Protective coatings for paper and cardboard include wax, polymers, and advanced innovations that boost durability, moisture resistance, and surface quality. Wax coatings offer a smooth, eco-friendly barrier that’s cost-effective and easy to apply. Poly coatings, on the other hand, provide stronger protection against water and wear, ideal for demanding environments. As technologies evolve, eco-friendly and nanotech solutions are becoming more common. To discover how these options can meet your needs, keep exploring more details below.

Key Takeaways

- Different coatings like acrylic, polyurethane, wax, and biodegradable options enhance paper and cardboard durability, moisture resistance, and surface aesthetics.

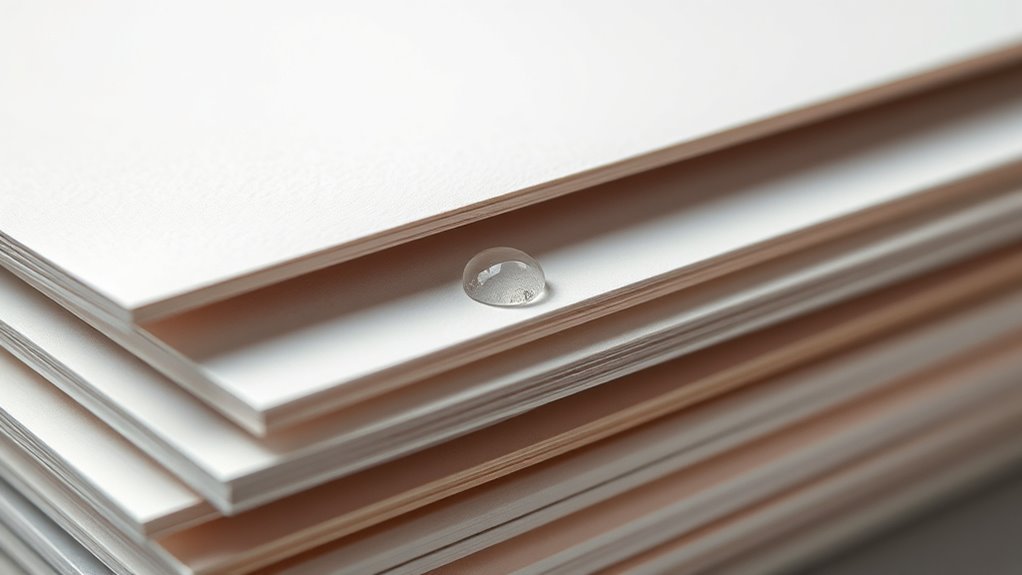

- Wax coatings provide moisture resistance and a smooth finish, while poly coatings offer superior protection and physical strength.

- Advanced technologies, including nanotech and eco-friendly formulations, improve coating performance and sustainability.

- Application methods such as spraying, rolling, dipping, and blade coating influence adhesion, appearance, and long-term durability.

- Environmental considerations favor biodegradable and eco-friendly coatings, balancing performance with sustainability goals.

Types of Protective Coatings for Paper and Cardboard

There are several types of protective coatings available for paper and cardboard, each designed to enhance durability and resistance. These coatings influence the surface texture, making it smoother or more textured depending on your needs. Coating adhesion is vital; a strong bond ensures the coating stays intact during handling and exposure to elements. Acrylic and polymer coatings provide excellent adhesion and a glossy finish, improving surface durability. Polyurethane coatings offer superior resistance to moisture and wear, with good surface texture control. Wax coatings, although not covered here, also alter surface feel and adhesion properties. Choosing the right type depends on your product’s specific requirements, guaranteeing the coating maintains its protective qualities without compromising the paper’s surface texture or adhesion strength. Additionally, understanding the coating adhesion process can help optimize the longevity and performance of protective layers on paper and cardboard. For instance, selecting coatings that are eco-friendly can also contribute to sustainable packaging solutions. It is essential to consider the surface properties when selecting a coating to ensure compatibility with the intended application. Moreover, considering the material compatibility ensures that the coating interacts properly with different types of paper or cardboard, enhancing overall effectiveness. To further improve coating performance, proper surface preparation can significantly influence adhesion strength and overall durability.

