When choosing between steel and plastic bands, consider your needs for strength, flexibility, and environmental resistance. Steel straps offer higher load capacity, durability, and resistance to stretching, making them ideal for heavy-duty applications. Plastic bands are lightweight, flexible, and excel in weather conditions while being easier to handle, but with lower strength. To find out which material fits your specific tasks and eco-friendly options, keep exploring the key differences further.

Key Takeaways

- Steel straps offer higher load capacity and durability, ideal for heavy-duty applications, while plastic bands provide flexibility and lightweight convenience.

- Steel bands resist stretching and maintain tension under heavy loads, whereas plastic straps are more elastic but may overstretch in certain conditions.

- Plastic straps are corrosion-resistant and suitable for outdoor environments, whereas steel requires coatings to prevent rust.

- Steel straps generally have higher upfront costs but are more recyclable and reusable, reducing long-term environmental impact.

- Choice between steel and plastic depends on load requirements, environmental conditions, cost considerations, and sustainability goals.

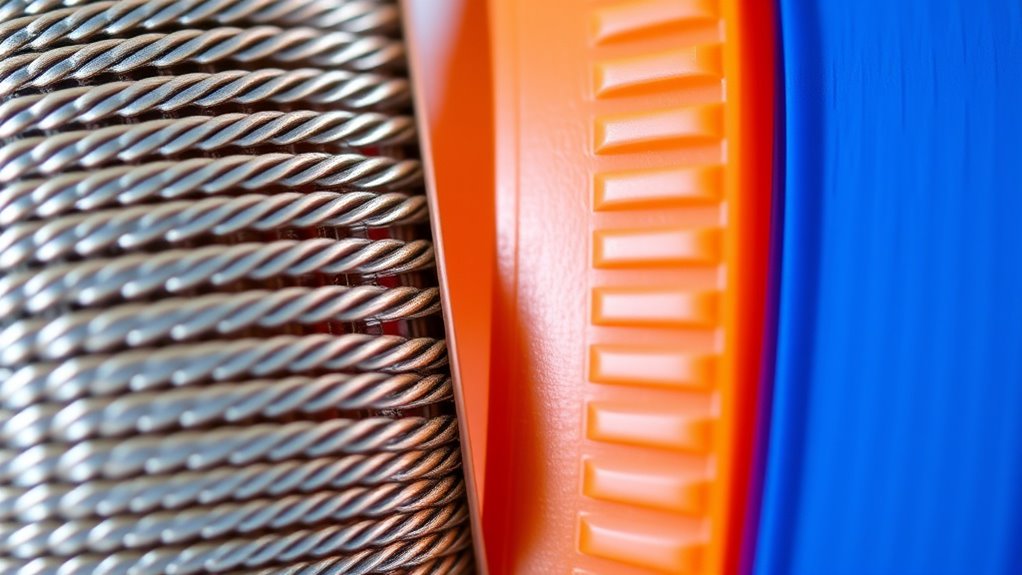

Types and Composition of Strapping Materials

There are several common types of strapping materials, each designed for specific packaging needs. You’ll find alternative materials like polypropylene and polyester, which offer lightweight yet durable options. These materials often feature innovative designs that improve flexibility, elongation, and resistance to environmental factors. For example, plastic straps with special coatings prevent slipping and corrosion, making them suitable for diverse conditions. Steel straps, though traditional, are also evolving with new alloys and coatings that enhance corrosion resistance and flexibility. The choice of material depends on your specific requirements, whether you prioritize cost, weight, or environmental factors. Additionally, understanding the metal composition of steel straps can help you select options with better durability and corrosion resistance. Modern coating technologies have further improved the longevity and performance of steel strapping, especially in harsh environments. The development of environmentally friendly materials also supports sustainable packaging practices, reducing ecological impact. Furthermore, advancements in dog names have led to more personalized and unique options, aligning with specific preferences or needs. Incorporating environmental considerations into material selection can also lead to more sustainable packaging solutions.

