To secure your printing supplies, start by evaluating your needs and analyzing your past usage to prevent shortages or excess stock. Research reliable suppliers with strong certifications, good track records, and sustainable practices. Build solid relationships through clear communication and contracts, and regularly monitor quality and performance. Use technology to streamline ordering and reduce errors. Planning for risks and diversifying sources will keep your supply chain resilient—continue here to find more tips on creating a robust sourcing strategy.

Key Takeaways

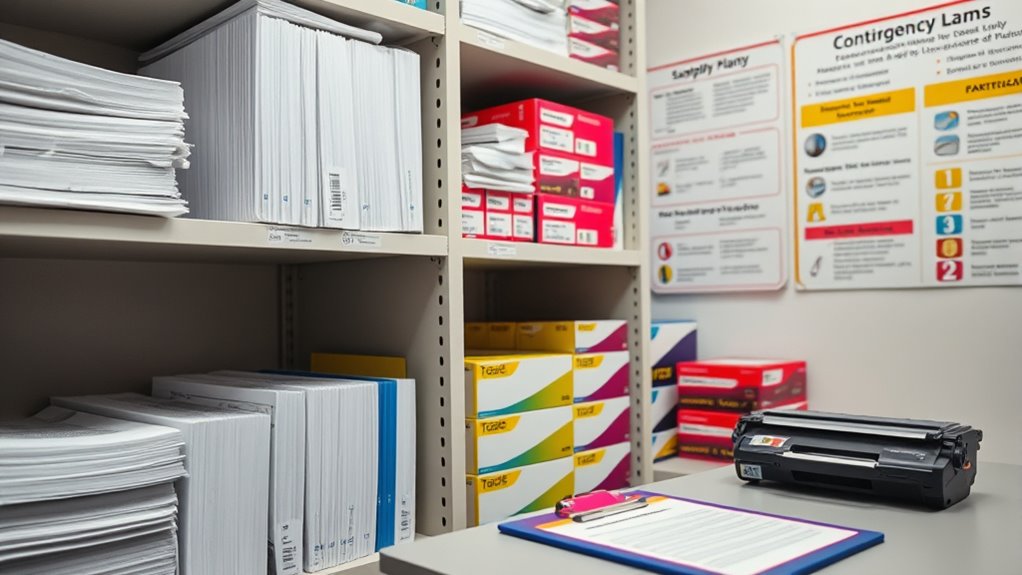

- Assess your printing needs regularly and develop contingency plans to handle supply disruptions.

- Build strong relationships with certified, reliable suppliers through audits and clear contractual agreements.

- Diversify your supplier base to reduce dependency and mitigate risks of delays or quality issues.

- Use technology and data analytics to monitor inventory levels and optimize procurement processes.

- Incorporate quality control measures and stay informed on market trends to ensure consistent, high-quality supplies.

Assessing Your Printing Supply Needs

Before ordering printing supplies, it’s essential to evaluate your current needs to avoid shortages or excess stock. Effective inventory management helps you determine how much stock you require and prevents overordering, which can lead to waste. Consider your typical printing volume, types of supplies used, and seasonal fluctuations. Incorporate sustainability practices by prioritizing eco-friendly options and reducing unnecessary inventory. Analyzing past usage patterns allows you to forecast future needs accurately, minimizing excess stock that may become obsolete or expire. Regularly reviewing your inventory ensures you stay aligned with your operational demands and sustainability goals. Understanding supply chain management principles can further optimize your inventory control. Additionally, being aware of product spoilage and storage life can help prevent waste of supplies that have expired or been compromised. Incorporating demand forecasting techniques can enhance your ability to anticipate fluctuations and adjust your orders proactively. Developing a comprehensive understanding of inventory turnover rates can also assist in maintaining optimal stock levels. Employing data-driven strategies can help you make more informed decisions, reducing waste and increasing efficiency. By carefully appraising your printing supply needs, you optimize inventory management, reduce waste, and support environmentally responsible practices within your supply chain.

Researching and Evaluating Potential Suppliers

To guarantee reliable supply and quality, you need to thoroughly research and evaluate potential printing supply vendors. Begin by checking their vendor certifications, which attest to their compliance with industry standards and quality management systems. Certifications like ISO or other relevant credentials indicate a commitment to consistent quality. Next, conduct supplier audits to assess their operations, production processes, and adherence to safety and environmental standards. During audits, look for transparency, responsiveness, and the ability to meet your demand reliably. Review their track record for delivering on time and handling issues swiftly. Combining certification verification with on-site or remote audits helps you identify suppliers who can consistently meet your quality and reliability requirements, ultimately strengthening your supply chain. Additionally, evaluating their unique and wicked planters can reveal their capacity for innovative and diverse product offerings, which may enhance your product portfolio. Considering their environmental practices can also provide insight into their commitment to sustainability and responsible manufacturing, aligning with your company’s values. Assessing their arts and crafts materials can help ensure they provide safe and high-quality components suitable for your projects. Incorporating insights from preppy dog names and other breed-specific preferences can also inform your supplier evaluation process, especially if your business involves specialized or themed products. Furthermore, assessing their approach to Glycolic Acid Benefits can ensure they prioritize product quality and safety standards, which is crucial for maintaining customer trust.