Benefits of Applying Wax Coatings

Applying wax coatings to paper and cardboard offers several practical benefits that enhance product performance. First, wax provides a smooth surface finish, making handling and printing easier. Second, it offers excellent moisture resistance, protecting contents from humidity. Third, wax coatings contribute to aesthetic enhancement by giving a glossy, attractive appearance. Fourth, they create a barrier that reduces dirt and grease penetration. These benefits help ensure your product looks professional and remains durable during storage and transportation. The surface finish achieved with wax not only improves visual appeal but also adds a tactile quality that consumers appreciate. Additionally, understanding creative practice can inspire innovative ways to improve or modify coating techniques for better results. Incorporating technological advancements into application methods can further optimize coating uniformity and durability. Exploring material compatibility is essential for achieving the best adhesion and longevity of the coating. Moreover, selecting the appropriate coating based on regional climate considerations can significantly impact its effectiveness and longevity. Considering environmental impacts can also guide sustainable choices in coating materials and practices. Overall, wax coatings are a cost-effective way to boost both the functional and aesthetic qualities of paper and cardboard, making your products stand out in the marketplace.

The Role of Poly Coatings in Enhancing Durability

Poly coatings markedly boost your paper or cardboard’s durability by making it more resistant to moisture and physical damage. This protection helps your materials withstand harsh conditions and handling better. Additionally, choosing eco-friendly sustainable materials for coatings can enhance environmental benefits while providing effective protection. Incorporating digital privacy strategies can further safeguard your sensitive information from exposure and misuse. Furthermore, advancements in AI integration are opening new possibilities for developing smarter, more adaptable coating solutions that respond to environmental stresses. Staying informed about innovative coating technologies can encourage the adoption of cutting-edge solutions that improve longevity and sustainability. Exploring environmentally friendly options can also contribute to more sustainable packaging solutions.

Improved Moisture Resistance

Ever wondered how paper and cardboard can withstand exposure to moisture without falling apart? Poly coatings play a vital role in boosting water resistance by forming effective moisture barriers. They prevent water penetration, protecting the material’s integrity. To achieve this, poly coatings:

- Create an impermeable layer that blocks moisture ingress

- Enhance the overall water resistance of the substrate

- Reduce risks of warping, swelling, and deterioration

- Extend product lifespan in humid or wet environments

- Utilize advanced coating technologies to further improve performance

These coatings improve durability while maintaining flexibility. By forming a reliable moisture barrier, poly coatings ensure your paper or cardboard resists moisture damage, keeping it functional and intact even in challenging conditions. This is especially important in protective packaging applications where exposure to moisture can compromise quality. Additionally, ongoing innovations in coating formulations continue to expand the effectiveness and environmental friendliness of these protective solutions. For example, the development of eco-friendly biodegradable coatings aims to reduce environmental impact. This makes them ideal for packaging, labels, and other moisture-prone applications.

Enhanced Physical Strength

To guarantee paper and cardboard materials can withstand rough handling and mechanical stresses, poly coatings actively enhance their physical strength and durability. They do this through fiber reinforcement, which increases the material’s resistance to tearing and crushing. Poly coatings also improve surface adhesion, creating a strong bond between the coating and the paper fibers, reducing the risk of delamination. This reinforcement helps the substrate resist deformation, ensuring it maintains its shape under stress. By strengthening the surface, poly coatings prevent damage from impacts and repeated use, extending the lifespan of packaging and other paper products. Additionally, cutting-edge technology in coating formulations continues to advance, providing even more effective protection against environmental factors. These innovations often incorporate predictive modeling to optimize coating formulations for specific applications, further enhancing durability. Overall, these coatings provide a resilient barrier that enhances durability, making your paper and cardboard more capable of enduring rough conditions while maintaining their functional integrity.

Comparing Wax and Poly Coatings: Which Is Right for Your Project?

Choosing between wax and poly coatings depends on your project’s durability needs, environmental goals, and budget. Wax offers a natural, eco-friendly option with easier application, while poly provides stronger protection but may be more costly and less sustainable. Understanding these differences helps you select the right coating for your specific requirements. Additionally, selecting the appropriate coating material can influence the overall protective qualities and longevity of your paper or cardboard.

