To cut corrugated sheets cleanly, use a sharp utility knife for small sections by scoring multiple times along your marked line before snapping it. For larger sheets, opt for a circular saw or jigsaw with a blade suitable for metal or plastic coating, setting the depth just deeper than the sheet’s thickness. Always wear protective gear, work on a stable surface, and maintain steady pressure for smooth results. Keep exploring for more expert tips and techniques.

Key Takeaways

- Score the sheet multiple times with a utility knife along the marked line for a clean break.

- Use a circular saw or jigsaw with appropriate blades for larger or thicker sheets.

- Set the power tool blade depth slightly deeper than the sheet’s thickness to avoid chipping.

- Ensure the sheet is securely clamped and supported to maintain stability during cutting.

- Smooth rough edges with a file or grinder post-cut to achieve a clean, professional finish.

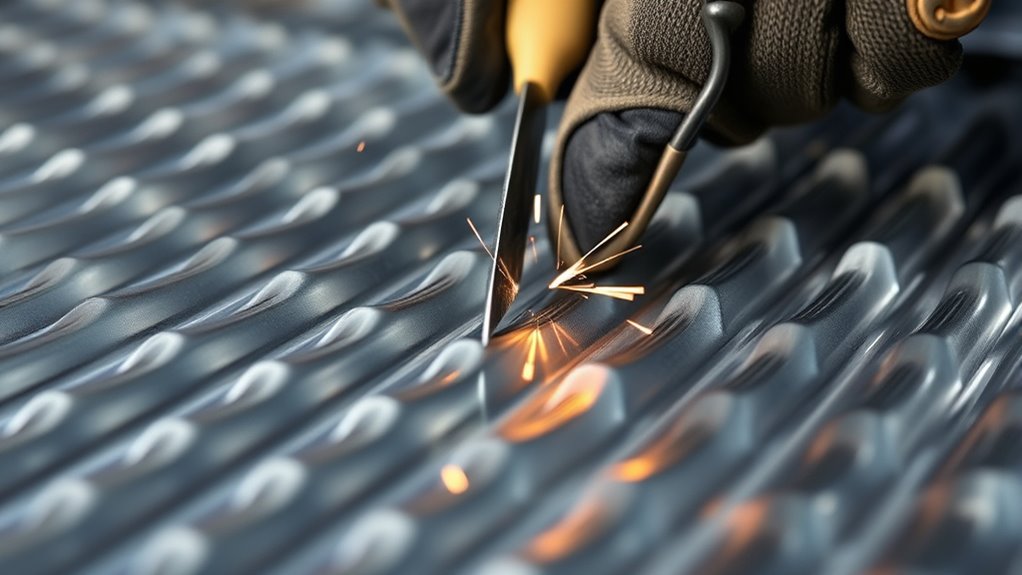

Have you ever wondered how to cut corrugated sheets accurately and efficiently? When tackling this task, understanding the significance of safety precautions and tool selection is essential. Cutting corrugated sheets can be straightforward, but only if you approach it with the right mindset and the proper equipment. First, safety precautions should be your top priority. Always wear protective gear such as safety glasses, gloves, and ear protection, especially if you’re using power tools. Corrugated sheets can have sharp edges and may produce flying debris or dust, so safeguarding yourself minimizes injury risk. Working in a well-ventilated area also helps keep dust and fumes away from your breathing zone, guaranteeing a safer workspace. Secure the sheet firmly on a stable surface, using clamps if necessary, to prevent slipping or shifting during cutting. This not only keeps you safe but also ensures cleaner, more precise cuts. Proper exfoliation of the material before cutting can also help achieve smoother edges and prevent tearing. Choosing the right tools is vital for a clean and efficient cut. For small or delicate cuts, a high-quality utility knife with a sharp blade can do the job. Score along the desired line multiple times, applying consistent pressure, until the sheet weakens enough to snap cleanly. For larger or thicker sheets, power tools like a circular saw with a fine-toothed blade or a jigsaw fitted with a metal-cutting blade are your best options. Make sure to select a blade appropriate for the material—metal or plastic-coated corrugated sheets require specific blades to prevent chipping or rough edges. Always check your tools for sharpness and proper functioning before starting, as dull or damaged blades can cause uneven cuts and increase the risk of accidents. Before making any cuts, measure and mark your line clearly with a marker or chalk, ensuring accuracy. When using power tools, set the blade depth just slightly deeper than the thickness of the sheet to avoid unnecessary splintering or damage. Keep a steady hand and push the tool smoothly through the material, maintaining consistent pressure without forcing it. If you’re working with larger sheets, consider cutting in sections rather than trying to handle the entire sheet at once—this reduces strain and improves precision. After cutting, inspect the edges and smooth any rough spots with a file or grinder if needed. Remember, patience and proper technique are key to achieving clean, professional-looking cuts. By combining safety precautions with careful tool selection, you’ll make your project safer, easier, and more successful.

Frequently Asked Questions

What Safety Gear Is Recommended When Cutting Corrugated Sheets?

When cutting corrugated sheets, you should wear protective gloves to prevent cuts and eye protection to shield your eyes from flying debris. Safety goggles or glasses are essential, especially when using power tools, to avoid injury from shards or dust. Additionally, consider wearing a dust mask if dust becomes airborne. Always prioritize safety by using the right gear to keep yourself protected throughout the cutting process.

Can I Cut Corrugated Sheets With a Utility Knife?

You can use a utility knife to cut corrugated sheets, but it’s like trying to carve a mountain with a spoon—limited and often frustrating. Utility knife limitations include uneven cuts and difficulty penetrating thick or tough material. For cleaner, straighter edges, consider alternative cutting tools like a circular saw or a fine-tooth saw, which make the job easier and results more professional. Relying solely on a utility knife may leave you with jagged, imprecise edges.

How Do I Prevent Jagged Edges During Cutting?

To prevent jagged edges, focus on proper edge finishing and cutting techniques. Use a sharp utility knife or a fine-tooth saw and make slow, steady cuts to guarantee smooth edges. Keep your blade aligned and apply consistent pressure. After cutting, you can sand or file the edges lightly to refine the finish. Practicing these steps helps achieve clean, professional-looking edges with minimal jaggedness.

What Is the Best Way to Store Leftover Sheets?

To store leftover corrugated sheets, use sturdy storage solutions like vertical racks or flat storage in a dry, cool space to prevent warping or damage. Keep sheets flat or upright, secured with straps or braces for leftover management. Label each sheet for easy identification. Proper storage guarantees your sheets remain in good condition, ready for future use, saving you time and money while maintaining their quality.

Are There Specific Blades for Different Types of Corrugated Materials?

Think of blades as keys to different doors; each one opens a specific type of corrugated material. You’ll want to choose blade compatibility based on the material’s flexibility. For softer, more flexible sheets, a fine-tooth blade works best, while rigid or thick materials need a sturdier, industrial blade. Always match the blade to the material to guarantee clean cuts and avoid damaging your sheets.

Conclusion

Now that you know how to cut corrugated sheets carefully and cleanly, you can confidently conquer your projects. With clever cuts and consistent control, you’ll create crisp, clean edges every time. Don’t let doubts dampen your determination—deliberate, deliberate, and daring, you’ll deliver durable results. Embrace the ease of expert techniques, and enjoy the excellence of your craftsmanship. Keep cutting confidently, and watch your work turn out perfect, polished, and professional every single time.