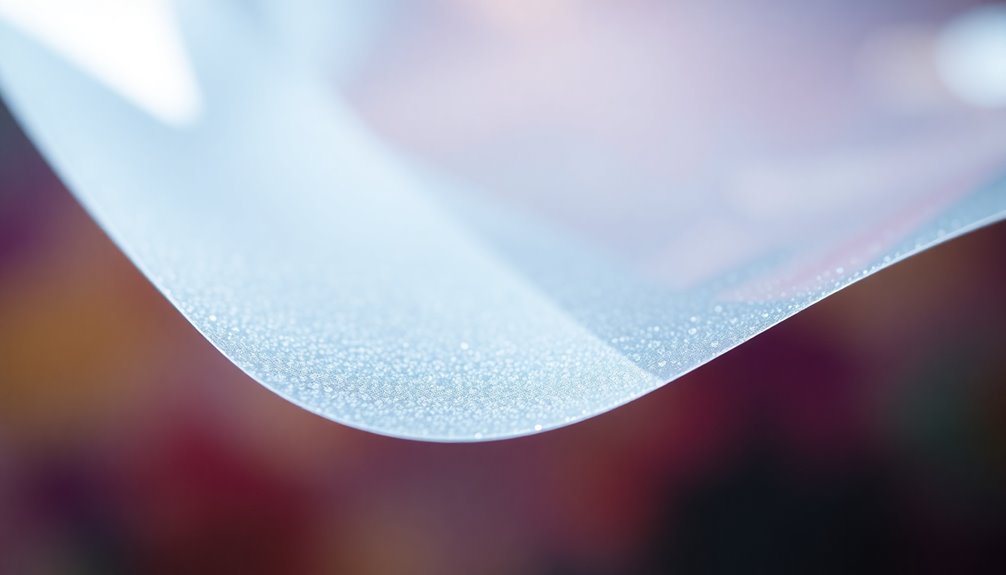

Packaging films for pharmaceuticals play a crucial role in protecting medicines from environmental threats like moisture, oxygen, and light. These high barrier films ensure your products stay stable and effective throughout their shelf life, even under challenging conditions. They are designed to withstand sterilization processes without degrading, maintaining both safety and integrity. If you want to discover how these advanced materials enhance medicine preservation and meet stringent standards, keep exploring further.

Key Takeaways

- High barrier films protect pharmaceuticals from moisture, oxygen, light, and contaminants, ensuring product stability.

- Compatibility with sterilization methods like gamma or EO is essential to maintain film integrity and drug safety.

- Multilayer structures and specialized materials enhance barrier, mechanical strength, and sterilization resistance.

- Material innovation enables films to withstand storage conditions while preventing degradation of sensitive active ingredients.

- Proper design balances flexibility, sealing performance, and durability to prevent leaks and contamination throughout the supply chain.

Have you ever wondered how medicines stay safe and effective during storage and transportation? The answer lies in the packaging films used to protect pharmaceutical products. These films are specially engineered to maintain the integrity, stability, and sterility of medicines from manufacturing to end-user. One of the critical aspects of these packaging materials is their barrier properties. These properties determine how well the film can prevent gases, moisture, light, and contaminants from reaching the drug inside. High barrier films, for example, are essential for protecting sensitive active ingredients that degrade when exposed to environmental factors. They keep moisture out, prevent oxygen from causing oxidation, and block UV light that might impair drug potency. The right combination of barrier properties ensures that medicines remain effective throughout their shelf life, even under challenging storage conditions. Creativity can be cultivated by anyone, and innovative packaging solutions often emerge from exploring new materials and techniques.

Another key factor in pharmaceutical packaging films is their ability to withstand sterilization processes. Sterilization methods, such as gamma irradiation, ethylene oxide (EO), or electron beam (e-beam), are often necessary to eliminate microbial contamination before the product reaches consumers. Packaging films must be compatible with these sterilization techniques without compromising their structure or barrier functions. For example, some films may degrade or become brittle when exposed to certain sterilization methods, risking contamination or damage to the drug. Consequently, manufacturers select materials that can endure sterilization without losing their protective qualities. This compatibility ensures that the pharmaceutical product remains sterile and safe during transit and storage.

Designing packaging films for pharmaceuticals involves balancing multiple requirements. They need to be flexible enough for easy packaging and handling but also strong enough to resist tearing and punctures. Additionally, these films should have excellent sealing properties to prevent leaks, which could lead to contamination or spoilage. Many films are multilayered, combining different materials to optimize barrier properties, mechanical strength, and sterilization compatibility. For instance, a film might include a metalized layer to enhance barrier performance or a special polymer that withstands high temperatures during sterilization.

Frequently Asked Questions

How Do Packaging Films Impact Drug Stability Over Time?

You’ll find that packaging films considerably impact drug stability over time by providing essential moisture protection and acting as a light barrier. These features prevent moisture ingress and exposure to harmful light, which can degrade active ingredients. By choosing films with proper barrier properties, you guarantee the drug remains effective and safe longer, reducing the risk of deterioration and maintaining potency throughout its shelf life.

Are There Environmentally Friendly Packaging Film Options for Pharmaceuticals?

Yes, you can choose environmentally friendly packaging films that use biodegradable materials and eco-friendly coatings. These options help reduce environmental impact while maintaining drug stability and safety. By selecting such films, you align with sustainability goals, and often, these innovative materials enhance the overall packaging performance. Consequently, you support eco-conscious practices without compromising the quality and effectiveness of pharmaceutical products, making your packaging more sustainable and responsible.

What Are the Latest Innovations in Pharmaceutical Packaging Films?

You’ll find that the latest innovations in pharmaceutical packaging films include smart materials and antimicrobial coatings. Smart materials respond to environmental changes, enhancing drug stability and safety. Antimicrobial coatings help prevent contamination and extend shelf life. These advancements offer improved protection, compliance with regulations, and sustainability. By adopting these technologies, you guarantee your packaging stays ahead of industry standards, providing safer, more effective solutions for pharmaceutical products.

How Do Packaging Films Prevent Contamination During Storage?

You can depend on packaging films with contamination barriers that effectively prevent dirt, microbes, and moisture from reaching your pharmaceuticals during storage. These films maintain sterility assurance by creating a secure seal, blocking airborne contaminants, and resisting punctures or tears. By choosing high-quality films designed for pharmaceutical needs, you ensure your products stay safe, effective, and compliant with industry standards throughout their shelf life.

Can Packaging Films Be Customized for Specific Drug Formulations?

Yes, you can customize packaging films like tailoring a suit to fit perfectly. With film customization, you mold the material to match your drug formulation’s unique needs—be it moisture barriers, chemical resistance, or light protection. This guarantees your medication stays pristine and effective. By working closely with manufacturers, you craft a film that acts as a bespoke shield, safeguarding your drug’s integrity throughout storage and transportation.

Conclusion

Think of pharmaceutical packaging films as the silent guardians of medicine, shielding your health every day. Like a well-fitted suit that keeps you warm and protected, these films guarantee drugs stay safe and effective until they reach you. Imagine a crucial medication that’s traveled thousands of miles, untouched and pure, thanks to high-quality packaging. Trust in these films, because they’re the invisible armor that safeguards your well-being, every step of the way.