By 2025, you’ll find a variety of compostable packaging options like plant-based bioplastics, mushroom-based materials, seaweed and algae-derived products, starch-based polymers, and innovative paper and cardboard solutions. Additionally, biodegradable polymers like PHA from microorganisms and edible packaging made from natural ingredients are gaining popularity. Advances in biodegradable films and coatings improve durability while maintaining compostability. To discover more about these eco-friendly solutions and how they’re shaping sustainable packaging, keep exploring further.

Key Takeaways

- Plant-based bioplastics, mushroom packaging, seaweed-derived materials, starch-based polymers, and innovative paper solutions are widely available in 2025.

- Advances include biodegradable coatings, eco-friendly laminates, and faster decomposition formulations for enhanced compostability.

- Emerging options such as mycelium composites, microbial bioplastics (PHA), and edible packaging are gaining market presence.

- Improved barrier properties and sustainable biopolymer technologies ensure functional, compostable packaging suitable for diverse industries.

- Market adoption continues to grow despite regulatory challenges, driven by sustainability goals and consumer demand for eco-friendly packaging.

Plant-Based Bioplastics Leading the Way

Plant-based bioplastics are quickly becoming a leading solution in sustainable packaging. These materials are derived from renewable resources like cornstarch, sugarcane, and cassava, making them a smart choice for eco-conscious brands. By prioritizing sustainable sourcing, manufacturers reduce reliance on fossil fuels and minimize environmental impact. You’ll notice that plant-based bioplastics not only break down more easily but also help lower carbon emissions during production. This shift to renewable inputs aligns with your goal of reducing your ecological footprint. As demand grows, more companies are adopting these eco-friendly options, ensuring that packaging solutions become more sustainable and responsible. Choosing plant-based bioplastics means supporting a circular economy while delivering packaging that aligns with your commitment to environmental stewardship. Additionally, understanding the cost of electric bikes and their components can inform sustainable transportation choices. Furthermore, ongoing advancements in biodegradable materials continue to improve their performance and affordability, making them an even more attractive option for businesses seeking eco-friendly packaging solutions. Moreover, innovations in biodegradability are making these materials more durable and practical for various applications. Research into new biopolymer formulations is also contributing to enhanced strength and flexibility, further broadening their usability in packaging.

Mushroom Packaging: An Eco-Friendly Alternative

Mushroom packaging offers a sustainable alternative to traditional materials by utilizing mycelium—the root structure of fungi—that naturally grows into dense, biodegradable forms. This eco-friendly fungi grows rapidly when combined with organic waste, creating a sturdy material suitable for packaging. It’s fully biodegradable fungi, breaking down in weeks without leaving harmful residues. You can customize mushroom packaging to fit various shapes, making it versatile for different products. Its fungal growth process consumes fewer resources compared to plastics. Additionally, the growth of fungi in this process can help reduce waste accumulation by transforming organic waste into useful packaging. This process also aligns with sustainable manufacturing practices aimed at reducing environmental impact. Furthermore, the use of fungi in packaging promotes biodegradability, ensuring items decompose naturally and safely. The entire process supports circular economy principles by turning waste into valuable materials. Here’s a quick comparison:

| Feature | Benefits |

|---|---|

| Fungal growth | Fast, sustainable, low-energy |

| Biodegradable fungi | Breaks down naturally |

| Eco friendly fungi | Reduces environmental impact |

| Custom shapes | Versatile packaging options |

| Production process | Less waste, minimal emissions |

This innovative packaging is transforming how you think about sustainable shipping solutions and aligns with environmentally friendly practices gaining popularity in 2025.

Seaweed and Algae-Derived Materials

Have you ever considered how seaweed and algae can revolutionize packaging? With sustainable seaweed cultivation, you can source raw materials that are fast-growing and require minimal land use. Algae extraction allows you to obtain biopolymers that decompose quickly and don’t harm the environment. These materials are versatile, offering strength and flexibility suitable for various packaging needs. Plus, they naturally contain antimicrobial properties, extending product shelf life. As demand shifts toward eco-friendly options, seaweed and algae-derived packaging provides a renewable alternative to plastics. Innovations are making these materials more cost-effective and scalable, helping businesses meet sustainability goals. By choosing seaweed and algae-based solutions, you’re investing in packaging that’s both environmentally responsible and aligned with future market trends. Incorporating vertical storage solutions and other organization strategies can further enhance sustainable practices by reducing waste and optimizing space usage in packaging facilities. Additionally, the integration of these materials can support reducing carbon footprints, aligning with broader environmental initiatives. Exploring biopolymer processing techniques can also improve the performance and durability of seaweed-based packaging options. Utilizing advanced manufacturing methods can further improve the efficiency and quality of biopolymer production, making these solutions more accessible for commercial use. Incorporating sustainable sourcing practices ensures that the entire lifecycle of the materials remains environmentally friendly and socially responsible.

