To make paper, you start with raw materials like wood pulp, recycled fibers, or alternative sources such as hemp. First, the wood is processed through pulping, where mechanical or chemical methods break it down into a fiber slurry. Next, this slurry moves through a paper-making machine, like the Fourdrinier, which forms and dries it into sheets. High-pressure rollers press the sheets to remove excess water, and drying cylinders finalize their moisture content. Today's practices often include recycling to lower environmental impact. If you're curious about the innovations and environmental practices shaping this industry, there's much more to explore!

Key Takeaways

- Paper is made from raw materials like wood pulp, recycled paper, and alternative fibers, which are processed into a fiber slurry.

- The pulping process can be mechanical or chemical, affecting the paper's quality and production cost.

- The Fourdrinier machine forms paper through wet pressing, drying, and coating, enhancing strength and surface properties.

- Sustainable practices, including recycling and responsible forestry, are essential for reducing environmental impact during paper production.

- Future trends in paper manufacturing focus on digital transformation and biodegradable products to meet eco-friendly consumer demands.

Overview of Paper Production

When you think about how paper is made, it's fascinating to realize that it all starts with raw materials like wood, recycled paper, and alternative fibers.

The journey of paper production involves several key processes that transform these materials into the final product. It begins with the pulping processes, where raw materials are broken down into fibers, creating a slurry. This mixture is then fed into a paper making machine, where it undergoes various stages to achieve the desired thickness and quality.

Once the fibers are prepared, the wet end of the machine forms the paper sheet. It's then pressed in the wet press section, where excess water is removed. After that, the dryer section helps further reduce moisture content, ensuring the paper is dry and ready for the next phase.

Finally, the calender smooths and finishes the paper, giving it the necessary characteristics for its intended use.

With the global paper production capacity reaching around 400 million metric tons annually, the industry continually adapts to consumer demands and environmental standards, focusing on innovative techniques that enhance efficiency and sustainability in paper production.

Raw Materials Used

The process of making paper relies heavily on specific raw materials that provide the necessary fibers. The primary source of these fibers is wood pulp, derived from trees like spruce, pine, fir, eucalyptus, and birch. These trees are chosen for their fiber quality and availability, guaranteeing a consistent supply for paper production.

In addition to wood pulp, you'll find that recycled fibers play a significant role in manufacturing. By incorporating both pre-consumer and post-consumer waste, you help promote sustainability and reduce the environmental impact of paper production.

Cotton and linen fibers are also important, especially in specialty papers and corporate stationery, where their strength and unique feel are prized. Alternative natural fibers like hemp and mulberry can be utilized for specific types of paper as well, adding diversity to the market.

To maintain a long-term supply of these raw materials, sustainable forestry practices are vital. By emphasizing responsible sourcing, you contribute to mitigating deforestation and environmental degradation, making your paper production more environmentally friendly.

Pulping Process Methods

In paper production, the pulping process is essential for separating cellulose fibers from lignin and other components found in logs.

You've got two main methods to choose from: mechanical pulping and chemical pulping.

Mechanical pulping involves grinding logs to extract wood fibers. While this method retains lignin, resulting in lower quality paper, it's energy-intensive and often used for cost-effective products like newsprint.

You'll notice that papers produced this way tend to be thicker and less durable.

On the other hand, chemical pulping employs chemicals to dissolve lignin while preserving the integrity of cellulose fibers. A common technique is the Kraft process, where wood chips are treated with hot water and chemicals under pressure.

This process yields brighter and stronger paper products, making it the preferred choice for high-quality applications.

The choice of pulping method profoundly impacts the final paper quality. If you want higher strength and brightness, chemical pulping is the way to go.

However, if cost is a concern, mechanical pulping can still deliver satisfactory results for certain uses.

Understanding these methods helps you appreciate the nuances of paper production.

Mechanical Pulping Explained

Efficiency defines mechanical pulping, a method that harnesses the power of grinding logs to separate cellulose fibers from lignin without chemical intervention. This technique primarily produces mechanical pulps, which retain more lignin, giving the resulting paper a grey-yellow color.

You'll notice that while this process generates a high energy consumption rate due to the significant mechanical force required, it also results in minimal waste.

Groundwood pulp, a common output of mechanical pulping, is often used for lower-quality papers, such as newsprint and magazines. Its cost-effectiveness makes it an attractive choice, especially during times of high demand for printing materials.

However, keep in mind that the fibers produced are shorter and less refined than those from chemical pulping. This can affect the brightness and strength of the paper, making it less suitable for high-end products.

Historically, mechanical pulping was developed to address paper shortages, allowing for efficient production at lower costs.