Durability and Protection

When it comes to protecting paper and cardboard, understanding the durability of different coatings is essential. Wax offers a flexible, biodegradable option that provides basic moisture resistance, but may wear over time. Poly coatings, on the other hand, deliver superior durability and chemical resistance, making your packaging more resilient. Consider these factors:

- Moisture resistance: Poly generally outperforms wax in wet conditions.

- Aesthetic enhancements: Poly can create a glossy finish, while wax offers a matte look.

- Biodegradable options: Wax is often biodegradable, but certain poly types can be environmentally friendly.

- Longevity: For long-term protection, poly coatings tend to last longer without deterioration.

Choosing between them depends on your project’s durability needs and aesthetic preferences, balancing eco-conscious choices with performance.

Environmental Impact Considerations

Have you considered how the environmental impact of your paper and cardboard coatings influences your sustainability goals? Wax coatings often come from renewable resources and are biodegradable, making them a more eco-friendly choice. In contrast, poly coatings, especially plastics, can have a significant lifecycle environmental impact due to their non-biodegradable nature and reliance on fossil fuels. When comparing options, look for biodegradable alternatives that reduce landfill waste and lower overall carbon footprint. Evaluating the lifecycle environmental impact—from production to disposal—helps you make informed decisions aligned with sustainability efforts. Choosing coatings that minimize environmental harm supports responsible manufacturing and end-of-life management, ensuring your projects contribute positively to environmental preservation.

Application and Cost Differences

Applying wax coatings typically involves simpler, more straightforward processes that can be integrated into existing manufacturing lines with minimal adjustments. This simplicity often results in lower initial setup costs and faster application times. When considering cost analysis, wax coatings usually have lower material costs but may require more frequent reapplication, impacting long-term expenses. In contrast, poly coatings involve more complex application techniques, such as extrusion or spraying, which can increase equipment and labor costs upfront.

- Wax coatings: Easy application, lower initial costs, suitable for quick projects.

- Poly coatings: Advanced application methods, higher initial investment, longer-lasting protection.

- Cost analysis: Balance between material, labor, and reapplication frequency.

- Decision factors: Project duration, budget constraints, and desired durability influence the choice.

Innovative Coating Technologies and Trends

Innovative coating technologies are transforming the paper and cardboard industry by offering enhanced protective properties while reducing environmental impact. You now have access to biodegradable alternatives that break down naturally, cutting down waste. Nanotechnology innovations are also making coatings smarter, creating ultra-thin, durable barriers that improve moisture resistance without adding bulk. These advances help meet eco-friendly standards and elevate product performance. Here’s a quick overview:

| Technology | Benefit |

|---|---|

| Biodegradable Coatings | Eco-friendly, reduces landfill waste |

| Nanotech Enhancements | Superior barrier properties, thin layers |

| Sustainable Materials | Lower environmental footprint |

These trends ensure your packaging stays protected and sustainable.

Application Methods for Protective Paper Coatings

Wondering how protective coatings are applied to paper and cardboard? You typically choose from several methods to guarantee the best surface finish and coating adhesion. First, you can use rolling or metallizing, which involves passing the material through rollers for a smooth, uniform layer. Second, spraying applies coatings evenly, ideal for complex surfaces. Third, dipping immerses the substrate in the coating, providing thorough coverage. Finally, coating by blade or bar spreads the material in a precise thickness, enhancing surface finish. Each method influences coating adhesion and the final appearance, ensuring the protective layer bonds well and meets your desired specifications. Selecting the right application method ensures durability and a high-quality protective coating for paper and cardboard.

Industry-Specific Uses of Protective Coatings

Protective coatings for paper and cardboard serve a variety of industry-specific purposes, ensuring materials perform reliably in demanding environments. In packaging design, these coatings improve durability, moisture resistance, and barrier properties, helping your products withstand shipping and handling. They also enhance print quality, providing a smooth surface that results in vibrant colors and sharp images, which boosts your product’s visual appeal. For food packaging, coatings prevent contamination and extend shelf life, while in retail, they protect labels and graphics from wear and tear. In industrial applications, coatings guard against chemicals and abrasion, maintaining structural integrity. By choosing the right protective coating, you optimize your packaging’s performance and presentation, ensuring your products remain protected, attractive, and compliant with industry standards.

