Paper is mainly made of cellulose fibers from plant sources like wood or recycled paper, which give it strength and flexibility. Lignin, a natural part of plant cell walls, adds rigidity but can cause yellowing and aging over time. Fillers such as clay or calcium carbonate improve surface quality, brightness, and opacity. Understanding how these components work together affects the durability, appearance, and sustainability of paper. Explore further to uncover how manufacturing choices influence these properties.

Key Takeaways

- Paper primarily consists of cellulose fibers derived from plant cell walls, providing strength and flexibility.

- Lignin is a natural component that adds rigidity but can cause yellowing and aging in paper over time.

- Fillers like calcium carbonate and kaolin enhance surface quality, opacity, and brightness of paper products.

- The balance of cellulose, lignin, and fillers determines paper durability, appearance, and environmental impact.

- Advances include eco-friendly, biodegradable fillers and nano-enhancements to improve strength and sustainability.

The Role of Cellulose in Paper Making

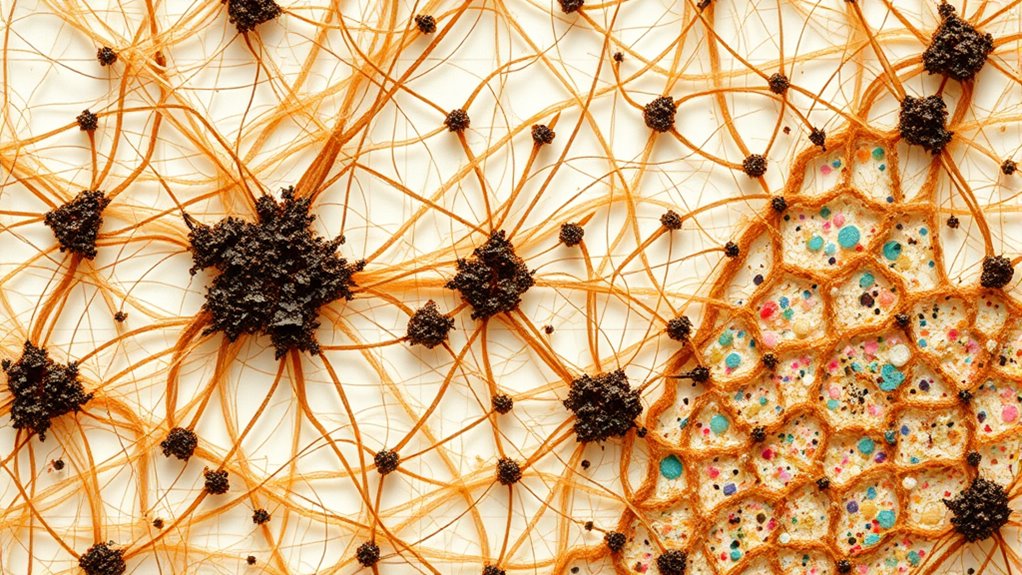

Have you ever wondered what makes paper strong and flexible? The answer lies in cellulose fibers, the primary building blocks of paper structure. These fibers come from plant cell walls and are long, strong, and flexible, giving paper its durability. During papermaking, cellulose fibers are broken down into pulp and then reassembled into sheets. Their natural hydrogen bonds create a network that provides strength and flexibility. The quality of these fibers directly impacts the paper’s texture, durability, and ability to hold ink. The more intact and aligned the cellulose fibers are, the stronger and more resilient the paper becomes. In fundamental terms, cellulose fibers form the backbone of your paper, defining its physical properties and overall performance.

Understanding Lignin and Its Impact on Paper Quality

Lignin provides rigidity and strength to plant fibers, but it can also affect paper quality over time. Its presence makes paper more prone to aging and yellowing, reducing durability. Understanding how lignin influences these factors helps you produce longer-lasting, higher-quality paper. Incorporating natural materials such as wood and linen can help mitigate some of these issues by promoting a more authentic and durable paper composition. Additionally, selecting appropriate processing techniques can further improve paper longevity and resistance to environmental effects.

Lignin’s Role in Strength

Understanding lignin is essential because it plays a crucial role in determining the strength and durability of paper. Lignin contributes through fiber reinforcement and lignin bonding, which help hold fibers together. When lignin bonds effectively, it enhances the paper’s structural integrity. However, too much lignin can weaken fibers over time, but in controlled amounts, it strengthens the overall matrix. The table below shows how lignin impacts paper strength:

| Aspect | Effect | Note |

|---|---|---|

| Fiber reinforcement | Increases overall toughness | Improves tensile strength |

| Lignin bonding | Enhances fiber adhesion | Boosts durability |

| Excess lignin | May cause brittleness | Needs careful control |

Additionally, the presence of lignin influences the paper’s resistance to environmental factors, which is important for paper longevity and quality.

