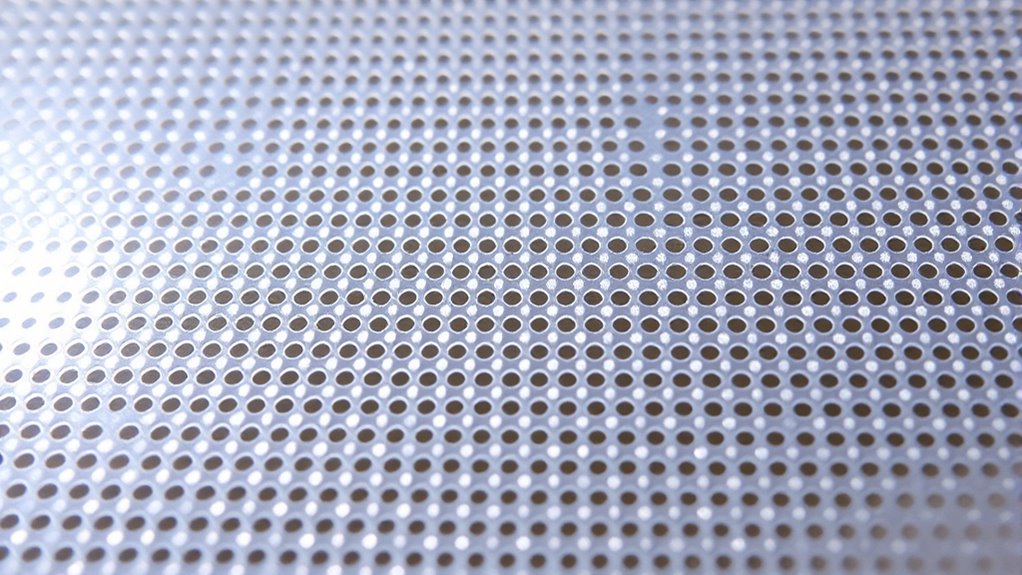

Laser perforated films help you enhance breathability and filtration by creating precise, uniform holes that regulate airflow without compromising barrier protection. This technology allows you to customize hole size, shape, and distribution, ensuring the most effective airflow while blocking dust, bacteria, or moisture. The process preserves the film’s strength and durability, making it ideal for sensitive packaging like electronics or food. Keep exploring to discover how this advanced method can boost your product quality and performance.

Key Takeaways

- Laser perforation allows precise control over hole size, shape, and distribution to optimize breathability.

- It maintains film strength and durability, suitable for demanding handling and environmental conditions.

- Produces uniform perforations, ensuring consistent airflow and filtration performance across large batches.

- Customizable designs balance airflow with barrier protection for sensitive products like electronics and food.

- Non-contact laser processing minimizes material waste and prevents damage, enhancing manufacturing efficiency.

Laser perforated films have revolutionized breathability in various packaging and protective applications. These films enable you to control airflow precisely, which is essential for preserving product quality and ensuring user comfort. When selecting a perforated film, two critical factors come into play: filtration efficiency and material durability. Understanding how laser perforation influences these elements helps you make smarter choices for your specific needs.

Filtration efficiency refers to how well the perforations allow air to pass through while blocking unwanted particles or contaminants. With laser perforation, you can fine-tune the size, shape, and distribution of the holes, giving you exact control over filtration performance. This precision means that you can design films that let in sufficient airflow for breathability without compromising the barrier against dust, bacteria, or moisture. For instance, if you’re packaging sensitive electronics or perishable food items, you want a film that maintains a controlled environment. Laser perforation allows you to optimize filtration efficiency, balancing breathability with protection.

Material durability is equally important. You need a film that withstands the rigors of handling, transportation, and environmental exposure without tearing or degrading. Laser perforation is a non-contact process that minimizes damage to the base material, preserving its strength and integrity. This technique ensures your perforated films maintain their durability over time, even under demanding conditions. Whether you’re using films for medical packaging, agricultural covers, or industrial applications, durability ensures your product remains protected and functional for its intended lifespan. Plus, laser perforation allows you to select materials with high tensile strength or flexibility, depending on your application, ensuring your perforated films can endure the stresses they encounter.

Another benefit of laser perforated films is their consistency. Unlike traditional methods, laser technology produces uniform perforations, guaranteeing predictable filtration efficiency and material durability across large production batches. This uniformity translates into reliable performance, reducing the risk of product failure or contamination. Additionally, because laser perforation is highly precise, it minimizes waste and material loss, making your process more efficient and cost-effective.