Starch-Based Polymers and Their Applications

Starch-based polymers have gained prominence as sustainable alternatives to traditional plastics due to their biodegradability and renewability. You can find them in various packaging applications, especially where eco-friendliness matters. These polymers are often used as biodegradable coatings that extend product shelf life while reducing environmental impact. They also facilitate polymer recycling, making waste management more efficient. Besides packaging films, starch-based materials are suitable for creating compostable bags, trays, and food containers that break down naturally. Their versatility allows manufacturers to meet strict sustainability standards without sacrificing performance. By choosing starch-based polymers, you’re supporting a circular economy and helping reduce plastic pollution. With ongoing innovations, these materials are becoming a staple in the quest for fully compostable packaging solutions.

- Biodegradable coatings that protect products and enhance shelf life

- Easy integration into existing recycling streams

- Versatile applications from films to food containers

Paper and Cardboard Innovations for Compostability

You can explore how new sustainable materials are transforming paper and cardboard into more eco-friendly options. Innovative coating technologies help improve decomposition rates without compromising strength. These advancements make it easier for you to choose packaging that supports a healthier environment. Additionally, incorporating advanced purification technologies in manufacturing processes can further enhance the biodegradability of these materials, promoting a circular economy where resources are reused efficiently.

Sustainable Material Developments

Advancements in paper and cardboard materials are driving the development of more sustainable packaging options that can decompose naturally in composting environments. These innovations focus on meeting strict recycling standards while streamlining supply chain logistics for manufacturers. New materials often incorporate plant-based adhesives and biodegradable coatings to improve compostability without sacrificing strength or durability. You’ll find that these developments help reduce contamination risks in recycling streams and simplify sorting processes. Additionally, they enable easier integration into existing waste management systems, making composting more accessible. The use of Vetted renewable fibers that require less energy during production is also a crucial factor in enhancing the sustainability of these materials. Incorporating biodegradable coatings further enhances the ability of these materials to break down efficiently while maintaining their protective functions. Furthermore, implementing compostability standards ensures these materials meet environmental safety criteria and are suitable for commercial composting facilities. Emphasizing environmentally friendly manufacturing processes can also significantly reduce the overall carbon footprint of these innovative packaging solutions, especially when paired with advanced material testing to verify performance and compostability.

Enhanced Decomposition Processes

Innovations in paper and cardboard formulations are markedly enhancing their decomposition processes, making them more suitable for composting environments. These advancements increase biodegradation speed, ensuring materials break down rapidly without leaving harmful residues. By optimizing fiber treatments and selecting eco-friendly additives, manufacturers reduce the environmental impact of compostable packaging. Faster decomposition means your packaging contributes less to landfill waste and minimizes greenhouse gas emissions. Improved formulations also promote healthier soil by releasing nutrients more efficiently during breakdown. Additionally, understanding cost behavior analysis can help manufacturers balance quality and affordability in developing these eco-friendly materials. As a result, these innovations support a circular economy where packaging materials return safely to the environment. You can now choose paper and cardboard products that not only serve your packaging needs but also align with sustainability goals by decomposing swiftly and reducing overall environmental impact.

Innovative Coating Technologies

Innovative coating technologies are transforming paper and cardboard into more effective compostable packaging options by enhancing their environmental performance. By using biodegradable coatings and eco-friendly laminates, manufacturers improve barrier properties without sacrificing compostability. These coatings make packaging resistant to moisture, grease, and gases, extending shelf life and functionality. You’ll find these advances in sustainable packaging solutions that meet consumer demands and regulatory standards.

