Once you recycle paper, it’s collected and sorted to remove contaminants like plastic and staples. The paper then goes through de-inking to remove ink and coatings, followed by pulping, which breaks it down into fibers. These fibers are cleaned, screened, and blended to create a uniform pulp. Finally, the pulp forms new sheets, dries, and gets finished. If you want to discover more about each step, keep exploring the fascinating process behind paper recycling.

Key Takeaways

- Recycled paper undergoes sorting and contaminant removal using advanced techniques like optical sorting and magnetic separation.

- The cleaned paper is pulped with water and chemicals, breaking down fibers for reprocessing.

- The pulp is refined, blended, and screened to eliminate impurities and prepare it for sheet formation.

- Sheets are formed, dried, and finished, with quality verification to ensure strength, appearance, and purity.

- Final quality control guarantees the recycled paper meets industry standards and supports sustainable manufacturing cycles.

Collection and Transportation of Used Paper

To efficiently recycle paper, you first need to gather used paper from homes, offices, and businesses. Proper paper storage is essential to prevent contamination and maintain quality. Use designated bins or containers to keep paper organized and separate from other recyclables. Once collected, recycling logistics come into play; this involves scheduling pickups or drop-offs and coordinating transportation. Efficient logistics ensure the paper is transported swiftly to recycling facilities, reducing delays and damage. Keep paper dry and clean during storage and transit to facilitate effective recycling. Clear labeling and consistent collection routines help streamline the process. Managing paper storage carefully and optimizing recycling logistics are vital for recycling efficiency, ensuring a smoother, more sustainable cycle that benefits the environment and conserves resources. Additionally, understanding the cultural impact of recycling initiatives can encourage greater community participation and awareness. Proper handling also minimizes the risk of paper contamination, which is crucial for maintaining the quality of recycled materials and supporting the recycling process effectively. Incorporating advanced data analytics can further optimize collection routes and improve overall efficiency. Moreover, adopting innovative recycling techniques can enhance the recovery of materials and reduce waste.

Sorting and Classification of Recyclable Materials

When sorting recyclable materials, you’ll rely on different separation techniques like manual sorting, air classification, and machine sorting to keep materials pure. You’ll also need to evaluate the quality of paper through methods such as fiber analysis and contamination checks. These processes ensure that only suitable paper moves forward in the recycling cycle. Incorporating best practices in recycling helps improve the efficiency and effectiveness of paper recycling efforts. Additionally, implementing cybersecurity measures can help protect the data associated with recycling operations and ensure the integrity of the process. Employing advanced sorting technologies can further enhance the accuracy and speed of separating recyclable materials.

Material Separation Techniques

Have you ever wondered how recyclers efficiently sort paper from other materials? They use advanced material separation techniques to ensure purity. These methods include:

- Optical sorting that detects color and material types

- Air classifiers that separate lightweight paper from heavier items

- Magnetic separation for removing metal contaminants

- Fiber bonding techniques to identify paper fibers for recycling

- Chemical treatments to break down adhesives or coatings that interfere with sorting

These processes help improve sorting accuracy, making sure only suitable paper proceeds to pulping. Chemical treatments can loosen fiber bonds, aiding in separation, while fiber bonding analysis helps classify paper types. Additionally, material composition analysis plays a critical role in identifying different paper grades and contaminants. Advanced sensors are increasingly used to enhance detection precision in the sorting process. Incorporating machine learning algorithms can further optimize sorting efficiency by adapting to new material variations. Moreover, understanding gold IRA investment principles can assist recyclers in assessing the value of recovered materials for resale or reuse. Together, these techniques optimize the recycling process, guaranteeing cleaner input for manufacturing new paper products.

Quality Assessment Methods

Ever wonder how recyclers determine the quality of collected materials before processing? They use various assessment methods to guarantee only suitable paper enters the recycling stream. First, they examine fiber strength, checking if the paper fibers are intact or degraded, which impacts the final product quality. Fiber testing techniques help assess the integrity of the fibers in the paper. Color consistency is also vital; materials with uniform color are preferred, as mixed or stained paper can reduce the quality of recycled paper. Advanced technologies like optical scanners quickly identify and sort materials based on color and fiber properties. These assessments help recyclers classify materials accurately, minimizing contamination. By guaranteeing good fiber strength and consistent color, recyclers optimize the recycling process and produce higher-quality recycled paper, meeting industry standards and consumer expectations. Additionally, understanding contamination issues is crucial for maintaining the integrity of the recycling process and ensuring the final product’s quality. Recognizing material types also aids in selecting appropriate recycling techniques, leading to more efficient processing.

