PVC film's main ingredient is polyvinyl chloride, a highly durable thermoplastic. This core component gets enhanced with various additives like plasticizers, stabilizers, and fillers, which improve its flexibility and overall performance. Depending on its intended use, colorants and other materials can be added to create either rigid or flexible films. Methods like calendering and casting are used during production to achieve different qualities in the films, such as clarity and toughness. Understanding these elements helps you see why PVC film is so versatile and widely used across various industries. There's much more to explore about its applications and benefits.

Key Takeaways

- PVC film is primarily composed of polyvinyl chloride (PVC), a versatile and durable thermoplastic polymer.

- Additives such as plasticizers, stabilizers, and fillers enhance the film's flexibility and durability.

- Colorants and other performance-enhancing additives are included for specific application requirements.

- The production methods for PVC film include calendering and casting, influencing its final properties.

- PVC film can be either rigid or flexible, depending on the formulation and processing techniques used.

practicalWs White/Gray Marble Contact Paper 17.7 inch x 78.7 inch, Marble Peel and Stick Wallpaper with Tools, Self Adhesive Vinyl Film Contact Paper for Countertops

Combination kit: peel and stick wallpaper in a kit design, including squeegee (soft squeegee will not damage the…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Overview of PVC Film

PVC film is primarily made of polyvinyl chloride (PVC), a highly versatile thermoplastic known for its impressive durability and chemical resistance. This material comes in various forms, including rigid PVC film, which you might encounter in numerous applications across different industries.

The production methods, such as calendering and casting, allow manufacturers to create PVC film in multiple thicknesses and finishes tailored to specific needs.

When you use PVC film, you're benefiting from its outstanding properties. Additives like heat stabilizers and plasticizers are often mixed into the PVC during manufacturing to enhance flexibility, impact resistance, and aging stability.

The film is available in gauges ranging from 0.003 to 0.030 inches, making it suitable for everything from packaging to graphics and construction projects.

Another significant advantage is its recyclability, which supports sustainability efforts. You can trust that PVC film not only performs well but also contributes to reducing waste over time.

AHANDMAKER 20 Pcs Clear PVC Flexible Plastic Board Sheet, 8.25 x 11.75 inch Clear Plastic Sheet with Protective Paper for Craft, Windows, Picture Frames, DIY Display Projects

Reliable Material: This product is made of high-quality Polyvinyl Chloride plastic, with good safety and flexibility, very safe…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Composition of PVC Film

PVC film is mainly made from polyvinyl chloride (PVC), a tough and flexible polymer.

To enhance its properties, manufacturers add plasticizers, stabilizers, and fillers, which improve flexibility and durability.

Additionally, you might find colorants and other additives that boost the film's performance in specific applications.

Raw Material Components

The composition of PVC film showcases a fascinating interplay of materials that contribute to its versatility and functionality. At its core, you'll find polyvinyl chloride (PVC), a synthetic thermoplastic polymer formed from the polymerization of vinyl chloride monomers. This primary component is what gives PVC film its unique properties.

To enhance its performance, several raw materials are blended into the PVC formulation, including:

- Plasticizers: These are essential for making the film flexible and workable. Phthalate plasticizers are commonly used, though alternatives are being explored due to health concerns.

- Heat Stabilizers: These additives improve the thermal resistance of the film, ensuring it withstands various environmental conditions.

- Fillers: These materials can enhance the film's mechanical properties and reduce production costs.

- Pigments: They contribute to the film's color, allowing for a range of aesthetic options.

The combination of these elements allows for variations that create either rigid or flexible PVC films, tailored to meet specific industry needs.

Understanding these raw material components is vital for appreciating the complexities behind PVC film production.

Additives and Enhancements

Over time, additives and enhancements play an essential role in optimizing the performance and functionality of PVC film. These components help guarantee that the film meets various application requirements while maintaining durability and flexibility.

