Double wall corrugated boards are considerably stronger and more durable than single wall options. They feature multiple layers, providing better load capacity, impact resistance, and cushioning for fragile or heavy items. Single wall offers a lighter, more affordable option suitable for lightweight products. If you want to understand how these differences affect your packaging choices and discover which suits your needs best, continue exploring for more detailed insights.

Key Takeaways

- Double wall corrugated offers higher load capacity due to layered construction, providing superior strength and support.

- Its layered design distributes stress more evenly, enhancing impact resistance and durability against crushing.

- Double wall provides better stacking strength, reducing the risk of collapse under heavy loads.

- Single wall is less strong, suitable for lightweight items but more prone to damage under heavy or rough handling.

- Both types are recyclable, but double wall’s strength makes it more suitable for heavy-duty and fragile item packaging.

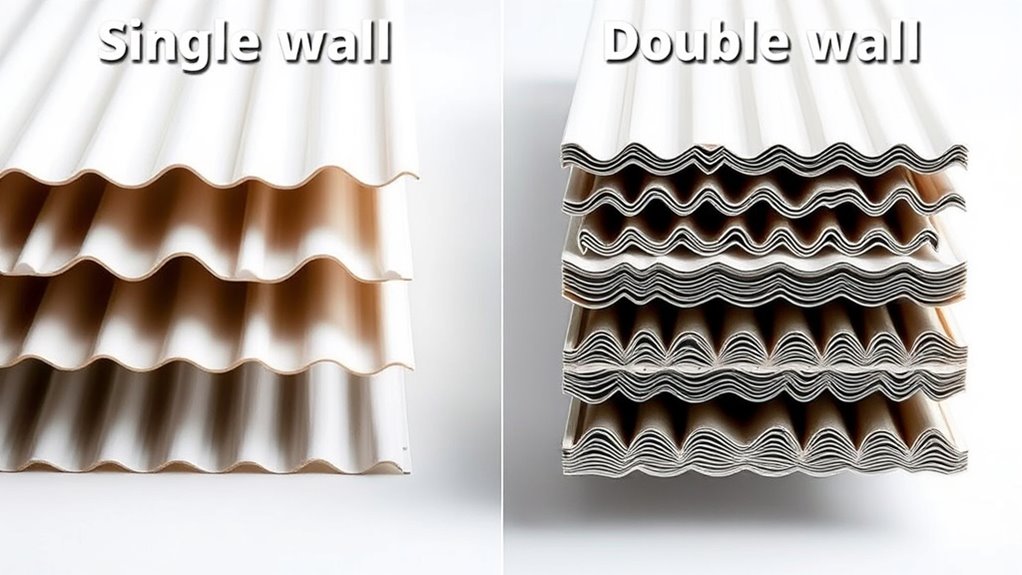

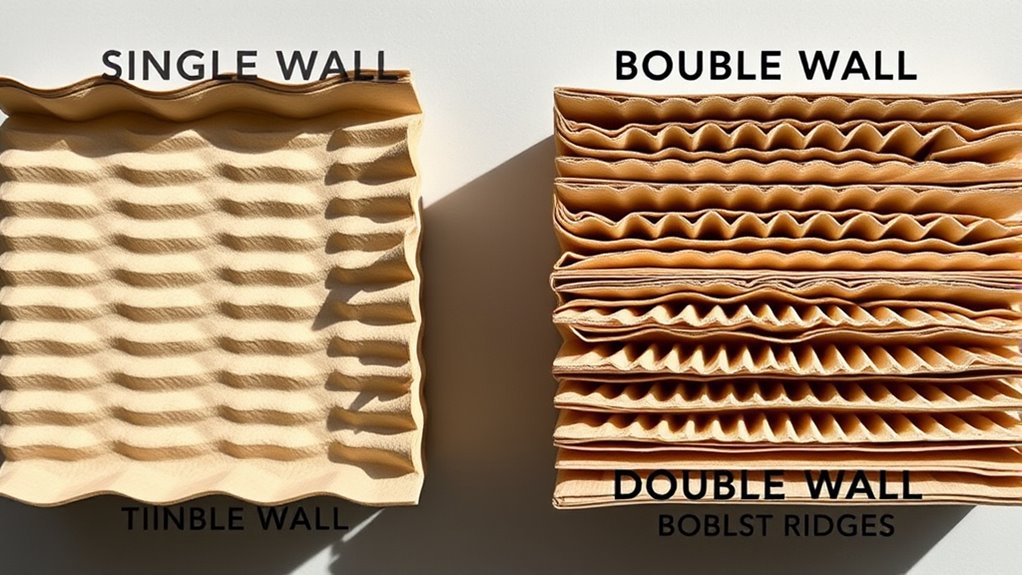

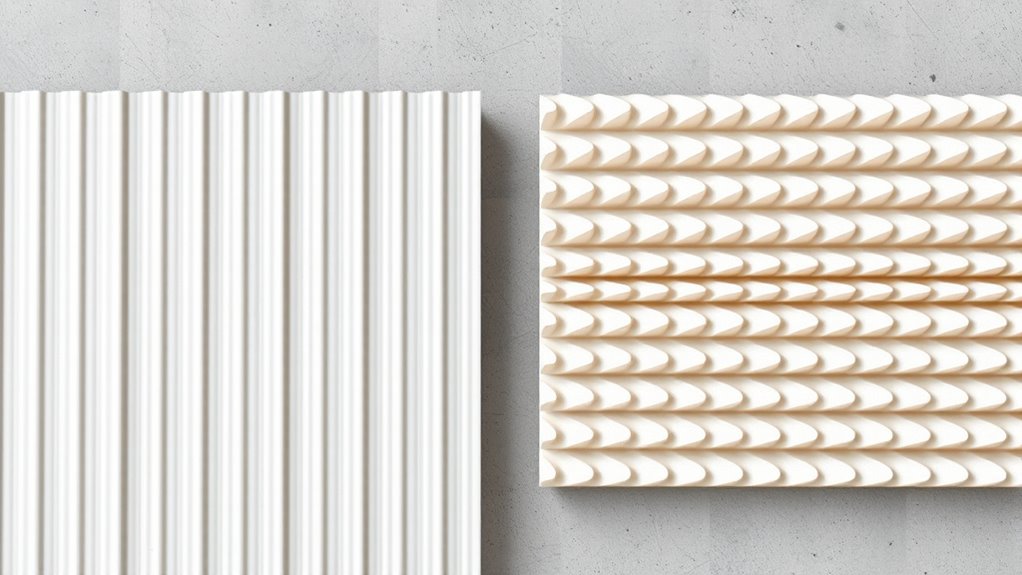

Material Composition and Construction Differences

Understanding the material composition and construction differences between single wall and double wall corrugated boards is essential for making informed choices. Single wall corrugated board features one layer of fluted medium glued between two linerboards, typically made from kraft or recycled paper. Its construction is straightforward, providing light to moderate strength. In contrast, double wall corrugated board has two layers of fluted medium, with an additional linerboard sandwiched between the flutes, increasing its thickness and durability. The construction differences mean double wall boards are heavier and more robust, suitable for heavier or more fragile items. The material composition and layered construction directly influence the board’s strength, weight, and protective qualities, helping you select the right option based on your packaging needs. Additionally, the layered design of double wall corrugated boards offers enhanced protective qualities, making them ideal for shipping sensitive items. The increased material thickness further contributes to their superior cushioning and impact resistance, which is critical for fragile contents. Moreover, double wall boards often have better insulation properties, helping to maintain temperature-sensitive products during transit.