Strength and Load-Bearing Capacity

Understanding the tensile strength of different strapping materials helps you choose the right one for heavy loads. You’ll notice some straps resist stretching better, maintaining stability under pressure. Knowing their maximum load limits guarantees your packages stay secure without risking failure. Additionally, selecting the appropriate material type can optimize performance based on specific application needs. For example, durability is crucial in applications like survivalist scenarios where materials must withstand harsh environmental conditions, emphasizing the importance of durability. Furthermore, considering industry standards ensures the straps meet safety and quality requirements for various industrial uses. Incorporating material properties such as flexibility and chemical resistance can further enhance the suitability of the straps for different environments.

Tensile Strength Comparison

When comparing the tensile strength of different strapping materials, it becomes clear that their ability to withstand load without breaking varies considerably. Steel bands generally have higher tensile strength, offering superior load-bearing capacity and snap resistance. Plastic straps, while more flexible, often have lower tensile strength but better elongation properties, allowing them to stretch slightly under pressure without snapping. Proper selection of strapping material depends on the specific application and required performance characteristics, including filtration and pump protection for consistent operation. Additionally, understanding the material properties such as ductility and elasticity is essential for optimizing performance in various scenarios. Recognizing the importance of mammography guidelines can inform safety and effectiveness in breast cancer detection, much like choosing the appropriate strapping material ensures optimal performance in securing loads.

Incorporating knowledge of exploration resilience can also help in assessing the durability of materials under different environmental conditions, ensuring reliability during transportation and storage.

Stretch Resistance Differences

Stretch resistance determines a strapping material’s ability to maintain tension under load without breaking or deforming excessively. The elasticity characteristics influence how much a band can stretch before reaching its breakage threshold. Steel bands typically have low elasticity, meaning they resist stretching and provide consistent tension. Plastic bands, however, often have higher elasticity, allowing more elongation but risking overstretching if not properly tensioned. Understanding these differences helps you select the right material for your needs: elasticity characteristics impact how much tension the strap can sustain before failing. The load-bearing capacity of each material also plays a crucial role in determining suitability for various applications. Additionally, the durability of the material under different environmental conditions can influence long-term performance. For example, environmental resistance is a key factor in selecting a strap for outdoor or harsh environments. – Steel bands offer high strength with minimal stretch, ideal for heavy loads. – Plastic bands provide flexibility but can stretch beyond safe limits. – Breakage thresholds vary based on material and quality. – Choosing the right band depends on balancing stretch resistance with load requirements.

Maximum Load Limits

Maximum load limits define how much weight a strapping material can safely support without failing. Steel bands typically provide higher load capacities due to their superior strength and minimal stretch, maintaining stability under heavy loads. Strength and load-bearing capacity are crucial considerations when selecting the appropriate strapping material. Plastic bands, on the other hand, often have lower maximum load limits but offer greater band elasticity, allowing some stretch under tension, which can help absorb shocks. When choosing between them, consider corrosion resistance; steel bands are more prone to rust unless coated, potentially reducing their load capacity over time. Plastic bands generally resist corrosion better, maintaining their strength longer in humid or corrosive environments. Knowing these load limits helps you select the right material for your specific application, ensuring secure, safe packaging without risking failure. Additionally, understanding the materials’ durability can help determine their suitability for long-term or repeated use. Proper storage conditions and handling can also significantly impact their performance and lifespan, especially for steel bands. Incorporating proper maintenance can also extend their effective lifespan and performance.

