences helps you choose the right material based on your packaging needs, balancing aesthetics, strength, and budget.

Common Uses for Cardboard Packaging

Are you wondering where cardboard packaging fits into your product display or shipping plans? Cardboard is a versatile choice for many applications due to its ease of customization. You can easily add branding, logos, or specific designs to match your product’s look, enhancing brand recognition. Its lightweight nature also makes it a cost-efficient option for shipping, helping you reduce transportation expenses. Cardboard boxes are ideal for retail displays, gift packaging, and storage solutions—perfect when you need a simple yet effective way to present your products. Plus, the ability to customize cardboard ensures your packaging aligns with your branding, making it more appealing to customers. Additionally, understanding the difference between cardboard and corrugated materials can help you choose the best packaging for your specific needs. Corrugated packaging is often more durable and better suited for heavy or fragile items, providing extra protection during transit. This durability is especially important when considering survivalism principles like protecting essential supplies and ensuring safe transport. Overall, cardboard’s adaptability and affordability make it a popular choice for many business needs.

Ideal Applications for Corrugated Shipping Solutions

Corrugated shipping solutions excel when protecting heavy or fragile items during transit, making them ideal for e-commerce, manufacturing, and wholesale distribution. They streamline shipping logistics by offering strong, lightweight protection that reduces damage risks. Additionally, corrugated materials are versatile enough to be used in retail displays, enhancing product presentation and customer engagement. Here are some ideal applications:

Corrugated solutions protect fragile and heavy items while enhancing retail displays and streamlining logistics.

- Shipping heavy machinery or appliances that require sturdy, reliable packaging.

- Sending fragile glassware or electronics, where impact resistance is vital.

- Creating retail displays that are durable, customizable, and easy to assemble.

- Vetted for their eco-friendly and recyclable qualities, making them a sustainable packaging choice.

- Incorporating advanced fraud detection techniques in supply chain management can help prevent theft and ensure secure delivery, especially for high-value shipments.

- For added protection, choosing customized corrugated solutions can optimize packaging for specific items, further reducing the risk of damage during transit.

- The use of recyclable materials not only supports environmental sustainability but also aligns with growing consumer demand for eco-conscious packaging options.

Strength and Durability: Comparing Cardboard and Corrugated

When comparing the strength and durability of cardboard and corrugated materials, it’s clear that corrugated offers superior resilience for demanding applications. Corrugated’s layered structure provides better support, making it ideal for industrial applications where heavy loads or impact resistance matter. Cardboard, while lighter and more aesthetic, tends to bend or tear under stress. For instance, consider the following:

| Feature | Cardboard | Corrugated |

|---|---|---|

| Industrial applications | Limited, light-duty use | Heavy-duty packaging, shipping |

| Aesthetic appeal | Smooth surface, attractive | Rugged, structural look |

| Durability | Moderate, prone to damage | High, resistant to crushing |

Additionally, Honda Tuning components emphasize the importance of using durable materials for performance enhancements, highlighting how structural integrity can impact overall functionality. Proper material selection is essential for ensuring longevity and effectiveness in various applications, especially when handling heavy loads or demanding environments. Selecting the right material can also contribute to cost efficiency by reducing the need for frequent replacements or repairs. Understanding the material properties helps in making informed choices for different needs, and considering material strength is crucial when selecting materials for demanding uses.

Environmental Impact and Recycling Options

Recycling processes for cardboard and corrugated materials vary in efficiency, impacting how much waste is repurposed. Choosing eco-friendly options can reduce environmental harm and conserve resources. Understanding their environmental footprints helps you make better decisions about which material to use.

Recycling Processes and Efficiency

Ever wondered how efficient the recycling processes for cardboard and corrugated materials truly are? The efficiency comparisons reveal notable differences.

- Cardboard recycling involves fewer steps, making it quicker and energy-efficient.

- Corrugated recycling requires separating liners and flutes, adding complexity.

- Both materials can be recycled multiple times, but the quality degrades over cycles.

These factors influence the overall recycling processes, affecting environmental impact. Cardboard’s streamlined process minimizes waste and energy use, boosting efficiency. Corrugated’s additional handling can reduce efficiency slightly, but it remains highly recyclable. Understanding these differences helps you choose materials with better recycling outcomes. Overall, both materials support sustainable practices, but cardboard’s simplicity often makes it the more efficient option in recycling systems.

