Innovations in shrink wrap films now focus on sustainability, offering biodegradable and recycled materials that reduce environmental impact without sacrificing protection. Automation plays a key role, allowing you to easily switch between film types and improve efficiency with minimal human effort. Future advances include smart films embedded with sensors to monitor product condition or tampering. Exploring these cutting-edge changes will help you stay ahead in eco-friendly, flexible packaging solutions.

Key Takeaways

- Development of biodegradable and plant-based shrink wrap films to reduce environmental impact.

- Integration of smart, sensor-embedded shrink films for real-time product monitoring.

- Advancements in recycled plastics enhancing sustainability without compromising durability.

- Automation technologies enabling rapid, precise application of customizable shrink wrap solutions.

- Innovations supporting versatile, eco-friendly packaging adaptable to diverse products and future needs.

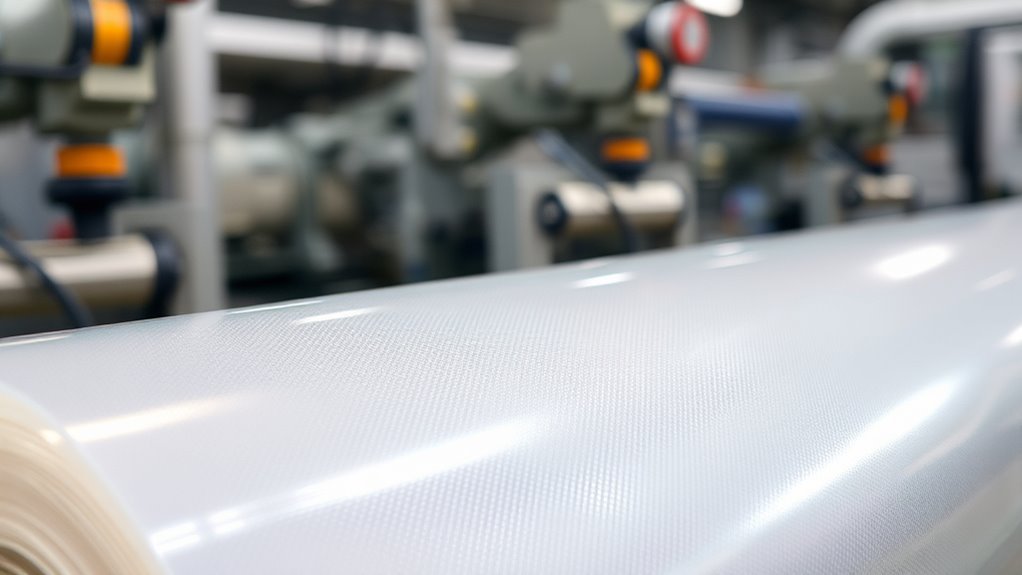

Recent advancements in shrink wrap films are transforming packaging industries by offering stronger, more flexible, and environmentally friendly options. These innovations address the growing demand for sustainable materials and streamline production through automated packaging processes. As a result, you now have access to solutions that not only protect your products better but also reduce environmental impact and improve efficiency.

Recent shrink wrap innovations enhance protection, flexibility, and sustainability for smarter, eco-friendly packaging solutions.

Sustainable materials play an essential role in these new developments. Traditional shrink wrap films, often made from petroleum-based plastics, pose environmental challenges due to their non-biodegradable nature. Manufacturers are now shifting towards eco-friendly alternatives, such as biodegradable polymers, recycled plastics, and plant-based bioplastics. These materials break down more quickly in the environment, helping to reduce waste and pollution. When you choose shrink wrap films made from sustainable materials, you’re actively participating in a greener supply chain, aligning your business practices with eco-conscious values. These films provide the same level of protection and durability as conventional options, guaranteeing your products stay secure while minimizing ecological footprints.

Another major innovation is the integration of automated packaging systems. Advanced machinery now enables you to efficiently apply shrink wrap films at high speeds with minimal human intervention. Automated packaging reduces labor costs and human error, leading to more consistent quality and faster throughput. You can set up your production line to automatically measure, cut, and apply the shrink film precisely around your products. This not only speeds up your operations but also guarantees tight, uniform packaging that enhances product presentation and security. Automation also allows for seamless integration with other manufacturing processes, creating a more streamlined and cost-effective workflow. As a result, you can handle larger volumes without sacrificing quality, making your packaging process more scalable and responsive to market demands.

These innovations also facilitate better customization options. With automated systems, you can easily switch between different film types and sizes, enabling you to tailor packaging for diverse products. This flexibility is essential in today’s dynamic market, where product varieties and packaging requirements continually evolve. Furthermore, the development of intelligent shrink films with embedded sensors or indicators is on the horizon, promising even more sophisticated packaging solutions that monitor product condition or indicate tampering. Notably, advancements in fetal movement sensing techniques are improving prenatal care, paralleling how innovative materials and automation are advancing packaging technology.

Frequently Asked Questions

How Do Shrink Wrap Films Impact Environmental Sustainability?

Shrink wrap films impact environmental sustainability by offering biodegradable alternatives, reducing plastic waste. You can choose eco-friendly options that break down more quickly, lessening landfill burden. Additionally, energy-efficient manufacturing processes lower carbon emissions, making production more sustainable. By opting for these innovations, you help decrease environmental impact, promote recycling, and support a greener future. Your choices in shrink wrap films contribute profoundly to reducing pollution and conserving resources.

Are There Specific Industries That Benefit Most From New Shrink Wrap Innovations?

You’ll find food packaging and pharmaceutical applications benefit most from new shrink wrap innovations. These industries require high-quality, secure, and versatile packaging solutions, which advanced shrink wrap films provide. You’ll notice improved durability, clarity, and environmental friendliness that meet strict regulations. This helps you guarantee product safety, extend shelf life, and reduce waste, making these innovations essential for maintaining quality standards and consumer trust in these highly sensitive sectors.

What Safety Considerations Are Associated With Advanced Shrink Wrap Materials?

You should be aware that over 60% of packaging-related accidents involve chemical hazards. When working with advanced shrink wrap materials, follow strict handling protocols to prevent chemical exposure. Always wear appropriate protective gear, ensure proper ventilation, and handle materials carefully. This minimizes risks like inhalation or skin contact, making safety a top priority. Staying informed and cautious helps protect you and guarantees safe, effective use of these innovative films.

How Long Do Modern Shrink Wrap Films Typically Last During Storage?

Modern shrink wrap films typically last between 12 to 24 months during storage if you maintain proper conditions. Your shelf life depends on factors like temperature, humidity, and exposure to sunlight. To maximize longevity, store the films in a cool, dry, and dark environment, avoiding extreme temperatures and moisture. Proper storage conditions help preserve the film’s quality, ensuring it remains effective for your packaging needs over time.

Can Innovative Shrink Wrap Films Be Recycled or Reused Effectively?

While traditional shrink wrap films often end up in landfills, innovative options make recycling and reuse more feasible. You can opt for biodegradable alternatives or reusable packaging options that are designed to be recycled effectively. These films reduce environmental impact and support sustainability goals, making your packaging choices both eco-friendly and practical. Embracing these innovations allows you to minimize waste without sacrificing the protective qualities of shrink wrap.

Conclusion

As you explore the latest innovations in shrink wrap films, you see the possibilities expanding, the durability improving, and the sustainability advancing. You witness films that protect better, shrink tighter, and recycle easier. You embrace a future where packaging is smarter, stronger, and more eco-friendly. By staying informed and adaptable, you’re part of a movement transforming packaging—making it safer for your products, kinder to the environment, and more efficient for your business.