Mono-material films support sustainability by making packaging easier to recycle since they’re made from a single type of polymer. They help reduce waste, lower environmental impact, and promote a circular economy by simplifying collection and reprocessing. These innovative films also use fewer resources, are lighter, and maintain quality, encouraging eco-friendly choices across industries. If you want to discover how these advancements can make packaging more sustainable, there’s more to explore below.

Key Takeaways

- Mono-material films enable easier recycling due to their single polymer composition.

- They support a circular economy by facilitating continuous reuse and reprocessing.

- Using mono-materials reduces packaging waste and lowers environmental impact.

- Innovations in polymers improve the performance and sustainability of mono-material films.

- They promote eco-friendly packaging solutions across various industries.

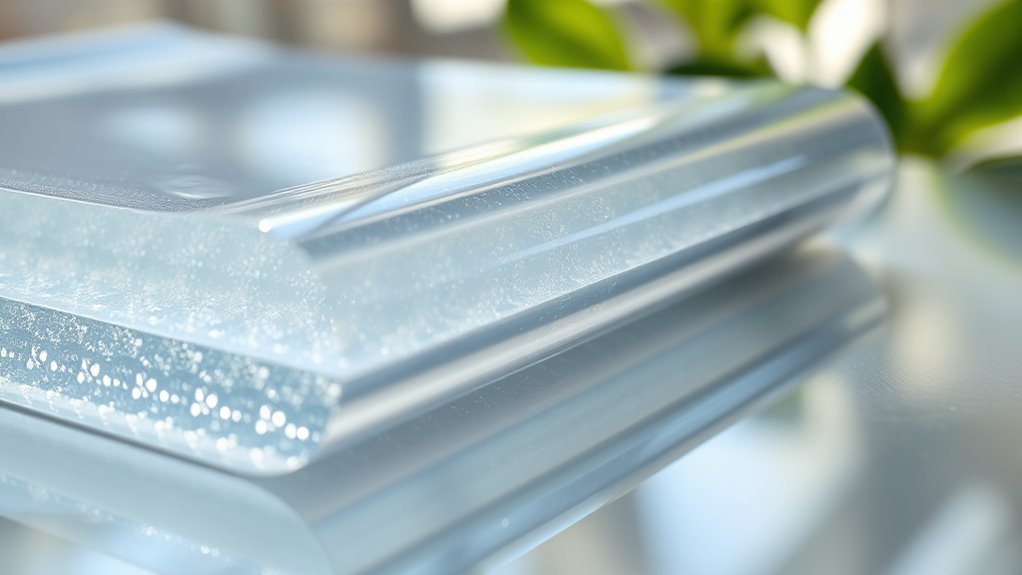

As the demand for sustainable packaging grows, mono-material films have emerged as a promising solution to reduce environmental impact. These films are designed to be more recyclable than traditional multi-layered plastics, addressing one of the biggest hurdles in sustainable packaging: recycling challenges. Conventional packaging often uses complex laminates, making it difficult for recycling facilities to separate and process individual materials. This results in a significant amount of waste ending up in landfills or incinerators. Mono-material films, being made from a single type of polymer, simplify the recycling process. They can be more easily collected, sorted, and reprocessed into new products, closing the loop in the recycling chain. This shift not only promotes environmental sustainability but also encourages manufacturers to adopt cleaner, more efficient production methods.

Material innovations play a vital role in advancing mono-material films. Researchers and industry leaders are continuously developing new polymers that combine strength, flexibility, and barrier properties—all while maintaining compatibility with existing recycling infrastructure. For example, advances in biodegradable polymers and bio-based alternatives are helping create films that degrade more quickly in the environment or are made from renewable resources. These innovations reduce dependence on fossil fuels and minimize the carbon footprint associated with packaging production. Additionally, material scientists are working on enhancing the performance of mono-material films so they can replace multi-layer options without sacrificing functionality. This includes improving moisture barriers, oxygen resistance, and sealability—features essential for preserving product freshness and safety. Innovations in material performance are key to expanding the applicability of mono-material films across diverse industries.

You’ll also notice that material innovations are fostering the development of thinner, lighter films that require fewer resources to produce and transport. This reduces overall packaging waste and lowers the carbon footprint associated with logistics. By focusing on these improvements, manufacturers can offer packaging solutions that meet consumer demands for sustainability while maintaining product quality. As you evaluate different packaging options, consider how mono-material films can streamline recycling efforts and align with eco-friendly goals. They are designed not only to be environmentally responsible but also to support a circular economy, where materials are continuously reused rather than discarded.

Frequently Asked Questions

How Do Mono-Material Films Compare to Multi-Material Films in Cost?

Mono-material films generally cost less than multi-material films due to lower manufacturing expenses and simpler production processes. You’ll find that mono-material options reduce complexity, which streamlines the cost comparison, making them more budget-friendly. Since they require fewer materials and less intricate machinery, your overall manufacturing expenses decrease, providing a cost-effective solution without sacrificing quality. This makes mono-material films an attractive choice for sustainable packaging and other applications.

What Are the Main Challenges in Producing Mono-Material Films?

Producing mono-material films is like building a house with a single brick; it’s challenging. You face hurdles in achieving ideal film coating and barrier properties, which are essential for protection and durability. Balancing these features while maintaining process efficiency is tough. You must innovate to develop materials that meet industry standards without complicating manufacturing, ensuring your films are sustainable, cost-effective, and functional—like a well-constructed home that withstands the test of time.

Are Mono-Material Films Suitable for All Packaging Applications?

Mono-material films aren’t suitable for all packaging applications due to application limitations, such as barrier properties and mechanical strength. You might find they work well for specific uses but fall short in others requiring advanced protection or durability. Additionally, while they improve environmental impact by easing recycling, their suitability depends on the particular packaging needs. Always assess your application’s requirements to determine if mono-material films are the right choice.

How Recyclable Are Mono-Material Films in Different Regions?

Mono-material films are generally more recyclable across regions, but their recyclability depends on local factors. In regions with robust recycling infrastructure, these films often meet material purity standards and are easily processed. Conversely, in areas with weaker infrastructure or strict standards, recycling can be limited. You should consider regional recycling practices, infrastructure quality, and material purity standards to determine how recyclable mono-material films truly are in your area.

What Innovations Are Emerging in Mono-Material Film Technology?

You’ll see innovations in mono-material film technology focusing on biodegradable alternatives, making packaging more eco-friendly. Manufacturers are also enhancing barrier properties to better protect products while maintaining recyclability. These advancements enable you to choose films that break down naturally and resist moisture or gases effectively. As a result, your packaging options become more sustainable without sacrificing performance, helping reduce environmental impact and support circular economy goals.

Conclusion

By choosing mono-material films, you simplify recycling, reduce waste, and promote sustainability. You support a circular economy, minimize environmental impact, and foster innovation. You make responsible choices, encourage eco-friendly practices, and contribute to a healthier planet. You embrace simplicity, promote efficiency, and drive positive change. Together, these actions create a future where sustainability isn’t just a goal but a reality—where your choices matter, your actions count, and your commitment makes a difference.