Effects on Paper Aging

Ever wondered why some old books or documents fade and degrade over time? Lignin plays a significant role in this process because it’s less UV stable than cellulose. When exposed to sunlight, lignin absorbs UV rays, triggering oxidative degradation. This chemical reaction causes lignin to break down, producing acids that accelerate paper aging and discoloration. The presence of lignin can also contribute to the development of acidic conditions, which further hasten deterioration. These acids can also catalyze further chemical breakdown, leading to more rapid deterioration of the paper’s structure. Papers with high lignin content are more susceptible to fading, yellowing, and brittleness. The oxidative degradation process weakens the paper’s fibers, reducing durability and lifespan. Understanding the role of UV stability helps you appreciate why some papers age faster and guides choices for archival-quality materials. Additionally, advancements in AI security research are aiming to develop more resilient preservation methods for sensitive documents. To preserve documents longer, manufacturers often use lignin-free or low-lignin pulp, enhancing UV stability. Understanding lignin’s impact helps you appreciate why some papers age faster and guides choices for archival-quality materials.

Common Fillers and Their Functions in Paper

Have you ever wondered what gives paper its texture, strength, or whiteness? Fillers like koalin clay and calcium carbonate are added during manufacturing to improve these qualities. Koalin clay enhances smoothness and brightness, making the surface ideal for printing. Calcium carbonate boosts opacity and brightness while reducing costs. These fillers fill gaps between cellulose fibers, increasing density and durability. The table below shows some common fillers and their functions:

| Filler | Function | Benefits |

|---|---|---|

| Koalin Clay | Improves smoothness, brightness | Enhances surface quality |

| Calcium Carbonate | Increases opacity, whiteness | Reduces material costs |

| Titanium Dioxide | Brightens paper | Improves whiteness |

| Talc | Improves printability | Enhances surface finish |

Understanding how dream symbols relate to subconscious messages can also help in recognizing the underlying qualities of materials and processes involved in paper production. Recognizing the chemical composition of fillers is essential, as it impacts their performance and the overall quality of the paper. Moreover, the manufacturing process can influence how fillers interact with cellulose fibers, affecting final paper properties. Additionally, knowledge of regional resource availability can influence the choice of fillers used in different manufacturing locations. Being aware of environmental impact factors is also important when selecting fillers for sustainable production practices.

The Composition of Different Types of Paper

Different types of paper are composed with varying materials and manufacturing processes to suit their specific uses. You’ll find that fiber types play a pivotal role; for example, wood pulp provides strength, while cotton fibers offer a smooth, high-quality finish. Some papers incorporate recycled fibers to enhance environmental sustainability. Coating techniques also greatly influence the paper’s properties. Glossy papers for magazines use a layer of clay or polymer coatings to achieve brightness and smoothness, while uncoated papers like notebooks rely on natural fiber textures. By adjusting fiber types and coating methods, manufacturers tailor each paper’s durability, appearance, and performance. Understanding these variations helps you select the right paper for your needs, whether it’s for printing, packaging, or artistic purposes.

How Raw Materials Influence Paper Characteristics

Raw materials directly shape the properties of paper, influencing its strength, texture, and appearance. The way fibers align during processing affects how sturdy and flexible your paper feels. For example, aligned fibers create stronger, more uniform sheets, while random fiber arrangements can weaken the structure. Moisture content also plays a critical role; too much moisture can cause fibers to swell and affect bonding, leading to weaker or uneven surfaces. Proper moisture levels promote ideal fiber bonding and smoothness. Fiber alignment is essential for determining the final quality of the paper, as it impacts both durability and surface feel. Consider these factors: electric dirt bikes Raw material quality influences texture and appearance.

The Manufacturing Process and Material Selection

The manufacturing process and material selection play a vital role in shaping the final qualities of paper. You decide whether to use virgin fibers or incorporate recycled paper, which involves paper recycling methods. Chemical treatments are also essential—they improve strength, brightness, or printability, depending on the paper’s purpose. During production, fibers are processed, refined, and combined with fillers and additives to achieve desired properties. Additionally, understanding astrological signs can influence perceptions of attractiveness and confidence in personal presentation.

Innovations and Future Trends in Paper Composition

Innovations in paper composition are shaping a more sustainable future, with advances in eco-friendly materials taking center stage. Nano-enhanced technologies are improving paper strength and functionality, opening new possibilities for various applications. Additionally, biodegradable options are gaining popularity as industries seek environmentally responsible solutions. Understanding the odor of different substances can also inform better material choices and applications. It is also important to consider the safety of new materials, especially in products like home furnishings where consumer health is a priority. The contrast ratio of paper materials influences their visual clarity and overall quality in printed media, highlighting the importance of ongoing research in material properties. Incorporating antioxidants into paper products can further extend their durability and resistance to degradation over time. Furthermore, attention to personality traits in material design can lead to innovations that better meet consumer preferences and needs.

Sustainable Material Advances

Have recent advances in sustainable materials revolutionized how you approach paper composition? Absolutely. Innovations focus on utilizing renewable resources to reduce environmental impact and promote eco conscious manufacturing. Here are three key trends:

- Plant-based fibers: Researchers are replacing traditional wood pulp with fibers from agricultural waste like straw and bagasse, which are renewable resources.