Building Strong Supplier Relationships

Building strong supplier relationships is essential for ensuring a stable and efficient supply chain. You can achieve this by emphasizing vendor certification, which verifies suppliers meet your quality and reliability standards. Maintaining open communication helps build trust and aligns expectations. Negotiation strategies are crucial; approach discussions with a collaborative mindset to secure favorable terms while fostering goodwill. Regularly evaluate supplier performance and provide feedback to strengthen your partnership. Showing appreciation for their efforts encourages loyalty and reliability. By investing in these relationships, you reduce disruptions and guarantee consistent access to high-quality printing supplies. Establishing a reliable supply chain also involves understanding industry standards and best practices to stay ahead of potential issues. Monitoring supplier compliance with regulations and standards further minimizes risks and enhances trust. Building a foundation of trust and transparency with your suppliers is key to long-term success. Incorporating clear contractual agreements helps formalize expectations and responsibilities, preventing misunderstandings. Remember, a dependable supplier network depends on mutual understanding, respect, and proactive engagement. Incorporating diverse anime movies into your entertainment repertoire can also foster positive relationships by sharing interests and experiences with your partners. Building these bonds now will pay off through smoother operations and long-term stability.

Implementing Quality Control Measures

Implementing effective quality control measures is essential for maintaining consistent printing supply standards. You need to regularly assess inventory management practices to identify potential issues early. Diversifying your suppliers ensures you aren’t reliant on a single source, reducing risks of delays or subpar products. Establish clear quality benchmarks and inspect supplies upon arrival. Consistent evaluation ensures your supplies meet standards, supporting smooth operations. Monitoring supplier performance metrics is crucial for maintaining supply chain reliability. Staying informed about market trends can help you anticipate supply disruptions or quality fluctuations.

Leveraging Technology for Supply Chain Management

By harnessing advanced supply chain management technologies, you can substantially improve the accuracy and efficiency of your inventory handling. Automation integration streamlines ordering processes, reduces manual errors, and accelerates response times. Data analytics provides real-time insights, helping you forecast demand and optimize stock levels. Incorporating sound vibrations into training modules can enhance staff engagement and retention of procedures. To maximize these benefits, consider:

- Implementing automation tools that connect suppliers and inventory systems seamlessly.

- Using data analytics dashboards to monitor supply chain performance continuously.

- Integrating automation with existing ERP systems for smoother workflows.

Additionally, understanding the importance of projector contrast ratio can help in selecting reliable equipment that ensures clear visuals, which is crucial for presentations and visual displays. Recognizing vetted – ID Times resources can also assist in identifying trustworthy suppliers and industry updates, further strengthening your supply chain strategies. Leveraging popular juice brands and health-conscious options can also inspire innovative product offerings and packaging improvements. These technologies allow you to make informed decisions quickly, reduce waste, and ensure reliable printing supplies. Leveraging automation integration and data analytics transforms your supply chain into a more agile, accurate, and cost-effective operation.

Planning for Contingencies and Risk Mitigation

Effective planning for contingencies and risk mitigation is crucial to guarantee your supply chain remains resilient in the face of disruptions. You should prioritize strong inventory management to ensure you have enough supplies during unexpected delays. Regularly review your inventory levels and adjust reorder points to prevent shortages. Additionally, diversify your supplier base to reduce dependency on a single source. Relying on multiple suppliers minimizes risks if one encounters issues, like delays or quality problems. Develop a clear contingency plan that includes alternative sourcing options and communication protocols. Keep close tabs on potential risks and stay flexible to adapt quickly. By proactively managing inventory and expanding your supplier network, you strengthen your supply chain’s ability to withstand unforeseen challenges.

Frequently Asked Questions

How Often Should I Review and Update My Printing Supply Contracts?

You should review and update your printing supply contracts at least annually to make certain they remain aligned with your needs. Conduct regular supplier evaluations during these reviews to assess performance, pricing, and delivery reliability. A contract renewal process helps you stay proactive, address any issues, and renegotiate terms if necessary. Staying diligent with these updates ensures you maintain a reliable supply chain and get the best value from your printing supplies.

What Are the Signs of a Declining Supplier Relationship?

You might notice a declining supplier relationship if communication becomes infrequent or unclear, making it hard to resolve issues quickly. Order consistency may also drop, with delays or errors becoming more common. If your supplier’s responsiveness decreases or quality issues increase, it’s a sign to review your relationship. Staying proactive with supplier communication helps you catch these signs early and address problems before they impact your printing supply chain.

How Can I Verify the Sustainability Practices of My Suppliers?

You might think verifying sustainability is as simple as trusting their word, but that’s like trusting a fox in the henhouse. Instead, check for sustainable certifications and ask if they use eco-friendly materials. Demand transparency about their practices, review third-party audits, and request proof of eco-conscious sourcing. This way, you guarantee your supply chain aligns with genuine sustainability efforts, rather than just greenwashing.

What Training Is Recommended for Staff Handling Supply Chain Disruptions?

You should train your staff on inventory management and risk assessment to handle supply chain disruptions effectively. Focus on teaching them how to monitor stock levels, identify potential shortages, and evaluate risks like supplier delays or shortages. Practical exercises in forecasting and contingency planning help them respond quickly. This way, your team stays prepared, minimizes disruptions, and keeps your supply chain resilient during unexpected challenges.

How Do Geopolitical Factors Influence Printing Supply Availability?

Imagine geopolitical factors as the winds steering a ship; they can swiftly change direction. International trade and political stability directly impact printing supply availability, causing delays or shortages. For instance, trade restrictions or conflicts can block essential raw materials. Staying informed of global political shifts helps you anticipate disruptions, ensuring you adapt your sourcing strategies proactively and keep your printing operations running smoothly despite unpredictable international currents.

Conclusion

By securing reliable printing supplies, you create a steady flow amid chaos. Imagine a ship confidently sailing through stormy waters, its anchor grounded in trusted suppliers. Without it, you drift aimlessly, vulnerable to disruptions. Building strong relationships and implementing quality checks act as your sturdy anchor, ensuring your supply chain remains resilient. Stay proactive, plan for risks, and visualize your supply chain as a dependable vessel, ready to weather any storm with confidence.