Environmental Considerations and Eco-Friendly Options

Have you considered how the environmental impact of protective coatings for paper and cardboard influences your choices? Biodegradability concerns are increasingly important as waste accumulates. To address this, look for eco-friendly alternatives that reduce environmental harm. Consider these options:

Considering biodegradable coatings helps reduce environmental impact of paper and cardboard packaging.

- Use water-based coatings instead of solvent-based ones.

- Opt for biodegradable waxes that break down naturally.

- Select coatings made from renewable, plant-based materials.

- Avoid coatings containing harmful chemicals or non-biodegradable polymers.

Future Developments in Paper and Cardboard Surface Protection

Advancements in nanotechnology and biodegradable materials are driving the future of surface protection for paper and cardboard. You can expect innovative biodegradable coatings that break down naturally, reducing environmental impact. Nanotechnology advancements enable the creation of ultra-thin, highly effective protective layers that enhance durability without adding bulk. These nanocoatings can provide water resistance, grease barrier, and antimicrobial properties, all while remaining eco-friendly. Researchers are focusing on developing smarter coatings that respond to environmental conditions, extending product life and reducing waste. As these technologies mature, you’ll see more sustainable options replacing traditional wax and polymer coatings. The integration of biodegradable coatings with nanotech offers a promising path toward stronger, greener surface protection solutions for paper and cardboard products.

Frequently Asked Questions

How Do Protective Coatings Affect the Recyclability of Paper and Cardboard?

Protective coatings can impact how easily you can recycle paper and cardboard. When coatings like wax or polymer are involved, you might need coating removal during the recycling process, which adds complexity and cost. This can slow down recycling and sometimes reduce the quality of recycled materials. So, coatings influence recyclability by making coating removal necessary, potentially complicating and lengthening the recycling process.

Are There Health Risks Associated With Certain Coating Chemicals?

Think of coating chemicals as hidden pirates lurking in your paper, potentially risking your health. You might be exposed to chemical residues during manufacturing or disposal, raising concerns about chemical exposure and health safety. While many coatings are safe, some contain additives that could cause skin or respiratory irritation. To stay safe, choose products with non-toxic coatings and follow proper handling guidelines, keeping your health shipshape.

Can Protective Coatings Be Customized for Specific Environmental Conditions?

You can definitely customize protective coatings to suit specific environmental conditions. By adjusting the coating formulation, you guarantee better environmental adaptation, whether it’s moisture, temperature, or chemical exposure. This tailored approach helps optimize performance and durability. You work with manufacturers to select and modify materials, ensuring the coating effectively protects your paper or cardboard in challenging environments, ultimately improving product lifespan and reliability.

What Are the Cost Differences Between Wax and Poly Coatings?

You’ll find that the cost comparison between wax and poly coatings varies based on application costs and material expenses. Usually, wax coatings are more affordable upfront, but they might require more frequent reapplication, increasing overall costs. Poly coatings tend to have higher initial expenses but offer longer-lasting protection with lower ongoing application costs. Consider your specific needs and environmental factors to determine which coating provides better value for your budget.

How Do Coatings Impact the Biodegradability of Paper Products?

Think of coatings as the gatekeepers of biodegradability, influencing how quickly your paper breaks down. Coatings like wax often enhance biodegradation rate, making your paper more eco-friendly, while poly coatings can slow this process, impacting environmental impact. You can choose coatings wisely to balance durability and sustainability, ensuring your paper products serve their purpose without hindering natural decomposition, consequently supporting a greener future.

Conclusion

Choosing the right protective coating is like giving your paper and cardboard a suit of armor—whether it’s the warm embrace of wax or the tough resilience of poly. By understanding your project’s needs and the latest innovations, you can shield your materials from life’s spills and tears, ensuring they stay vibrant and strong. Think of coatings as your secret weapon, turning everyday paper into a fortress that stands the test of time and trend.