- Biodegradable fillers: New fillers made from natural, compostable materials enhance paper quality while supporting sustainable disposal.

- Recycled content: Increased use of post-consumer waste minimizes reliance on virgin fibers and lowers the carbon footprint of paper production.

These advancements help create eco-friendly papers that align with sustainable practices, ensuring future manufacturing is both innovative and environmentally responsible.

Nano-Enhanced Paper Technologies

Recent breakthroughs in nanotechnology are transforming paper manufacturing by embedding nano-sized materials into traditional fibers. This process, called nanoparticle reinforcement, enhances paper’s strength, durability, and functional properties. By incorporating nanoparticles such as silica, graphene, or clay, manufacturers can produce papers with improved resistance to tearing and moisture. Surface modification techniques further optimize these materials, allowing for better bonding between nano-particles and fibers, which boosts overall performance. These innovations enable the creation of ultra-thin, lightweight, yet highly durable papers suited for specialized applications like electronics, packaging, and filtration. Additionally, understanding the fiber composition of paper helps in designing nano-enhanced materials that are both strong and environmentally friendly. The types of fillers used in paper production also influence how well nanoparticles can be integrated, affecting the final properties of the material. As research advances, nano-enhanced paper technologies promise to revolutionize the industry by offering stronger, smarter, and more versatile materials that meet evolving consumer and industrial needs.

Biodegradable and Eco-Friendly Options

How can paper manufacturing meet the growing demand for sustainability? By adopting biodegradable polymers and eco-friendly coatings, you can create greener options. These innovations lessen environmental impact and support recycling efforts. For example:

- Using biodegradable polymers in paper products ensures they break down naturally, minimizing waste.

- Applying eco-friendly coatings made from plant-based materials enhances durability without harming ecosystems.

- Developing compostable wraps and packaging options satisfies eco-conscious consumers while maintaining quality.

Future trends focus on integrating these materials seamlessly into production, making sustainable choices accessible and affordable. By embracing biodegradable and eco-friendly options, you help shift the industry toward a more sustainable future, reducing reliance on non-degradable plastics and harmful chemicals.

Frequently Asked Questions

How Does Moisture Content Affect Paper Longevity?

Moisture content critically impacts your paper’s longevity by influencing moisture regulation and aging resistance. When your paper absorbs excess moisture, it becomes vulnerable to mold, warping, and faster deterioration. Properly controlling humidity levels helps maintain ideal moisture content, enhancing aging resistance. By managing moisture effectively, you guarantee your paper stays durable longer, preventing premature aging and preserving its quality over time.

What Environmental Factors Influence Raw Material Quality?

You should consider environmental factors like sustainable sourcing and pollution control, as they directly influence raw material quality. Sustainable sourcing ensures your materials come from responsible sources, reducing contamination and variability. Pollution control measures prevent chemical impurities and pollutants from affecting raw material integrity. By focusing on these factors, you can improve consistency, strength, and overall quality, ultimately leading to better paper products and a more eco-friendly manufacturing process.

Are There Alternative Renewable Fillers for Eco-Friendly Paper?

Did you know that over 50% of paper production now explores eco-friendly options? You can consider biodegradable additives and plant-based fillers as sustainable alternatives for eco-friendly paper. These options reduce environmental impact by breaking down naturally and relying on renewable resources. Using plant-based fillers like hemp, rice husks, or bamboo not only promotes sustainability but also maintains paper quality, making your products more environmentally responsible and appealing to eco-conscious consumers.

How Do Different Manufacturing Techniques Impact Paper Strength?

Different manufacturing techniques markedly impact paper strength by influencing fiber bonding and additive effects. For instance, pressing and drying methods improve fiber bonding, resulting in stronger paper. Adding fillers or bonding agents enhances additive effects, increasing durability. You can optimize strength by adjusting these techniques, ensuring fibers bond tightly and additives work synergistically. Ultimately, selecting the right method affects the paper’s tensile strength, flexibility, and overall quality.

Can Paper Composition Be Customized for Specific Industrial Uses?

Imagine a world where your paper perfectly fits your needs—that’s what customization options can do. You can tailor paper compositions to meet industry-specific requirements, whether you need strength, flexibility, or durability. By adjusting cellulose, lignin, and fillers, you guarantee your paper performs exactly as needed. This precision customization opens endless possibilities, giving you the control to create specialized solutions for every industrial application.

Conclusion

As you explore paper’s composition, you’ll notice how each component—cellulose, lignin, and fillers—intertwines to shape its quality. Sometimes, it’s the smallest ingredient that makes the biggest difference, reminding you that even in complex processes, attention to detail matters. Ultimately, understanding these elements reveals that what seems insignificant can influence the final product, echoing the idea that the tiniest choices often lead to the most profound outcomes in both paper and life.