- Biodegradable coatings that break down naturally in compost conditions

- Eco-friendly laminates that provide moisture and grease resistance

- Processes that avoid toxic chemicals, ensuring safe composting and minimal environmental impact

Mycelium Composites for Packaging Solutions

Mycelium composites are emerging as a sustainable alternative to traditional packaging materials because they are biodegradable, renewable, and require minimal energy to produce. You can create these composites through mycelium cultivation, which involves growing fungal networks on agricultural waste. These fungal growth patterns bond the substrate tightly, forming a strong, lightweight material suitable for packaging. The cultivation process is quick and eco-friendly, often taking just a few days, and uses little water or energy. As the mycelium expands, it acts as a natural binder, eliminating the need for synthetic adhesives. Once fully grown, the material is dried and shaped into packaging forms. This innovative approach offers a compostable, low-impact solution that reduces waste and supports circular economy principles.

PHA (Polyhydroxyalkanoates): Biodegradable Plastics From Microorganisms

PHA plastics are designed to break down naturally in the environment, reducing pollution. You can produce these biodegradable materials using microorganisms through specific fermentation processes. Understanding these microbial methods helps you appreciate how PHA offers a sustainable alternative to traditional plastics.

Biodegradability in Nature

Have you ever wondered how certain biodegradable plastics break down naturally in the environment? PHA, or Polyhydroxyalkanoates, are produced by microorganisms and decompose through natural processes. When these plastics enter soil or water, native microbes break them down, returning nutrients to the environment. This process minimizes the ecological impact and supports soil health, making PHA a sustainable choice.

Key points include:

- PHA biodegrades faster than traditional plastics, reducing long-term pollution.

- Its breakdown enriches soil nutrients, benefiting plant growth.

- This natural decomposition process helps preserve ecological balance.

Microbial Production Processes

Microorganisms play a crucial role in producing biodegradable plastics like PHA through a natural fermentation process. During microbial fermentation, bacteria synthesize PHA as an energy storage compound when nutrients are limited. You can harness microbial synthesis by providing specific carbon sources, prompting microbes to produce PHA efficiently. This process involves cultivating microbes in controlled environments, optimizing conditions such as pH and temperature to maximize yield. As the microorganisms consume the feedstock, they convert it into PHA, which can then be extracted and processed into biodegradable plastics. These microbial production processes are sustainable alternatives to traditional plastics, reducing reliance on fossil fuels. By understanding and improving microbial fermentation techniques, you can support the development of eco-friendly packaging materials that decompose naturally after use.

Edible Packaging Options Gaining Traction

Edible packaging options are quickly gaining traction as sustainable alternatives to traditional materials. They not only reduce waste but also add a fun, functional element to the packaging experience. Companies are experimenting with edible coatings that protect food while enhancing flavor infusion, making snacks more appealing. These coatings can be made from natural ingredients like seaweed or rice, which are safe to eat and environmentally friendly.

Edible packaging reduces waste and adds fun, flavor-infused elements with natural, eco-friendly coatings like seaweed and rice.

You might find products like:

- Edible wraps infused with herbs or spices, adding flavor as you eat

- Fruit-based shells that serve as both packaging and a snack

- Thin, flavored films that complement the product inside

These innovations are transforming packaging from a waste issue into a tasty, eco-conscious feature you can enjoy.

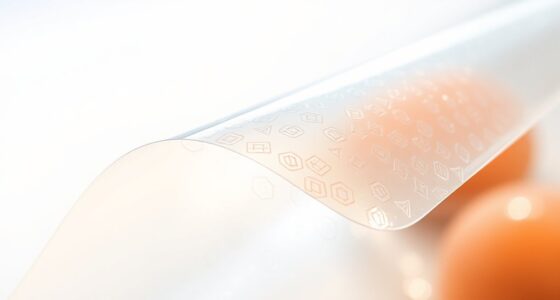

Innovations in Compostable Films and Wraps

Innovations in compostable films and wraps now incorporate advanced biopolymer technologies, making them stronger and more versatile. These new materials also boast enhanced barrier properties, helping to keep products fresh longer. As a result, you can expect more eco-friendly packaging options that don’t compromise on performance.

Advanced Biopolymer Technologies

Advancements in biopolymer technologies are transforming the landscape of compostable packaging by developing films and wraps that combine sustainability with performance. These innovations focus on optimizing the biopolymer lifecycle, ensuring materials break down efficiently after use. Researchers are also prioritizing sustainable sourcing, using renewable feedstocks to reduce environmental impact. New formulations improve flexibility, strength, and transparency, making compostable films more comparable to conventional plastics. These developments enable packaging that not only meets consumer demands but also aligns with eco-friendly practices. With ongoing research, biopolymer innovations are paving the way for cost-effective, high-performance materials that support circular economies. As a result, you’ll see more versatile, durable, and eco-conscious options in the marketplace, helping you reduce your carbon footprint while maintaining product integrity.