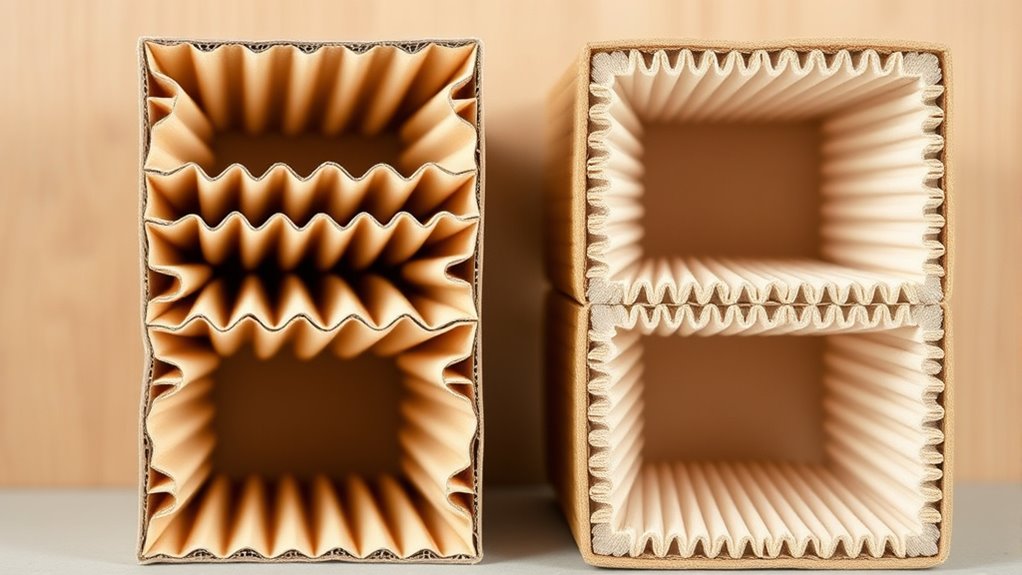

Load-Bearing Capacity and Structural Strength

When it comes to load-bearing capacity and structural strength, double wall corrugated boards outperform single wall options due to their layered construction. This design allows for greater stability and support under heavy loads. Additionally, double walls enhance thermal insulation, helping you keep temperatures consistent. They also provide better acoustic dampening, reducing noise transmission. Consider these points: 1. Double wall boards handle heavier weights without bending or buckling. 2. Their layered structure distributes stress more evenly. 3. Improved thermal insulation keeps your contents protected. 4. Enhanced acoustic dampening minimizes sound transfer, creating quieter environments. Layered construction also contributes to the overall strength and durability of double wall corrugated boards.

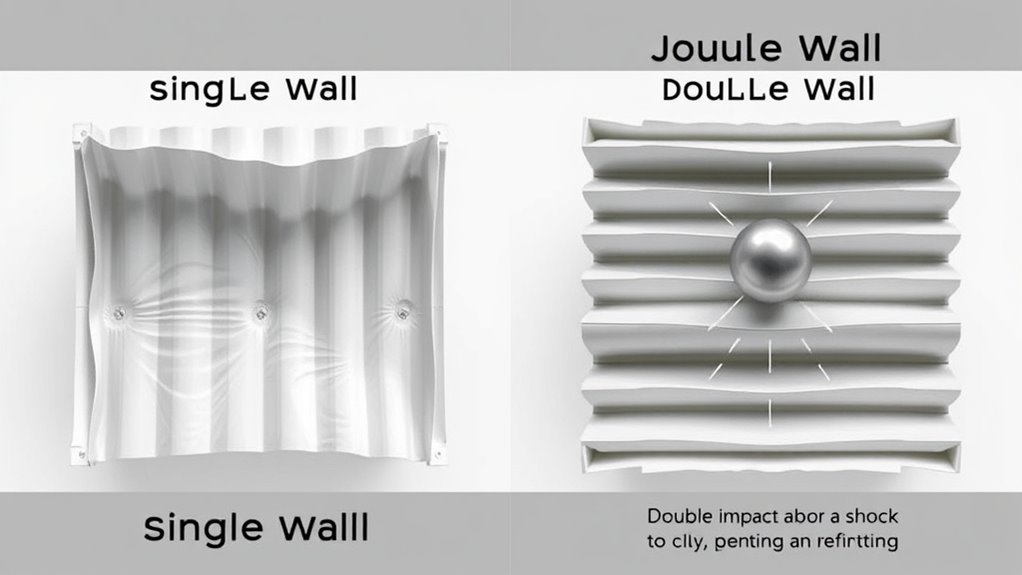

Impact Resistance and Shock Absorption

Double wall corrugated boards offer superior impact resistance and shock absorption compared to single wall options, making them ideal for protecting fragile or valuable contents during handling and transit. Their thicker construction absorbs shocks more effectively, reducing the risk of damage. You’ll notice that foam cushioning works better with double walls, enhancing protection against sudden impacts. Additionally, double wall panels often provide a smoother surface, boosting the aesthetic appeal of your packaging. This improved look can leave a positive impression on customers and clients. The combination of enhanced impact resistance and a more polished appearance makes double wall corrugated boards a preferred choice when safeguarding delicate items while maintaining a professional presentation. Moreover, the material strength of double walls contributes to greater durability and reliability during transportation, which is crucial for long-term product protection.

Suitability for Heavy-Duty Shipping Applications

Double wall corrugated boards are highly suitable for heavy-duty shipping applications because of their enhanced strength and durability. They can handle large, heavy loads and resist crushing during transit. Additionally, their superior insulation properties help protect sensitive items from temperature fluctuations, ensuring safe delivery. You’ll also notice an improved aesthetic appeal, making your packaging look more professional and sturdy. Proper planning of withdrawal strategies can optimize the use of packaging materials, especially when shipping sensitive or valuable items. Moreover, the structural integrity of double wall corrugated boards reduces the risk of damage even in rough handling situations. Incorporating material reinforcement techniques can further enhance their protective capabilities in demanding shipping environments. Furthermore, understanding the importance of legislative changes can assist in selecting the most compliant packaging options. Recognizing environmental considerations can guide the selection of eco-friendly materials, enhancing sustainability efforts. These features make double wall corrugated boards ideal for demanding shipping environments, giving you peace of mind that your goods are well-protected throughout transit.