Frequently Asked Questions

How Do Laser Perforations Affect the Film’s Environmental Impact?

Laser perforations can improve the film’s environmental sustainability by reducing material use and enhancing breathability, which can lower energy needs during manufacturing. However, they may complicate recycling processes, as perforations can create small, difficult-to-separate pieces. You should consider these recycling implications carefully, as they might affect the overall eco-friendliness of the film. Strategically designed perforations can balance breathability benefits with minimal environmental impact.

Are Laser Perforated Films Suitable for Medical or Food Packaging?

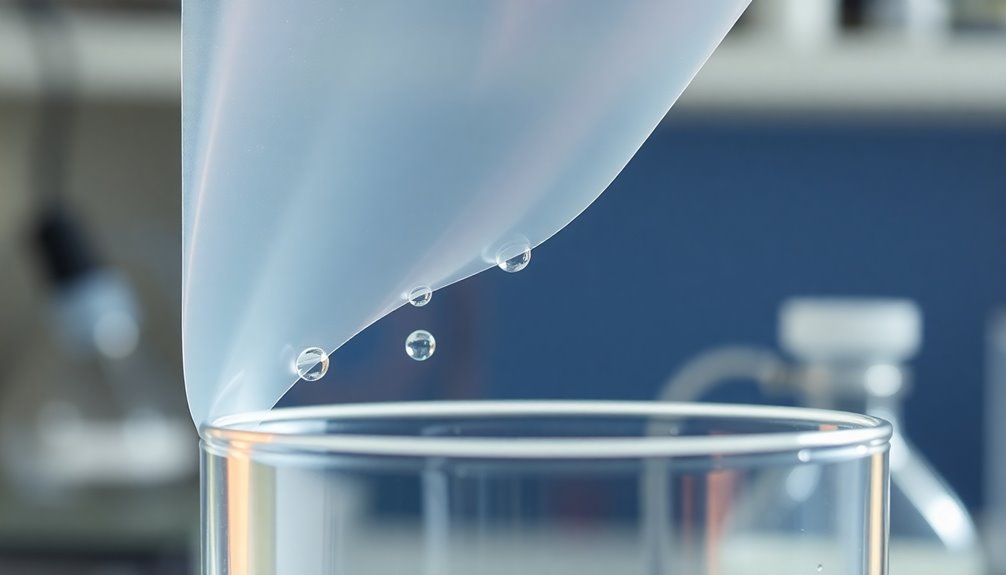

Think of laser perforated films as the gatekeepers of freshness, perfect for medical safety and food preservation. They’re highly suitable for medical packaging because they maintain sterile conditions while allowing breathability. For food packaging, these films help extend shelf life by letting gases escape, preventing spoilage. Their precise perforations confirm safety and freshness, making them an ideal choice for industries that prioritize both protection and breathability.

What Are the Cost Differences Between Laser Perforation and Traditional Methods?

You’ll find that laser perforation generally has higher manufacturing costs due to the equipment investment needed for precise, customizable perforations. Traditional methods, like mechanical or hot-needle perforation, often cost less upfront and are faster for large runs. However, laser perforation offers greater flexibility and precision, which can justify the higher costs in specialized applications. Overall, your choice depends on balancing initial investment with long-term benefits and production volume.

How Does Perforation Size Influence Moisture and Vapor Transmission?

Think of tiny windows in a building—smaller perforation sizes limit moisture and vapor transmission, much like small panes restrict airflow. Larger perforations increase permeability, allowing more moisture to escape, but too big can weaken the film. Perforation size directly influences material permeability and overall breathability. Higher perforation density with appropriately sized holes ensures ideal moisture release without compromising film strength, creating a balanced, breathable barrier.

Can Laser Perforated Films Be Customized for Specific Breathability Needs?

Yes, you can customize laser perforated films for specific breathability needs. By adjusting perforation patterns, such as size, shape, and spacing, you control moisture and vapor transmission rates. It is crucial to take material compatibility into account to guarantee the perforations don’t weaken the film. This customization allows you to attain ideal airflow while maintaining durability, tailoring the film precisely to your application’s requirements.

Conclusion

So, next time you’re struggling with sweaty clothes or stuffy gear, remember laser perforated films are here to save the day. Who knew tiny holes could make such a big difference? It’s almost like magic—except it’s science, with a dash of humor. So go ahead, breathe easy, stay cool, and thank those tiny laser beams for turning your sweaty nightmare into a breezy dream. Cheers to perforation perfection!