Chemical Pulping Overview

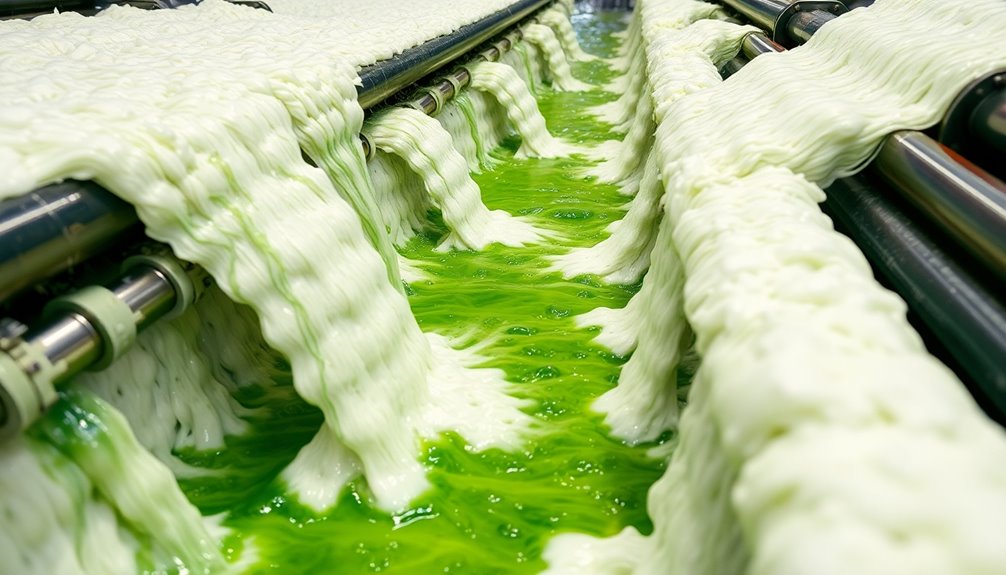

In chemical pulping, you break down wood chips into cellulose fibers using heat and chemicals, which effectively separates the fibers.

This process not only produces stronger, brighter pulp but also generates black liquor, a by-product that can be repurposed for energy or chemicals.

As we explore the advantages and environmental impacts of chemical pulping, you'll see how this method stands out in producing premium paper products.

Chemical Pulping Process

Chemical pulping transforms wood into high-quality paper through a series of precise steps. First, you cut wood logs into small chips, which are then subjected to a chemical treatment involving hot water and specific chemicals. This process breaks down the lignin that binds cellulose fibers together, allowing you to extract purer fibers.

Typically, this operation occurs under high pressure and temperature, generating a byproduct known as black liquor. This black liquor contains dissolved lignin and various chemicals used during the pulping process.

The main types of chemical pulping processes are the Kraft process and the sulfite process. Among these, the Kraft process is favored for its ability to produce stronger and brighter pulp, making it the most widely used method in the industry.

Developed in the 19th century, the Kraft process also enables the recycling of chemicals. You can recover these chemicals from black liquor through evaporation and combustion.

Ultimately, chemical pulping results in higher quality paper compared to mechanical pulping, as it yields cleaner cellulose fibers with minimal lignin content, leading to a brighter paper product ready for various applications.

Advantages of Chemical Pulp

When it comes to producing high-quality paper, the advantages of chemical pulp stand out notably. One of the key benefits is its strength; chemical pulp, particularly from the Kraft method, effectively dissolves lignin, resulting in a pulp that's considerably stronger than what mechanical methods produce. This strength translates into durability, making it ideal for a wide range of paper products.

Another advantage is the high yield of usable fiber. With over 90% of wood converted into pulp, you're left with minimal waste, which is a considerable improvement over mechanical processes that often leave behind substantial remnants.

Additionally, the bleaching process associated with chemical pulping enhances the brightness of paper grades, improving the aesthetic appeal and printability of the final product.

Lastly, chemical pulping allows you to utilize a broader range of raw materials, including wood chips and sawmill residues. This flexibility contributes to more sustainable practices within the paper industry, making chemical pulp a smart choice for producing high-quality paper.

#

Environmental Impact

Considerations

The environmental impact of chemical pulping is an essential factor to evaluate in modern paper production. While the Kraft process excels in preserving cellulose fibers and producing stronger pulp, it does come with significant resource demands.

You'll notice that chemical pulping typically requires large amounts of water and energy. However, many modern facilities are adopting closed-loop systems to minimize water usage and lessen the overall environmental impact.

Another consideration is the by-product known as black liquor, which contains lignin and chemicals. This by-product can be recovered and used as a fuel source, enhancing energy efficiency within pulp mills.

On the other hand, the use of chlorine and chlorine compounds in bleaching processes has raised serious environmental concerns. Fortunately, the industry is shifting toward chlorine-free bleaching alternatives, which are less harmful.

Paper Manufacturing Techniques

Now that you understand chemical pulping, let's explore the key paper manufacturing techniques.

