Multi-layer coextrusion film technology lets you create packaging with customized barrier, strength, and flexibility properties by layering different polymers. It helps protect perishable products, extends shelf life, and improves durability. However, recycling these multi-layer films can be tricky because of the varied materials involved, posing environmental challenges. If you keep exploring, you’ll discover innovative solutions that make these films both effective and more environmentally friendly.

Key Takeaways

- Multi-layer coextrusion creates films with tailored barrier, strength, and flexibility properties for specific packaging applications.

- It combines different polymers, such as EVOH and polyamide, to optimize performance and product protection.

- The technology enables enhanced barrier qualities, extending shelf life and reducing food waste.

- Recycling multilayer coextruded films is challenging due to diverse materials and layer separation complexities.

- Innovations focus on mono-material structures and compatible layers to improve recyclability and sustainability.

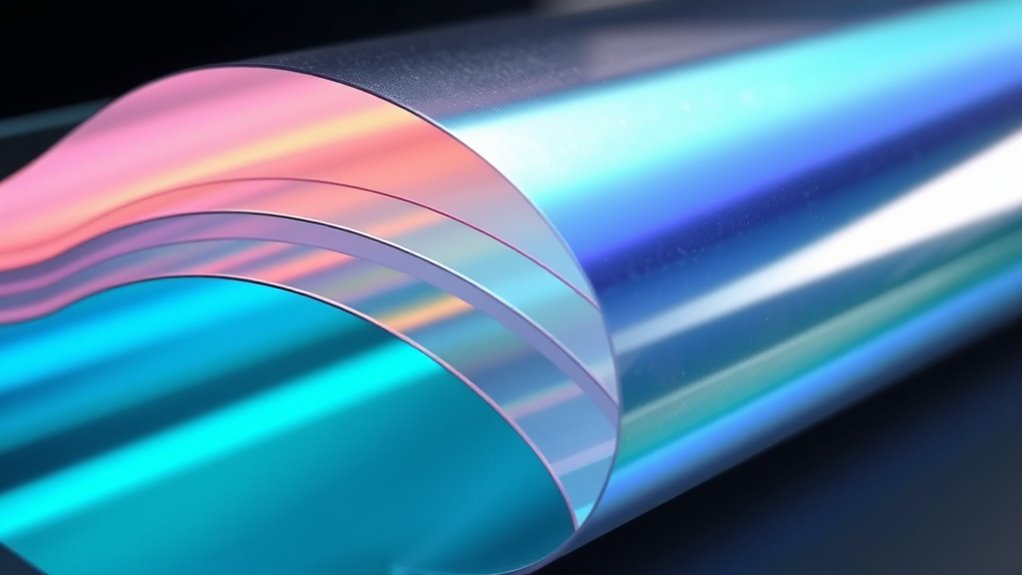

Multi-layer coextrusion film technology has revolutionized the packaging industry by allowing manufacturers to create films with enhanced properties tailored to specific applications. This approach involves layering different polymers to optimize performance, such as strength, flexibility, and barrier qualities. As you work with these films, you’ll notice that the multiple layers can considerably improve barrier properties, which are vital for preserving product freshness and extending shelf life. For instance, incorporating materials like ethylene vinyl alcohol (EVOH) or polyamide within the layers creates a formidable barrier against oxygen, moisture, and gases. This means your packaging can better protect perishable goods, reducing waste and maintaining quality during transportation and storage.

However, while the benefits are evident, you should also be aware of the recycling challenges associated with multi-layer coextrusion films. Because each layer may consist of different polymers, recycling becomes more complicated. Unlike single-material films, these multilayer structures often require specialized processes to separate and recycle the individual components effectively. If you’re aiming for sustainability, you might find that the recycling infrastructure for such complex films isn’t fully developed or widely accessible. As a result, many of these films end up in landfills or are incinerated, which raises environmental concerns. To address this, you might explore innovations like mono-material coextrusions, which maintain performance benefits while simplifying recyclability.

Despite these recycling challenges, advancements are ongoing. For example, some manufacturers are developing new adhesive layers or compatible polymers that allow for easier separation during recycling. Others are working toward designing films that can be mechanically or chemically recycled without losing their functional properties. If you’re involved in product design, you’ll want to consider the end-of-life impact early in the development process. Choosing materials with established recycling pathways or those that are compatible with existing waste management systems can make a substantial difference in minimizing environmental impact.

Frequently Asked Questions

How Does Coextrusion Impact the Recyclability of Films?

Coextrusion can make recycling more challenging because it creates films with multiple layers from different materials, leading to recycling challenges. You might find it hard to separate these layers efficiently, which hampers the recycling process. As a result, coextruded films often require specialized recycling methods or may end up in landfills. To improve recyclability, consider designing films with compatible materials or single-layer alternatives that simplify material separation.

What Are the Cost Differences Between Mono-Layer and Multi-Layer Films?

You’ll find that mono-layer films typically have lower manufacturing expenses and a simpler cost comparison, making them more budget-friendly initially. In contrast, multi-layer coextrusion films often cost more due to complex manufacturing processes and additional materials. While multi-layer films can offer enhanced properties, your choice depends on balancing higher production costs against performance benefits. Overall, mono-layer films usually present a more economical option for straightforward applications.

Can Coextrusion Films Be Customized for Specific Barrier Properties?

Yes, coextrusion films can be customized for specific barrier properties through film customization. You can select different resin layers to enhance barrier features like oxygen, moisture, or aroma protection. This allows you to tailor the film to your product’s needs, ensuring ideal preservation and shelf life. By customizing the barrier layers, you get a versatile solution that meets your unique packaging requirements efficiently and effectively.

What Are the Environmental Implications of Multi-Layer Coextrusion Films?

You should know that multi-layer coextrusion films can pose recycling challenges due to their complex structure, which makes them harder to process. This increases their environmental footprint, as they often end up in landfills or require specialized recycling methods. While they offer benefits like enhanced barrier properties, their environmental impact calls for improved recycling solutions and more sustainable material choices to reduce waste and ecological harm.

How Does Coextrusion Technology Influence Film Transparency and Clarity?

You’ll notice that coextrusion technology enhances film transparency and clarity by carefully controlling the film surface and layer adhesion. It allows you to produce films with smooth, transparent surfaces that look clear and appealing. By optimizing layer adhesion, the film maintains its clarity without cloudiness or haze. This technology guarantees consistent thickness and surface quality, giving you a product that’s visually attractive and suitable for packaging or display purposes.

Conclusion

With multi-layer coextrusion film technology, you access endless possibilities for creating superior packaging. It’s a game-changer that lets you tailor properties to suit your needs, boosting performance and efficiency. As the saying goes, the proof is in the pudding—this innovation truly delivers. By embracing this advanced technology, you stay ahead of the curve and turn challenges into opportunities. Don’t wait on the sidelines; immerse yourself and reap the benefits today.