Cleaning and Removal of Contaminants

You need to understand how debris and ink are removed to guarantee clean paper pulp. Contaminant screening processes help identify and separate unwanted materials efficiently. Mastering these steps is essential for producing high-quality recycled paper. Essential oils for cleaning can also be utilized in certain processes to enhance the removal of residual contaminants and improve the overall purity of the pulp. Incorporating vacuum systems can further optimize contaminant separation by quickly removing fine particles from the pulp mixture. Proper maintenance of the equipment ensures consistent performance and prevents filter blockages that could hinder the cleaning process. Additionally, understanding recycling laws can ensure compliance and enhance the sustainability of the process. Ensuring accurate contaminant removal is crucial for maintaining the integrity and quality of the recycled paper.

Debris and Ink Extraction

How are contaminants like debris and ink effectively removed during paper recycling? You use a combination of processes focused on ink removal and debris extraction to guarantee clean paper stock. First, water-based flotation methods lift away lightweight debris like paper clips or plastic pieces. Second, specialized chemicals help loosen ink particles from fibers. Third, mechanical cleaning devices filter out larger debris such as staples or glued materials. Fourth, air classifiers separate lighter contaminants from the pulp. Additionally, advanced contaminant detection technologies improve the precision of debris and ink removal, enhancing the overall quality of recycled paper. Ultimately, centrifuges spin out remaining debris to ensure only pure fibers move forward. These steps work together to improve paper quality by thoroughly removing debris and ink. Additionally, advances in AI security can enhance detection and removal of contaminants in recycling facilities, ensuring higher purity of recycled paper. This meticulous cleaning process is essential for producing high-quality, recyclable paper, making sure contaminants don’t compromise the final product.

Contaminant Screening Processes

What are the key steps involved in screening and removing remaining contaminants from recycled paper? First, contaminant screening is essential to identify impurities like plastics, staples, and other non-paper materials. During impurity detection, advanced equipment such as optical scanners and magnetic separators help spot and separate these contaminants efficiently. These systems analyze the paper pulp in real time, ensuring only clean fibers move forward. Any lingering impurities are then removed through specialized processes like flotation or centrifugation, which further purify the pulp. This meticulous contamination control guarantees the recycled paper meets quality standards. By thoroughly screening for contaminants, you help ensure the final product is clean, safe, and suitable for manufacturing new paper products.

De-Inking Processes and Removal of Ink Residues

Have you ever wondered how paper recycling plants remove ink from used paper? The de-inking process is vital for producing clean, high-quality recycled paper. During ink removal, various techniques are combined to extract ink residues efficiently. Here’s what happens:

- Washing with chemicals to loosen ink particles from fibers

- Agitation to break apart ink films

- Flotation, where air bubbles lift ink away

- Centrifugation to separate ink from water and fibers

- Filtration to trap remaining ink residues

These steps guarantee that ink is effectively removed, preventing contamination in the recycled paper. De-inking not only improves the paper’s appearance and quality but also minimizes environmental impact by reducing ink waste in landfills. This process is essential for sustainable recycling practices.

Pulping: Breaking Down the Paper Fibers

Ever wonder how used paper is transformed into raw material for recycling? During pulping, the paper fibers are broken down into a slurry, allowing fiber bonding to be reestablished later. You start by mixing collected paper with water, creating a pulp. Chemical treatments are added to loosen the fibers and remove residual contaminants, making the fibers easier to separate. These chemicals also help improve fiber bonding, which is fundamental for creating strong recycled paper. The process involves mechanical agitation, which further breaks down the paper into tiny fibers. The goal is to produce a uniform, smooth pulp that can be cleaned and prepared for the next stages. This step is essential for turning discarded paper into a versatile raw material ready for refining and blending.