Protection of Fragile Items During Transit

When protecting fragile items during transit, impact resistance is vital to prevent breakage. You need cushioning that absorbs shocks effectively, ensuring items stay intact. Additionally, the structural integrity of your packaging determines how well it withstands stress throughout shipping. Utilizing durable materials like double wall corrugated cardboard can significantly enhance packaging strength and provide better protection against impacts. Furthermore, the durability of corrugated material plays a crucial role in maintaining the safety of contents under various handling conditions. A higher impact absorption capacity can help minimize damage caused by sudden jolts or rough handling during transit. Incorporating resilience in packaging strategies can further improve the overall safety of your shipments, especially for high-value or delicate items. Considering Kia Tuning enhancements, such as upgraded suspension and protective modifications, can be analogous to choosing robust packaging materials to ensure vehicle safety during transport.

Impact Resistance Capabilities

While both single wall and double wall corrugated materials offer some impact protection, double wall corrugated is generally more effective at safeguarding fragile items during transit. Its thicker structure, combined with fiber reinforcement, absorbs shocks better. Additionally, double wall corrugated provides enhanced moisture resistance, preventing damage caused by humidity. To understand its impact capabilities:

- The extra layer distributes force evenly, reducing breakage risks.

- Fiber reinforcement adds rigidity, making it more resistant to crushing.

- The multi-layer design absorbs impacts from multiple directions.

- Moisture resistance helps preserve structural integrity during long hauls.

- Impact resistance is further strengthened by the use of high-quality fiber materials and precise manufacturing processes. Improved material durability ensures the packaging withstands tough handling conditions. Moreover, the structural integrity of double wall corrugated offers superior protection against compressive forces during stacking and transit, making it ideal for fragile, sensitive items, ensuring they arrive safely. Its superior impact resistance capabilities help minimize transit damages, protecting your goods better than single wall options.