Here's a quick overview of some common additives used in flexible PVC film:

| Additive Type | Purpose |

|---|---|

| Heat Stabilizers | Prevent degradation from heat and UV exposure |

| Phthalate Plasticizers | Increase flexibility and softness |

| Fillers | Improve opacity and reduce production costs |

| Colorants | Enhance color vibrancy and aesthetic appeal |

| Auxiliary Agents | Enhance processing characteristics |

While phthalate plasticizers contribute to the film's flexibility, they raise concerns about potential health effects, prompting the industry to explore safer alternatives. Other additives, like heat stabilizers, guarantee that your PVC film withstands environmental challenges. By incorporating these various additives, you can achieve a product that not only meets your needs but also adheres to safety standards. Balancing performance and health considerations is key when selecting additives for your flexible PVC film.

tesa 4970 Double-Sided PVC Film Tape, White, 1 in x 60 yd, 1 Roll

SPECIFICATIONS: This white, double-sided mounting tape measures 8.9 mils thick, 1 inch wide, and 180 feet long. The…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Production Methods

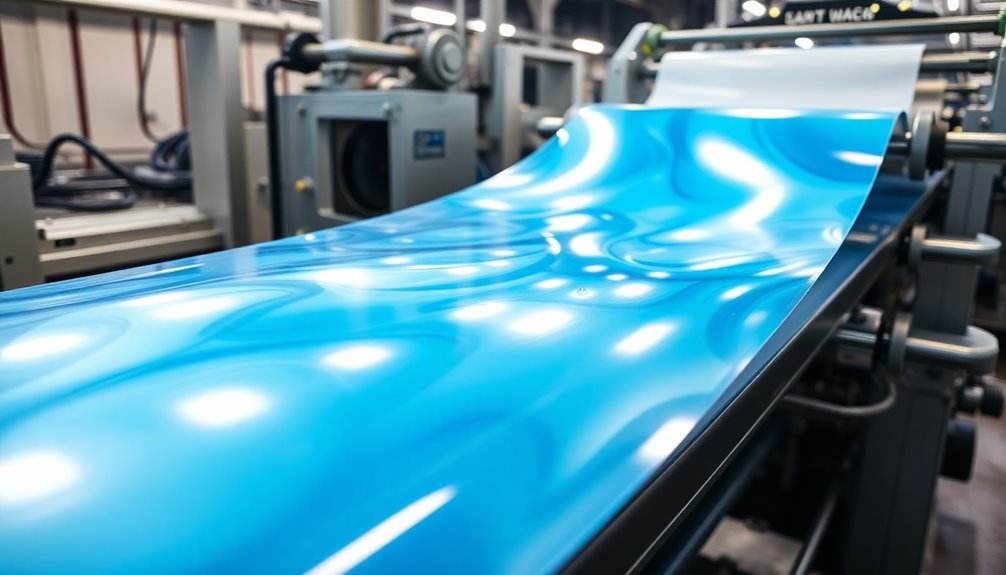

When it comes to producing PVC film, two main techniques stand out: calendering and cast film production.

In the calendered process, you flatten a PVC mixture into film using heated rolls, while cast film techniques involve blending PVC with additives to achieve different properties.

Each method offers unique advantages, making them suitable for various applications in the market.

Calendered Production Process

Calendered production is a key method for creating high-quality PVC film. In this process, you mix polyvinyl chloride (PVC) powder with a liquid softener. Then, you pass the mixture through heated counter-rotating rolls operating at approximately 350°F. This creates a homogeneous film with enhanced properties.

Here's what happens during the calendered production process:

- The PVC melt is flattened under pressure in the roll gap.

- Lower molecular weight resins and organopolysiloxane are utilized to enhance gloss.

- The method allows for producing PVC films in various thicknesses, typically from .003 to .030 inches.

- The resulting calendered PVC film boasts superior clarity, making it ideal for visually appealing applications.

You'll find that calendered PVC is widely used in graphic arts, packaging, and crafting. Its excellent dimensional stability and ease of die-cutting make it perfect for precise applications.

Cast Film Techniques

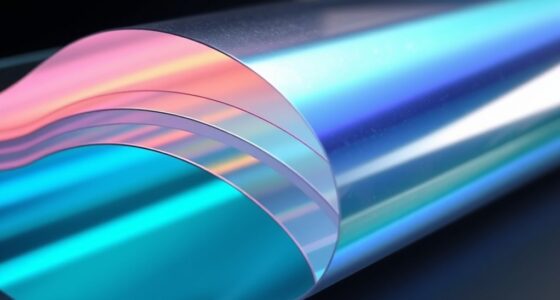

After exploring the calendered production process, it's time to look at another important method: cast film techniques. This process involves mixing PVC resin with plasticizers and stabilizers, resulting in a flexible and versatile film suitable for various applications.