Refining and Blending of Recycled Pulp

Once the paper pulp has been properly broken down and cleaned, the next step is refining and blending to achieve the desired quality and consistency. You’ll add fiber reinforcement to strengthen the pulp, improving its durability and paper quality. Additive blending involves mixing in fillers, dyes, or chemicals to enhance properties like brightness or printability. During this stage, you also adjust the pulp’s consistency to ensure uniformity.

Key processes include:

- Incorporating fiber reinforcement for strength

- Mixing in additives for specific qualities

- Adjusting moisture and consistency levels

- Ensuring even distribution of blended materials

- Preparing the pulp for subsequent screening and filtering steps

This careful blending ensures the recycled pulp meets the standards needed for high-quality paper production.

Screening and Filtering to Achieve Uniformity

After blending the pulp, screening and filtering are essential steps to remove impurities and achieve a uniform consistency. During this process, screens with various mesh sizes catch larger contaminants like plastic pieces, staples, or ink particles, ensuring only clean fibers pass through. Filtering further removes tiny impurities, promoting better fiber reinforcement and enhancing paper quality. This step not only improves the paper’s strength and appearance but also reduces the environmental impact by minimizing waste and contamination in the recycling process. When impurities are effectively eliminated, the recycled pulp becomes more suitable for producing high-quality paper products. By maintaining a consistent and clean pulp, you help streamline manufacturing, cut down on waste, and support sustainable recycling practices.

Forming New Paper Sheets From Recycled Pulp

To form new paper sheets from recycled pulp, you first spread the cleaned and refined fibers evenly onto a moving screen or forming surface. The paper fiber properties, such as length and bonding ability, influence how well the fibers interlock and create a strong sheet. Recycling regulations guide the quality standards, ensuring contaminants are minimized during formation. As you work, consider:

- Adjusting the consistency of the pulp slurry for idealsheet formation

- Monitoring fiber distribution to prevent weak spots

- Managing water removal to maintain uniform thickness

- Controlling the fiber mat’s porosity for better bonding

- Ensuring compliance with safety and environmental standards

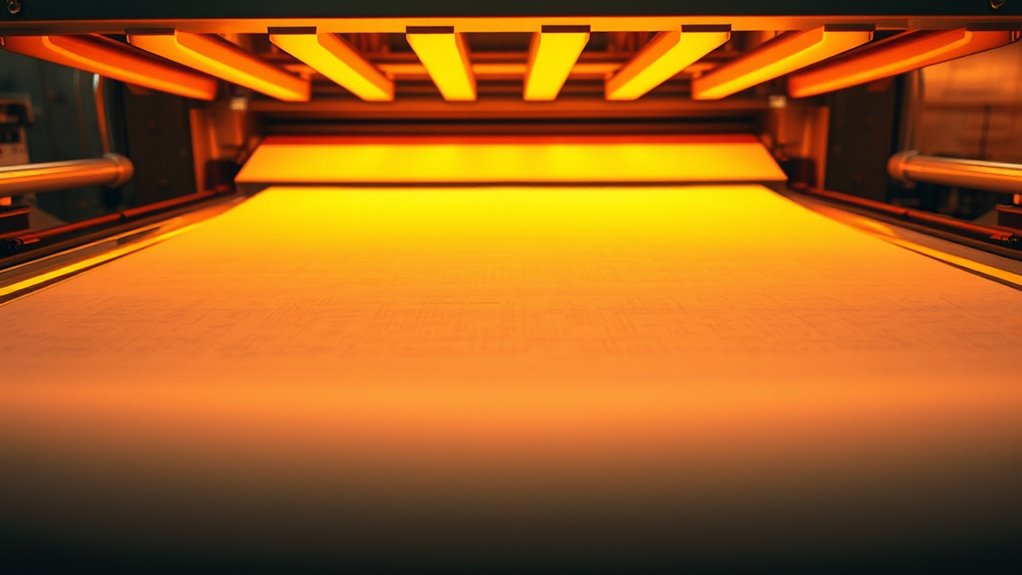

Drying and Finishing Processes

You’ll explore how air drying techniques help remove moisture efficiently from recycled paper. Surface finishing methods then enhance the paper’s smoothness and appearance. Together, these processes make sure your recycled paper meets quality standards and is ready for use.