Flexibility and Ease of Use

Flexibility and ease of use are key advantages that make strapping materials versatile for various applications. You’ll find that plastic bands typically offer superior ease of installation, requiring less effort and tools, which speeds up your workflow. Their adjustability features let you tighten or loosen straps quickly, ensuring secure fits across different loads. Steel bands, while less flexible, provide consistent tension once applied, but may need specialized tools for adjustment. When selecting between the two, consider how easily you can handle the material in your environment. Factors like the following influence your choice:

- Quick application without extensive training

- Ability to make on-the-fly adjustments

- Compatibility with hand or automated tools

- Ease of tensioning and re-tensioning during use

Durability and Resistance to Elements

When selecting strapping materials, durability and resistance to environmental elements play a vital role in ensuring your loads stay secure over time. Steel bands offer high strength but can corrode without proper coating, affecting long-term corrosion resistance. Plastic bands excel in weather durability, resisting moisture and UV damage, but may weaken under extreme conditions. To help you compare, consider this table:

| Feature | Steel Bands | Plastic Bands |

|---|---|---|

| Corrosion Resistance | Moderate (needs coating) | Excellent |

| Weather Durability | Limited (rust risk) | High (UV & moisture resistant) |

| Longevity | Long-lasting with maintenance | Shorter lifespan without reinforcement |

Choose based on your environmental exposure and load needs.

Cost and Overall Investment

Choosing the right strapping material involves considering both upfront costs and long-term investment. Pricing differences between steel and plastic bands can be significant, affecting your initial expenses. Steel straps typically cost more initially but may save you money over time due to their strength and durability. Plastic bands are cheaper upfront but might require more frequent replacements, increasing long-term costs. To make a smart choice, think about:

- How often you’ll need to replace or re-secure straps

- The impact of potential damage or failure

- Maintenance and handling expenses

- Overall durability and lifespan of the material

Balancing these factors helps you assess whether the higher upfront price of steel pays off over its longer lifespan or if plastic bands are more economical for your specific needs.

Safety Considerations and Handling

Safety considerations are essential when handling strapping materials, as improper use can lead to injuries or equipment damage. Always follow handling precautions to protect yourself and ensure safe operations. Wear appropriate safety gear, such as gloves and eye protection, to guard against sharp edges and potential recoil during tensioning. When cutting or removing straps, use tools designed for the material and avoid forceful actions that could cause slips or flying debris. Keep your workspace clear of obstacles, and handle the straps carefully to prevent pinching or cuts. Regularly inspect straps and equipment for damage before use. Staying attentive and following safety protocols minimizes risks and promotes a safe, efficient workflow when working with steel or plastic bands.

Common Applications and Industry Usage

Have you ever wondered where strapping materials are most commonly used? They play a essential role in many industries, ensuring products stay secure during transit and storage. Steel and plastic bands are widely used in:

- Shipping large pallets for transportation efficiency

- Securing heavy loads in construction sites

- Bundling products to improve packaging aesthetics

- Enhancing branding opportunities through custom-printed straps

These applications highlight how strapping not only provides stability but also influences presentation and brand visibility. Steel straps are preferred for their strength in heavy-duty tasks, while plastic straps offer flexibility and a cleaner look. In both cases, industry usage depends on the specific needs of durability, appearance, and branding potential.

Environmental Impact and Recycling Options

You should consider how different strapping materials are recycled, as processes vary widely and impact the environment differently. Comparing their ecological footprints can help you select more sustainable options. Additionally, understanding reuse and disposal methods guarantees you minimize waste and environmental harm.

Recycling Processes Differences

Recycling processes for different strapping materials vary substantially in their environmental impact and available options. When recycling steel and plastic bands, material sorting is vital to guarantee proper processing. Steel straps are typically melted down and reformed, making recycling straightforward with minimal contamination. Plastic bands, however, require more careful sorting to separate types like polypropylene or polyester, which affects their recycling efficiency.

Key considerations include:

- Steel recycling involves high-temperature melting and reformation.

- Plastic recycling depends on accurate material sorting to avoid contamination.

- Recycling steel often results in a near-infinite loop of reuse.

- Plastic recycling can be more complex due to diverse polymer types and contamination risks.