Depending on the specific formulation and processing conditions, you can produce both flexible and rigid PVC films.

In the casting process, the PVC mixture is poured into a mold or onto a moving surface. It's then heated, which allows it to solidify into a uniform, thin sheet. One of the standout features of cast film techniques is their ability to produce films with excellent clarity and surface finish. This quality makes them ideal for applications that require high visual appeal.

Additionally, cast films can be further processed through thermoforming, enabling you to shape and mold them into more complex structures tailored for specific industrial needs.

Whether you're looking for flexible or rigid film, understanding these techniques enhances your capability to choose the right PVC film for your projects.

Durable Packaging – PVC1220 PVC Film Roll, 12" Width x 2000' Length

Durable PVC film roll

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Additives Used

Many people mightn't realize that additives play a crucial role in the performance and versatility of PVC film. These substances enhance the properties of the film, making it suitable for a wide range of applications.

Here are four key additives commonly used in PVC film:

- Phthalate Plasticizers: These are added to improve flexibility and softness. Depending on your product's requirements, you might use either high or low molecular weight phthalates, considering their varying levels of toxicity.

- Heat Stabilizers: Essential for enhancing resistance to heat aging and weathering, these additives guarantee that your PVC film maintains its performance over time, especially in challenging environments.

- Colorants: By incorporating colorants, you can achieve specific pigmentation, allowing for aesthetic customization in your products.

- UV Stabilizers: These protect the film from sun damage, ensuring longevity and durability when exposed to outdoor conditions.

Incorporating these additives during the compounding process tailors PVC film to meet specific needs, improving its impact resistance and transparency.

Properties of PVC Film

PVC film boasts a range of impressive properties that make it a go-to material for various applications. Made from polyvinyl chloride, this durable thermoplastic exhibits remarkable physical properties, including high resistance to chemicals, abrasion, and impact. These features guarantee it performs well in long-term uses, giving you peace of mind.

One of the standout characteristics of PVC film is its excellent dimensional stability. It maintains its shape and prevents warping across a wide temperature range, which is essential for numerous applications.

You'll also appreciate that PVC film is non-toxic and complies with safety standards set by the FDA, CPSC, and NSF, making it safe for food packaging and children's products.

Additionally, PVC film is fire-resistant due to its high chlorine content, allowing it to be self-extinguishing and emit fewer harmful chemicals when burned. This trait enhances safety in sectors like construction and automotive.

Its versatility makes it easy to manipulate and shape, so it's perfect for custom applications across industries such as graphic arts, medical, and transportation. With these properties, PVC film stands out as a reliable choice for various needs.

Applications of PVC Film

Thanks to its impressive properties, PVC film finds a multitude of applications across various industries. You'll see PVC film used in construction, automotive, healthcare, packaging, and retail, showcasing its versatility as an essential plastic material.

Here are four key applications:

- Construction: PVC film is widely used for doors, windows, and furniture due to its durability and resistance to moisture and abrasion.

- Automotive: In the automotive industry, it serves as insulation and protective covers for components, enhancing both safety and aesthetic appeal.

- Healthcare: PVC film is important in healthcare, providing secure packaging for medical products like blood bags. Its non-toxic and durable properties make it a safe choice.

- Packaging: The packaging industry benefits from PVC film's flexibility, making it ideal for tamper-resistant seals and clamshell packaging solutions.

In retail, you'll also find PVC film used for point-of-purchase displays and promotional materials. Its clear visual appeal and high impact resistance make it an attractive choice for grabbing customer attention.

With so many industrial applications, PVC film continues to prove its worth across diverse sectors.

Environmental Considerations

When considering the environmental impact of PVC film, it's essential to recognize its non-toxic nature and low emissions during use. This means you can feel confident that PVC film won't pose health risks under normal conditions.

Its production adheres to strict environmental regulations, guaranteeing safety across various industries.

One of the most significant aspects of PVC film is its recyclability. By promoting a circular economy, PVC helps reduce waste in landfills, contributing to sustainability efforts.

When you choose products made from PVC, you're supporting a material that can be repurposed rather than simply discarded.

Additionally, PVC's long lifespan means you won't need to replace it frequently, further minimizing waste and resource consumption over time.

Proper manufacturing and usage practices guarantee that PVC emits low levels of harmful substances, which helps maintain environmental safety.