You'll see how the Fourdrinier machine process sets the stage for pressing and drying, followed by coating and finishing.

Each step is essential in creating the high-quality paper you use every day.

Fourdrinier Machine Process

Although many techniques exist for making paper, the Fourdrinier machine stands out for its efficiency and continuous production capabilities. This innovative machine consists of four main sections: the wet end, wet press, drying section, and calender section.

At the wet end, you'll see a mixture of pulp and water deposited onto a moving wire mesh. Here, water is drained away, forming a wet paper sheet.

Next, the sheet moves into the wet press section, where high-pressure rollers compact the fiber structure further and reduce water content to about 45-55%. This step is essential for preparing the sheet for drying.

After that, the sheet enters the drying section, where steam-heated cylinders evaporate the remaining moisture, achieving a final water content of around 6%. This process guarantees that the paper is ready for further processing.

Finally, the calender section applies pressure through rollers to smooth and finish the paper surface. Here, you can make adjustments to achieve the desired gloss and thickness, resulting in a high-quality product.

The Fourdrinier machine efficiently transforms pulp into paper, highlighting its significance in the paper manufacturing process.

Pressing and Drying

After leaving the calender section, the paper web undergoes pressing and drying, two crucial stages that enhance its quality.

During the pressing stage, the paper web passes through high-pressure nip rollers that considerably reduce its water content to around 45-55%. This process compresses the fibers, forming a dense sheet that's necessary for strength and smoothness. Effective pressing intertwines the fibers, which improves the overall texture of the paper.

Next comes the drying phase, where the paper web travels through steam-heated cylinders operating at about 130°C. This helps evaporate moisture, achieving a final dryness level of 80-85%. To boost the paper's stiffness and bonding properties, a wet sizing solution containing starch is applied during this stage.

Once pressing and drying are complete, the paper travels approximately 400 meters through smooth rollers, ensuring a glossy surface that's ideal for printing.

These steps are crucial in transforming the raw paper web into a high-quality product ready for various applications, ensuring it meets the demands of consumers and industries alike.

Coating and Finishing Techniques

Coating techniques considerably enhance the surface properties of paper, making it smoother, brighter, and more suitable for printing. You'll find that common coating materials like clay, latex, and calcium carbonate are used to create a smooth and glossy finish on various paper grades.

During the coating process, a wet mixture is applied to the paper sheet, followed by a drying phase that guarantees a uniform layer.

Once coated, finishing techniques, such as calendering, come into play. This process involves passing the coated paper through heated rollers, which refine the surface further, increasing both gloss and smoothness.

If you're working with specialty papers, you might encounter additional finishing processes designed to achieve unique textures or properties. These variations cater to specific uses in packaging, printing, or artistic applications.

Ultimately, understanding these coating and finishing techniques is essential for anyone involved in paper manufacturing. They not only improve the final product but also enhance its performance in various applications.

Paper Machine Sections

The paper machine is a complex system made up of several key sections that work together to produce high-quality paper.

First, you'll find the forming section, where a continuous wire mesh removes water from the paper stock. This process creates a wet fiber web, vital for the initial sheet formation.

Next, the wet paper moves into the press section, which utilizes high-pressure rolls to extract even more excess water. This significant reduction in moisture content prepares the sheet for the drying phase.

After the press section, the paper enters the dryer section. Here, it passes around steam-heated cylinders that further decrease its water content to about 6%. This important step guarantees proper drying, making the paper ready for subsequent processing.

The final section is the calender section, where the dried paper gets smoothed and finished under pressure. This allows for adjustments to achieve the desired surface quality and glossiness.

Each of these sections plays an integral role in transforming raw materials into the high-quality paper you're familiar with, ensuring that every sheet meets the necessary standards for various applications.

Pressing and Drying Processes

In the pressing and drying processes of paper production, the paper web moves through nip rollers that efficiently reduce its water content to 45-55%, while simultaneously compressing the fibers to form a dense sheet.

This pressing process is the second most efficient de-watering method, with granite press rolls commonly utilized to enhance water removal from the paper stock.

Once the pressing is complete, the paper enters the drying section. Here, it travels through steam-heated cylinders maintained at temperatures around 130°C. This step achieves a final moisture content of 80-85%.

It's essential for guaranteeing that the paper is dry enough for further processing and ideal quality.

During the drying process, a wet sizing solution, typically containing starch, is applied to improve the paper's stiffness and bonding strength.

After passing through the drying cylinders, the paper continues on an extensive journey of about 400 meters. This long distance guarantees thorough drying and smoothness, ultimately preparing the paper for high-quality printing.

## Environmental Impact

As you explore the intricate processes involved in paper production, it's important to contemplate the environmental impact of these practices.