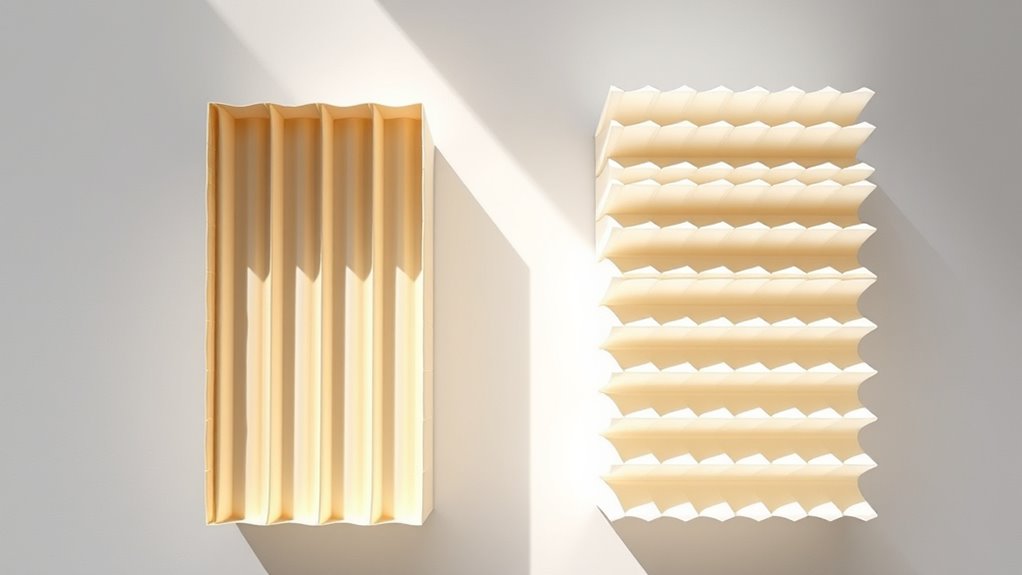

Cushioning Effectiveness

Building on its impact resistance, double wall corrugated also offers superior cushioning to protect fragile items during transit. Its thicker structure absorbs shocks better, minimizing damage. You can enhance this protection further by adding bubble wrap or foam padding inside the packaging. Bubble wrap conforms around delicate objects, providing a cushioned barrier against vibrations and impacts. Foam padding offers dense shock absorption, safeguarding items from sudden jolts. The combination of double wall corrugated and these cushioning materials creates a layered defense, reducing the risk of breakage. Incorporating additional cushioning materials such as foam inserts or air pillows can further improve shock absorption and overall protection. Utilizing packaging best practices can help ensure your items reach their destination intact and undamaged. This setup is especially beneficial for fragile or valuable items that require extra care during shipping. Overall, double wall corrugated enhances cushioning effectiveness, ensuring your items reach their destination intact and undamaged.

Structural Integrity Under Stress

Double wall corrugated provides enhanced structural integrity under stress, ensuring fragile items stay protected during transit. Its thicker layers resist crushing and deformation, which is vital when handling delicate goods. Consider these points:

- Temperature sensitivity: Double walls offer better insulation, reducing damage from temperature fluctuations that could compromise sensitive items.

- Aesthetic customization: They allow for more design flexibility, helping your packaging stand out while maintaining strength.

- Impact resistance: The double layer absorbs shocks better, preventing breakage during rough handling.

- Stacking strength: They support heavier loads, minimizing the risk of collapsing under pressure.

Cost Implications of Single vs. Double Wall Boards

Understanding the cost implications of single versus double wall corrugated boards is essential when choosing the right material for your packaging needs. A thorough cost analysis helps you compare material costs, manufacturing expenses, and transportation savings. Double wall boards typically cost more upfront due to increased material use, but they can reduce shipping costs by offering better protection, which may lower damage-related expenses. Single wall options usually have lower initial costs, making them suitable for lighter products. Your budget considerations should include not only the purchase price but also potential savings from reduced damage, handling, and storage. Balancing these factors ensures you select the most cost-effective solution that aligns with your packaging and shipping needs.

Environmental Impact and Recyclability

You should consider how recyclable each material is, as this impacts waste management and sustainability. Comparing the environmental footprints of single and double wall boards helps you understand their overall eco-friendliness. Additionally, their biodegradability and waste disposal options play a vital role in minimizing environmental harm.

Recyclability of Materials

Recyclability plays a crucial role in determining the environmental impact of corrugated materials. When comparing single wall and double wall corrugated options, understanding how easily they can be recycled helps you make eco-friendly choices. Here are key points to consider:

- Both materials are highly recyclable, reducing waste in landfills.

- The recyclability of materials depends on clean, uncontaminated paper fibers.

- Single wall corrugated is generally easier to recycle due to fewer layers.

- Double wall may require more processing, but remains recyclable, contributing to sustainability.

Environmental Footprint Comparison

Both single wall and double wall corrugated materials offer eco-friendly benefits through their recyclability, but their overall environmental footprints differ. Single wall tends to have faster biodegradation rates and simpler recycling processes, reducing environmental impact. Double wall, with its thicker structure, can pose recycling challenges due to layered materials and adhesives, which may slow down recycling efforts. Here’s a comparison:

| Aspect | Single Wall | Double Wall | Notes |

|---|---|---|---|

| Recyclability | Easier, more straightforward | More complex, potential challenges | Due to layered construction |

| Recycling Challenges | Lower | Higher | Adhesives and multiple layers complicate recycling |

| Biodegradation Rates | Faster | Slower | Thicker structure resists biodegradation |

Understanding these differences helps you choose packaging that minimizes environmental impact.

Biodegradability and Waste

While both single wall and double wall corrugated materials are designed to be eco-friendly, their biodegradability and waste management qualities vary markedly. You’ll find that:

- Single wall corrugated has higher biodegradability rates, breaking down faster in compost or natural environments.

- Double wall tends to take longer to decompose, making waste disposal more challenging if not recycled properly.

- Recycling methods differ: single wall is often easier to process with standard waste disposal methods, while double wall may require specialized facilities.

- Proper waste management can reduce environmental impact considerably, but the choice between materials influences how quickly waste is minimized and how efficiently it’s recycled.

Understanding these differences helps you choose packaging that aligns with sustainable waste disposal methods and reduces long-term environmental impact.