Eco-Friendly Material Choices

Choosing eco-friendly materials is essential for reducing environmental impact and promoting sustainability. When selecting between cardboard and corrugated options, consider biodegradable options that break down naturally, minimizing waste in landfills. Both materials can be produced from renewable resources like sustainably harvested trees or agricultural byproducts, making them more sustainable choices. Using renewable resources helps conserve non-renewable materials and reduces energy consumption during production. Look for suppliers that prioritize recycled content and biodegradable coatings to enhance environmental benefits. These eco-friendly choices not only lessen your carbon footprint but also support a circular economy by enabling easier recycling and composting. By prioritizing biodegradable options and renewable resources, you actively contribute to a healthier planet and foster environmentally responsible practices.

Environmental Impact Comparison

When evaluating the environmental impact of cardboard and corrugated materials, it’s important to contemplate how each one affects the planet through their production, use, and disposal. A biodegradability comparison shows that both materials decompose naturally, but corrugated cardboard tends to break down faster due to its structure. A carbon footprint analysis reveals that corrugated cardboard generally has a lower impact because it uses less material and energy during manufacturing. To illustrate:

- Corrugated cardboard typically requires less raw material, reducing resource depletion.

- Recycling options are widely available for both, but corrugated often enjoys higher recycling rates.

- Disposal methods influence environmental impact, with both being biodegradable but corrugated’s layered design aiding faster decomposition.

Choosing the Right Material for Your Packaging Needs

Selecting the right packaging material is essential to protecting your products and meeting your business needs. Consider whether packaging aesthetics matter—do you want a sleek, professional look or a more rugged appearance? Cost considerations also play a vital role; some materials are more budget-friendly, while others offer premium protection. To help you decide, here’s a quick comparison:

| Feature | Cardboard | Corrugated |

|---|---|---|

| Packaging aesthetics | Often more polished and presentable | More practical, less focus on appearance |

| Cost considerations | Usually cheaper for small-scale needs | Slightly more expensive but durable |

| Strength & protection | Adequate for lightweight items | Best for heavy or fragile products |

| Customization options | Easier to print and customize | Limited customization possibilities |

Choose based on your product’s needs and presentation goals.

Frequently Asked Questions

How Do Cost Differences Influence Choosing Between Cardboard and Corrugated?

When choosing between cardboard and corrugated, cost differences play a big role in your decision. Corrugated usually offers better cost efficiency for shipping and durability, making it ideal for heavier items. Cardboard is cheaper upfront but may not hold up well over time. Consider your budget considerations and the item’s protection needs. If you want long-term savings and strength, corrugated might be your best choice; for lighter, short-term use, cardboard could suffice.

Are There Specific Industries That Prefer One Material Over the Other?

Did you know that over 90% of products are shipped in corrugated boxes? Industry preferences heavily influence material selection; retail and e-commerce favor corrugated for durability, while food packaging often opts for cardboard for its eco-friendliness. Your choice depends on the industry’s needs for strength, cost, and sustainability. Understanding these preferences helps you select the best material to meet your specific packaging goals effectively.

How Does Moisture Affect the Integrity of Cardboard Versus Corrugated?

Moisture affects both materials, but you’ll notice cardboard absorbs moisture more easily, leading to structural weakening. Corrugated materials are designed with multiple layers, which help resist moisture absorption and maintain strength longer. When exposed to humid conditions or water, your cardboard may warp or disintegrate quickly, whereas corrugated boxes stay stronger longer, making them ideal for transport and storage where moisture exposure is likely.

Can Cardboard and Corrugated Be Recycled Together or Separately?

You can’t recycle cardboard and corrugated together because the recycling processes differ. Mixing them can cause contamination, reducing the quality of recycled materials and increasing environmental impact. Keep these materials separated to guarantee efficient recycling and minimize waste. Proper sorting supports sustainability efforts, helps conserve resources, and improves recycling outcomes. So, always separate cardboard from corrugated boxes before recycling to make sure they’re processed correctly and reduce your environmental footprint.

What Are the Best Practices for Storing Each Type to Maintain Quality?

Think of your storage area as a treasure chest—organized and protected. For cardboard, keep it dry, flat, and away from direct sunlight, following proper handling guidelines to prevent warping. Corrugated boxes thrive when stacked carefully in a cool, dry place, ensuring they don’t get crushed. Use storage techniques that maintain structural integrity, like avoiding excessive weight, so your boxes stay in prime condition, ready for reuse or recycling.

Conclusion

Think of cardboard and corrugated as two different tools in your packaging toolbox—one’s a sturdy brush, the other’s a layered sponge. Cardboard offers a solid, smooth surface, perfect for displays, while corrugated’s layered structure provides resilience for shipping. By choosing the right one, you’re building a fortress around your products, ensuring they arrive safe and sound. So, pick your material wisely, and let your packaging be as reliable as a trusty shield in battle.