Environmental Footprint Comparison

When comparing the environmental footprints of steel and plastic straps, it’s clear that their impacts extend beyond recycling processes alone. You should consider biodegradability concerns and carbon footprint analysis. Steel straps typically have a higher initial energy requirement but are highly recyclable, reducing long-term waste. Plastic straps, especially non-biodegradable types, pose significant biodegradability concerns, lingering in ecosystems for years. Here’s a quick comparison:

| Aspect | Steel Straps | Plastic Straps | Key Considerations |

|---|---|---|---|

| Recycling Options | Widely recyclable | Recyclable but less common | Recycling reduces environmental impact |

| Biodegradability | Non-biodegradable | Often non-biodegradable | Environmental persistence |

| Carbon Footprint | Moderate, high in production | Lower in production, longer lifespan | Carbon footprint varies by lifecycle |

| Environmental Impact | Recyclable, durable | Pollution risk, waste issues | Long-term ecosystem effects |

Your choice affects environmental sustainability, highlighting the importance of considering both impact and recycling options.

Reuse and Disposal Options

Choosing the right reuse and disposal strategies for straps can markedly reduce their environmental impact. Recycling challenges often hinder effective processing, especially for plastic bands, which can be difficult to recycle due to contamination or mixed materials. Proper disposal methods are essential; steel straps can be recycled easily, while plastic options may require specialized facilities. To minimize waste, consider reusing straps whenever possible, such as for future bundling needs. When disposal is necessary, prioritize recycling over landfilling to reduce landfill accumulation. Keep in mind:

- Steel straps are highly recyclable and can be reused multiple times

- Plastic straps pose recycling challenges and may need special disposal

- Reuse extends the lifespan and reduces waste

- Proper disposal methods help lessen environmental harm and conserve resources

Frequently Asked Questions

How Do Steel and Plastic Bands Compare in Recycling Processes?

You might wonder how steel and plastic bands compare in recycling. Steel bands have a lower environmental impact because they’re 100% recyclable and retain value, making recycling cost-efficient. Plastic bands, while recyclable, often require special processes and may have a higher environmental footprint due to plastic waste. Overall, steel offers better sustainability and cost efficiency in recycling, helping you reduce environmental impact and save money in the long run.

What Are the Best Practices for Disposing of Used Strapping Materials?

Imagine your used strapping as a message to the environment. To reduce environmental impact, you should recycle or reuse steel and plastic bands whenever possible. Proper waste management involves separating materials and following local recycling guidelines. Avoid discarding them in regular trash, as this can harm ecosystems. By responsibly disposing of used strapping, you protect nature’s message, ensuring a cleaner planet and sustainable waste practices.

Can Steel and Plastic Bands Be Reused Multiple Times Effectively?

You can reuse steel and plastic bands effectively, but recycling efficiency varies. Steel bands offer high reuse durability, making them ideal for multiple uses if handled carefully. Plastic bands, while lightweight, may weaken over time, reducing their reuse potential. To maximize both materials’ reuse, inspect them for damage before reusing and ensure proper storage. This approach helps you get the most out of your strapping options while promoting sustainable practices.

How Do Temperature Fluctuations Affect the Performance of Each Band Type?

Temperature fluctuations cause thermal expansion and contraction in both steel and plastic bands, affecting their performance. You’ll notice steel bands expand in heat and contract in cold, which can loosen or tighten the strap unpredictably. Plastic bands are more sensitive; they tend to weaken and become brittle in cold, while heat can cause them to soften or stretch. These variations can compromise your load security over time.

Are There Specific Safety Certifications for Steel or Plastic Strapping Products?

Imagine you’re securing valuable cargo, and safety certifications matter. Yes, both steel and plastic strapping products must meet specific safety standards and certification requirements. For instance, the OSHA or ISO certifications verify the straps’ strength and safety. These certifications confirm that the products adhere to industry safety standards, giving you confidence in their performance and safety during transport. Always check for proper certification before choosing your strapping material.

Conclusion

Choosing between steel and plastic strapping depends on your specific needs. Steel offers unmatched strength and durability, perfect for heavy-duty loads, while plastic provides flexibility and ease of use for lighter applications. Consider your budget, safety, and environmental impact before making a decision. Remember, your choice can make or break your packaging game—so pick wisely, because the right strap can turn a simple task into a breeze or a battle!