Customization Options for Different Packaging Needs

When selecting between single wall and double wall corrugated packaging, customization options play a crucial role in meeting your specific needs. You can tailor your packaging with various features, enhancing aesthetic versatility and functionality. Custom options include different printing designs, coatings, and structural modifications, making your packaging stand out and protect your products effectively. Here’s a quick overview:

| Feature | Single Wall Options | Double Wall Options |

|---|---|---|

| Printing | Full-color graphics | Custom branding |

| Coatings | Water-resistant | Matte or gloss finish |

| Structural Design | Variable flute size | Reinforced corners |

| Size Customization | Precise dimensions | Adjustable inserts |

| Aesthetic Versatility | Diverse print options | Enhanced visual appeal |

Common Industries and Use Cases for Each Type

Single wall corrugated packaging is ideal for lightweight, less fragile products across industries like retail, food service, and e-commerce, where cost-effectiveness and efficient shipping are priorities. In industrial applications and consumer packaging, it provides a reliable solution for everyday needs. You’ll find it commonly used in:

Ideal for lightweight products in retail, food service, and e-commerce shipping.

- Retail product boxes for clothing and accessories

- Food service containers for takeout and delivery

- E-commerce shipping cartons for lightweight goods

- Consumer packaging for electronics and small appliances

These applications benefit from single wall’s affordability and ease of handling, making it perfect for high-volume shipping. While double wall offers extra strength, single wall remains the go-to for lightweight, cost-sensitive products where efficiency is key.

Maintenance, Storage, and Handling Considerations

Proper maintenance, storage, and handling are essential to preserve the integrity of single wall corrugated packaging. To maximize storage flexibility, guarantee boxes are stacked properly and stored in a dry, stable environment to prevent damage. Avoid overloading or stacking boxes too high, which can compromise strength. When handling, prioritize ergonomics by using proper lifting techniques and equipment to reduce strain and prevent punctures or tears. Keep the packaging clean and inspect regularly for signs of wear or damage. Proper handling not only prolongs the lifespan of your boxes but also maintains their protective qualities. By managing storage and handling carefully, you guarantee your corrugated packaging remains reliable, safe, and ready for reuse or disposal.

Frequently Asked Questions

How Does Moisture Affect the Durability of Single and Double Wall Corrugated Boards?

Moisture impacts the durability of corrugated boards by causing moisture absorption and increasing humidity impact, which weaken the material. In single wall boards, moisture can easily penetrate, leading to warping and decreased strength. Double wall boards offer better resistance due to their layered structure, but prolonged exposure to high humidity can still compromise their integrity. Protecting both types from moisture extends their lifespan and maintains their strength.

Can Double Wall Corrugated Boards Be Recycled as Easily as Single Wall Types?

You might wonder if double wall corrugated boards are as easy to recycle as single wall types. While both face recycling challenges due to adhesives and coatings, double wall options often require more processing, making recycling slightly more complex. However, they remain eco-friendly options because they use recyclable materials. To improve recycling, look for manufacturers that produce more eco-friendly options and reduce contaminants in the recycling process.

What Are the Best Practices for Storing Different Types of Corrugated Boxes?

Storing corrugated boxes is like organizing a well-played symphony—every element matters. Keep storage temperature consistent and avoid extreme heat or cold, which can weaken the material. Confirm stacking stability by not overloading boxes and using proper support to prevent crushing. Store different types separately, with double wall boxes in dry, cool areas for added strength, and handle single wall boxes with care to maintain their integrity over time.

How Do Environmental Conditions Influence the Lifespan of Corrugated Packaging?

Environmental conditions play a vital role in your corrugated packaging’s lifespan. UV degradation from sunlight weakens the material over time, making it more prone to damage. Temperature fluctuations cause expansion and contraction, which can lead to warping or cracking. To maximize durability, store your boxes in cool, shaded areas and avoid prolonged exposure to direct sunlight. Proper handling and storage protect your packaging from environmental stressors, extending its useful life.

Are There Any Safety Considerations When Handling Heavy-Duty Double Wall Cartons?

Handling heavy-duty double wall cartons demands diligence and due care. You should observe handling safety by lifting with your legs, not your back, to prevent injuries. Be aware of the weight capacity to avoid overloading, which could cause collapse or accidents. Always secure the contents properly, and use appropriate equipment like forklifts or dollies when necessary. Taking these safety steps helps protect you and guarantees the integrity of the packaging.

Conclusion

Did you know double wall corrugated boxes are up to 70% stronger than single wall options? This makes them ideal for heavy-duty shipping and protecting fragile items. By choosing the right type, you guarantee your packages withstand tough conditions, reduce damage, and support sustainability. Whether you need durability or eco-friendliness, understanding these differences helps you make smarter packaging decisions that save money and protect your goods effectively.