The industry faces considerable challenges, including deforestation and habitat loss. To combat these issues, adopting sustainable forestry practices is vital. Certification programs like the Forest Stewardship Council (FSC) help guarantee responsible forest management, greatly reducing the environmental footprint of paper production.

Consider these points:

- Recycling paper lowers energy consumption and greenhouse gas emissions.

- It plays a key role in fostering a circular economy.

- Increased consumer demand for sustainable products drives industry innovation.

Innovations in Papermaking

As you explore innovations in papermaking, you'll notice how technological advancements have transformed machinery and production methods.

These improvements not only increase efficiency but also emphasize sustainable practices that benefit the environment.

Technological Advancements in Machinery

Papermaking has undergone remarkable transformations thanks to technological advancements in machinery. Modern paper-making machines have considerably improved efficiency and output. The invention of the Fourdrinier machine in the early 19th century allowed for continuous production through a moving screen belt, revolutionizing manufacturing paper.

Here are some key innovations that have shaped the industry:

- Mechanization of pressing and drying stages, utilizing high-pressure nip rollers and steam-heated drying cylinders, which enhances water removal efficiency.

- The introduction of synthetic felts and advanced control systems, resulting in smoother, denser paper sheets.

- Development of twin wire machines that improve drainage and uniformity, contributing to higher quality paper with better physical properties.

Additionally, continuous improvements in pulping processes, like adopting the Kraft process, have considerably boosted the strength and brightness of paper products.

These technological innovations not only streamline operations but also elevate the quality of the final product. By embracing these advancements, you're engaging with a process that's more efficient and sustainable, ensuring that your paper meets the demands of today's consumers.

Sustainable Practices in Production

Advancements in machinery have paved the way for sustainable practices in papermaking, making the industry more environmentally friendly. You'll find that many manufacturers now use recycled fibers, with up to 70% of paper production incorporating recycled content. This shift greatly reduces the environmental impact of paper production.

Innovative approaches include certification programs like the Forest Stewardship Council (FSC), which guarantees responsible forest management. Additionally, new pulping processes, such as enzymatic treatments, minimize chemical use and energy consumption while improving paper quality. Closed-loop systems are also gaining traction, enabling the reuse of water and chemicals, thereby cutting down waste.

Here's a quick overview of these sustainable practices:

| Practice | Description | Benefit |

|---|---|---|

| Recycled Fibers | Incorporating recycled content in production | Reduces raw material usage |

| FSC Certification | Promotes responsible forest management | Supports biodiversity |

| Enzymatic Pulping | Reduces chemical use and energy consumption | Enhances final product quality |

| Closed-Loop Systems | Reuses water and chemicals in production | Minimizes waste |

| Life Cycle Assessments (LCA) | Evaluates environmental impact throughout production | Guides sustainability improvements |

These innovations lead to a more sustainable papermaking process.

Frequently Asked Questions

How Is Paper Made Step by Step?

To understand how paper's made step by step, you start with raw materials, usually wood.

First, you pulp it to separate cellulose fibers from lignin.

Next, you mix the fibers with water to create a slurry, which spreads onto a wire mesh to form a sheet.

As it moves, excess water's removed.

The sheet then goes through rollers to extract more moisture, and finally, it's dried and finished for use.

Is Paper Still Made From Trees?

Yes, paper's still primarily made from trees. You might be surprised to learn that nearly 90% of global paper production comes from wood pulp.

Common sources include spruce, pine, and eucalyptus. While there's a push for recycled materials, the demand for tree-derived pulp remains high because it's cost-effective and provides quality.

Sustainable forestry practices are essential to guarantee that you can keep enjoying paper products without depleting resources.

How Is Paper Made From Trees?

To make paper from trees, you start by harvesting logs from species like spruce or pine.

After debarking and cutting the logs into chips, you use mechanical or chemical pulping to separate cellulose fibers from lignin.

Chemical pulping involves treating the chips with heat and chemicals, creating a smoother pulp.

You then blend this pulp with water, form it into sheets, and dry it to produce the finished paper ready for use.

What Exactly Is Paper Made Of?

When you think about what paper's made of, you'll find it's primarily cellulose, sourced from wood pulp. This usually comes from trees like spruce, pine, and eucalyptus, but it can also include recycled paper for sustainability.

Specialty papers may use cotton or hemp fibers, prized for their strength. The type of raw materials you choose impacts the paper's texture and thickness, making it essential to select wisely for your specific needs.

Conclusion

In summary, understanding how paper's made reveals the intricate processes and materials involved. From the raw materials to the pulping methods, each step plays an essential role in creating the final product you use every day. While the industry faces environmental challenges, innovations are paving the way for more sustainable practices. By being aware of this journey, you can appreciate the paper you interact with and support efforts to make papermaking more eco-friendly.