Economic Benefits

Cost-effectiveness stands out as a key advantage of PVC film, making it an appealing choice for both manufacturers and consumers. Its economic value is evident in several ways:

- Low Initial Cost: PVC film provides a low-price solution for various applications, ensuring that you get quality without breaking the bank.

- Long-term Savings: The durability of PVC film reduces the need for frequent replacements, which can save your business money over time.

- Recyclability: PVC film's recyclability contributes to reduced waste and lower disposal costs, enhancing its economic value in sustainable practices.

- Versatility: With its ability to be used across multiple sectors, PVC film increases market demand and drives down production costs due to economies of scale.

Additionally, the low maintenance requirements of PVC film help you save on operational expenses while maintaining aesthetic appeal and functionality.

Whether you're utilizing it for home decor or protective coverings, PVC film's combination of affordability and durability makes it a smart investment for anyone looking to optimize their resources.

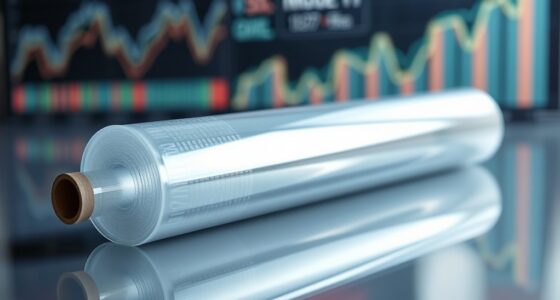

Market Trends

The rising demand for PVC film across various sectors showcases its growing importance in today's market. This increase is particularly notable in the packaging and construction industries, where its versatility and cost-effectiveness make it a preferred choice.

As you explore the latest market trends, you'll notice that innovations in manufacturing techniques are greatly enhancing the properties of PVC film, resulting in better performance and expanded applications.

Competitive pricing compared to alternative materials is another factor driving PVC film's market share. Businesses are increasingly drawn to PVC film not only for its affordability but also for its ability to meet diverse needs.

Additionally, there's a notable trend towards customization in PVC film production. Industries are seeking tailored solutions that cater to specific requirements, further propelling the demand.

Regions like Asia-Pacific and North America are experiencing rapid market expansion, reflecting a broader acceptance and application of PVC film.

As you navigate these trends, it's clear that PVC film is carving out a prominent place in the market, making it an essential material for various applications in the years to come.

Frequently Asked Questions

What Is the Composition of PVC Film?

When you look at the composition of PVC film, you'll find it's primarily made from polyvinyl chloride resin.

This resin often includes additives like heat stabilizers for durability and plasticizers to enhance flexibility. In fact, about 20% or more of the film can be plasticizers, which help maintain its structural integrity while making it soft and workable.

Manufacturers can customize these formulations to suit various applications, like food packaging or medical uses.

Is PVC Film Food Safe?

Yes, PVC film is food safe. It complies with FDA standards, so you don't have to worry about harmful substances leaching into your food.

Its non-toxic nature makes it ideal for packaging, like clamshell containers and shrink wraps. Plus, manufacturers can create it without harmful additives, ensuring your food stays protected.

The film's durability and moisture resistance also help extend the shelf life of your food items. Enjoy your meals with peace of mind!

What Is PVC Coating Made Of?

PVC coating's made of polyvinyl chloride resin mixed with various additives.

You'll often find plasticizers included for flexibility and stabilizers to boost heat and UV resistance. Phthalate plasticizers are common, but there's a push for safer, bio-based alternatives.

When applied to materials like textiles or metals, this coating enhances durability, water resistance, and overall appearance.

What Is PVC Film?

PVC film is a versatile thermoplastic material you can use in various applications, such as packaging and crafting.

It's available in different thicknesses and forms, both rigid and flexible. You'll appreciate its durability and chemical resistance, which make it ideal for demanding environments.

Plus, with options for colors and finishes, you can customize it to suit your needs.

Whether you're creating signage or protective covers, PVC film offers great functionality.

Conclusion

To summarize, PVC film's unique composition and production methods make it a versatile material for various applications. Its impressive properties, combined with a range of additives, enhance its performance. While you should consider the environmental impacts, the economic benefits and market trends highlight PVC film's continued relevance. Whether you're looking to use it for packaging, construction, or other purposes, understanding its characteristics can help you make informed decisions in your projects.