Air Drying Techniques

Air drying is a simple yet *vital* step in the paper recycling process, ensuring that the paper dries evenly and maintains its quality. Proper air circulation helps remove moisture efficiently, preventing warping or uneven texture. Humidity control is *essential*; too much moisture slows drying, while too little can cause cracking. To optimize the process, you can:

- Use fans to promote consistent air flow

- Maintain moderate humidity levels in the drying area

- Space out sheets to avoid sticking

- Rotate stacks for even drying

- Monitor temperature to prevent rapid drying that could lead to cracks

Surface Finishing Methods

After the paper has been properly dried using effective air drying techniques, the next step is surface finishing to enhance its appearance and durability. During this process, you apply coatings that improve coating adhesion, ensuring the finish stays intact and resists wear. Surface finishing also involves treatments to boost surface gloss, giving the paper a smooth, shiny appearance that appeals to consumers. You might use rollers, presses, or other equipment to evenly distribute coatings and achieve a uniform finish. These methods not only improve visual appeal but also protect the paper from moisture, dirt, and handling damage. Carefully controlling these finishing processes results in a high-quality product with enhanced aesthetic and functional properties, ready for packaging or printing.

Quality Control and Preparation for Reuse

Ensuring the quality of recycled paper is a crucial step before it can be reused, and this process begins with thorough testing and sorting. You’ll assess paper quality by checking for contaminants, ink residues, and fiber integrity. This helps guarantee only suitable materials move forward in the recycling process. During sorting, you eliminate non-paper materials like plastics, metals, and adhesives that could compromise the final product. You also perform fiber analysis to verify the strength and suitability of fibers for reuse. Additionally, the paper is shredded into manageable pieces, making it easier to clean and de-ink. Proper preparation guarantees that the recycled paper maintains high quality and durability, ready for the next stage of manufacturing. This careful quality control preserves the integrity of the fibers and ensures a sustainable cycle.

Frequently Asked Questions

How Does Recycled Paper Compare in Strength to New Paper?

Recycled paper generally has slightly lower paper strength compared to new paper, but its recycled durability is still quite good. You might notice it’s a bit less sturdy, especially after multiple recycling cycles. However, advances in recycling technology improve recycled durability, making it suitable for many uses. So, while recycled paper may not match the strength of new paper perfectly, it’s still strong enough for most everyday applications.

Can Recycled Paper Be Used for All Types of Printing?

You might wonder if recycled paper suits all printing needs. While it’s great for many uses, recycling challenges can affect printing quality, especially for detailed images or professional documents. Recycled paper can sometimes be less smooth or have minor imperfections, which may impact print clarity. So, for high-quality printing, you’ll want to choose the right type of recycled paper, understanding its limitations and benefits for your specific project.

What Environmental Benefits Does Paper Recycling Provide?

You can help the environment by understanding the benefits of paper recycling. Recycling promotes sustainable practices and conservation efforts, reducing the need for virgin paper. This process saves trees, conserves water and energy, and lowers greenhouse gas emissions. By choosing to recycle, you actively contribute to protecting natural resources, supporting a healthier planet, and encouraging responsible waste management. Your actions make a real difference in fostering environmental sustainability.

Are There Limitations on the Colors or Types of Paper Recycled?

Imagine sorting through a rainbow of paper, yet realizing color restrictions and paper type limitations. You can’t recycle heavily colored or glossy papers because they contaminate the batch, affecting quality. Some paper types, like laminated or carbonless sheets, are also incompatible with recycling processes. These limitations help maintain recycled paper’s integrity, but they can also mean more waste ends up in landfills, making it essential to choose recyclable paper wisely.

How Many Times Can Paper Be Recycled Before Quality Declines?

You might wonder how many times you can recycle paper before its quality drops. Typically, fiber degradation limits recycling frequency to about five to seven times because each cycle weakens the fibers, reducing paper strength and quality. After multiple cycles, fibers become too short or fragile, making recycled paper less durable. So, while recycling helps, it’s important to recognize that repeated cycles eventually lead to diminished quality.

Conclusion

As you toss that paper into the recycling bin, imagine it journeying through busy sorting facilities and cleaning stations. Coincidentally, just as you finish your coffee, your paper may be transformed into fresh sheets, ready to hold new stories or notes. Recycling isn’t just about waste; it’s about turning yesterday’s paper into tomorrow’s possibilities. So next time, know that your small act helps create a cycle of renewal, quietly shaping a greener future.