- Improved biodegradation rates through innovative polymer blends

- Use of renewable, sustainably sourced raw materials

- Enhanced mechanical properties for versatile applications

Enhanced Barrier Properties

Building on recent biopolymer innovations, enhancing barrier properties in compostable films and wraps is key to expanding their practical applications. Better barrier performance helps protect products from moisture, oxygen, and contaminants, making compostable packaging more competitive with conventional plastics. Overcoming recycling challenges remains critical, as many compostable films aren’t compatible with traditional recycling streams, which can hinder acceptance. To boost consumer acceptance, manufacturers focus on developing films that combine high barrier qualities with clear compostability, ensuring end-of-life disposal is straightforward. Innovations like bio-based coatings and multilayer structures aim to improve durability without sacrificing compostability. These advances not only extend shelf life but also address environmental concerns, making compostable packaging a viable, eco-friendly alternative in a growing market.

Challenges and Future Trends in Compostable Packaging

While compostable packaging offers promising environmental benefits, it faces several hurdles that could slow its widespread adoption. Consumer adoption remains a challenge, as many customers are unfamiliar with composting practices or skeptical about disposal methods. Regulatory hurdles also complicate things; inconsistent standards and lack of clear guidelines delay market growth. Additionally, ensuring compostability without compromising barrier properties can be difficult, affecting product performance. To overcome these issues, you’ll need to focus on educating consumers about proper disposal and advocating for clearer regulations. Future trends may include innovations in biodegradable materials that meet both environmental and functional needs, along with more unified standards to streamline adoption. Overcoming these challenges is essential for compostable packaging to become a sustainable mainstream solution.

Frequently Asked Questions

How Does Compostability Differ Between Various Biodegradable Packaging Materials?

You’ll notice that compostability varies among biodegradable packaging materials based on material durability and environmental impact. Some materials break down quickly in compost, reducing waste, while others last longer but may have a higher environmental impact during production. Your choice affects how efficiently the packaging decomposes and its overall sustainability. By understanding these differences, you can select eco-friendly options that balance durability with minimal environmental impact for better waste management.

Are There Any Limitations to Using Compostable Packaging for Certain Products?

Think of compostable packaging as a delicate dance partner—you need perfect harmony. You might face limitations with certain products, as their durability and chemical compatibility can be compromised. For example, very moist or chemically reactive items may not suit compostable materials, risking breakdown or contamination. So, you must evaluate each product carefully to verify it won’t undermine the packaging’s compostability or performance, avoiding a misstep in your sustainability efforts.

What Is the Typical Lifespan of Compostable Packaging in Different Environments?

The typical lifespan of compostable packaging varies based on environmental factors and its biodegradation rate. In compost conditions, it often breaks down within 90 to 180 days. However, in environments like landfills or aquatic settings, it might take much longer or not fully degrade. You should consider where the packaging will be used, as environmental factors considerably influence how quickly it biodegrades.

How Do Compostable Materials Impact Recycling and Waste Management Systems?

Ever wondered how compostable materials influence your recycling efforts? They can complicate recycling infrastructure, sometimes leading to contamination if not sorted properly. But, if managed well, they boost waste diversion, reducing landfill waste. Your actions matter—by understanding these impacts, you help guarantee compostables are processed correctly, supporting sustainability. The key lies in improving waste management systems, so compostable packaging becomes an asset, not a challenge, in your community’s environmental journey.

What Are the Cost Implications of Switching to Compostable Packaging Materials?

When you consider switching to compostable packaging, you need to do a cost analysis to understand the financial impact. While initial costs may be higher, you could save money long-term through improved waste management and potential subsidies. Keep in mind, your supply chain might need adjustments, which could add up. Overall, weighing these factors helps you decide if the environmental benefits justify the investment.

Conclusion

By 2025, you’ll see compostable packaging revolutionize how we protect our planet—it’s like a tidal wave of eco-friendly innovation! From plant-based bioplastics to mushroom and seaweed options, these materials are transforming waste into wonder. Embrace these solutions, because every choice you make can spark a massive shift toward sustainability. The future of packaging isn’t just green—it’s a game-changer, and you’re at the forefront of this incredible movement!