Choosing between digital and offset printing depends on your packaging needs. If you want quick turnaround, customization, and lower initial costs for small runs, digital printing is ideal. For large volume, high-quality, and cost-efficient production, offset printing is better. Each method offers different benefits in speed, quality, and sustainability. To identify the best approach for your project, consider factors like design complexity, volume, and timeline—more insights follow.

Key Takeaways

- Digital printing is ideal for short runs, customization, and quick turnaround, while offset is best for large-volume, high-quality production.

- Offset offers sharper images and finer detail, suitable for high-end, bulk packaging needs.

- Digital printing has lower initial costs and eco-friendly benefits, making it suitable for small batches and sustainable practices.

- Offset provides consistent color and durability for long-term, high-volume packaging, whereas digital excels in personalized and variable designs.

- Choose digital for flexibility and speed, and offset for cost-effective, large-scale, high-quality packaging production.

Overview of Digital Printing Techniques for Packaging

Have you ever wondered how digital printing transforms packaging? Digital printing offers a versatile, efficient approach that enhances packaging innovation. Unlike traditional methods, it allows you to produce high-quality designs directly from digital files, eliminating the need for plates. This process is perfect for short runs, rapid prototyping, and customization, making it ideal for brands seeking flexibility. Digital printing uses inkjet or toner-based technologies to deposit colors precisely onto various materials. It enables vibrant, sharp images with quick turnaround times, reducing costs and waste. As a result, digital printing is revolutionizing packaging by making it more adaptable to market trends and consumer demands. This technique empowers you to create striking, personalized packaging that stands out on shelves. Additionally, halal-friendly printing practices ensure that packaging complies with cultural and religious standards, expanding market reach. Incorporating digital printing technology also allows for easy updates and seasonal variations, keeping your packaging fresh and relevant.

Understanding Offset Printing Methods and Processes

Offset printing remains a widely used method in packaging due to its ability to produce high-quality, consistent images at large volumes. The process, known as offset lithography, involves transferring ink from printing plates to a rubber blanket before printing onto the packaging material. You start with creating precise printing plates, which carry the image to be printed. These plates are usually made of metal and are processed to include the design. When the press runs, ink is applied to the plates, which then transfer the image onto the rubber blanket. The blanket subsequently presses the image onto the packaging substrate. This method guarantees sharp detail, color accuracy, and uniformity, making offset lithography ideal for bulk packaging production where quality and consistency are critical. Additionally, the use of necessary cookies and other categories helps ensure quality control and process monitoring during printing. The process also benefits from advanced registration techniques, which help maintain alignment and precision throughout high-volume runs. Moreover, offset printing can accommodate a wide range of color processes, ensuring vibrant and accurate reproduction of brand colors and designs. Furthermore, the ability to handle various substrate types allows for versatility in packaging applications.

Cost Implications for Small and Large Packaging Runs

When choosing a printing method, understanding the cost differences between small and large packaging runs is essential. Digital printing offers low setup costs, making it ideal for small batches, but costs can rise with volume. Offset printing requires higher initial investment but becomes more cost-effective for large runs due to its economies of scale. Your pricing strategies depend on run size and market trends. Consider this table:

| Run Size | Cost per Unit | Best For |

|---|---|---|

| Small Runs | Higher due to setup costs | Custom, limited editions |

| Large Runs | Lower per unit, scalable | Mass production |

| Medium Runs | Balance of quality and cost | Moderate demand |

Understanding these implications helps you optimize costs and adapt to market trends. Additionally, as AI continues to revolutionize industries, leveraging AI-driven solutions can further enhance production efficiency and cost management. Incorporating cost analysis tools can also assist in making informed decisions based on detailed production data. Recognizing the scale of production is vital for selecting the most cost-effective printing method for your specific needs, especially when considering the long-term cost savings associated with different approaches. Moreover, evaluating print quality requirements can help determine the most suitable technology for your packaging needs.

Speed and Turnaround Times in Digital and Offset Printing

Speed and turnaround times can considerably influence your choice of printing method, especially when deadlines are tight. Digital printing offers rapid production speed, often producing small runs quickly without extensive setup, which boosts your turnaround efficiency. You can expect shorter lead times, making it ideal for quick-turn projects or on-demand prints. Additionally, understanding the essential oils involved in print production can help optimize the overall process and final quality. Digital printing technology utilizes digital files, enabling faster adjustments and proofs, which further streamlines the workflow. The absence of plate creation in digital printing significantly reduces setup time, making it more suitable for fast-paced projects. Offset printing, however, typically involves longer setup times due to plate creation, which can slow down overall turnaround, especially for small runs. But once established, offset can handle large quantities efficiently and cost-effectively. If you need rapid delivery for a limited quantity, digital printing is usually the better option. For large orders where speed is less critical, offset’s steady production pace can still meet your deadlines while maintaining cost advantages. Considering the print process and its impact on delivery timelines can help you choose the most suitable method for your project.

Quality and Resolution Differences Between the Two Methods

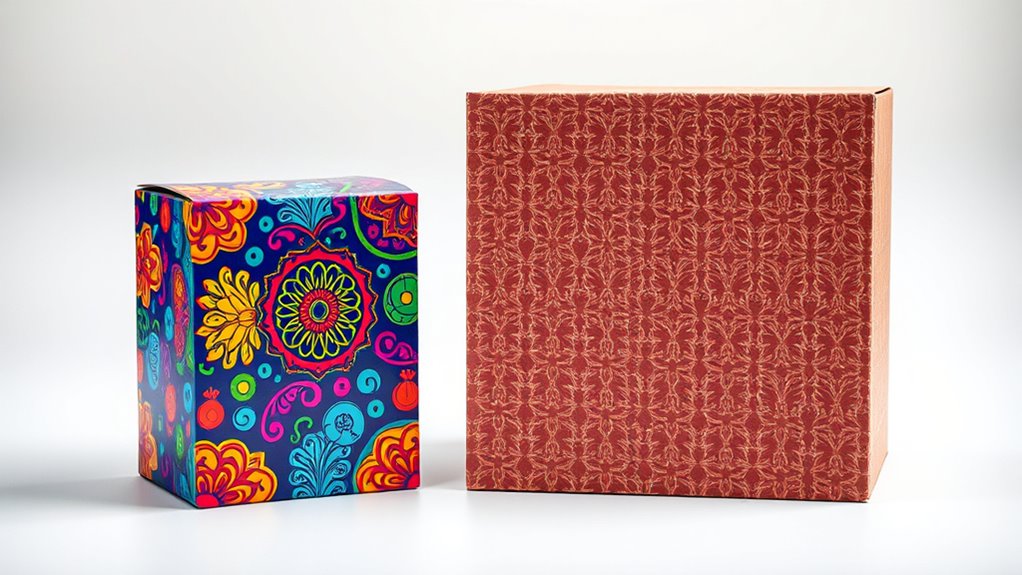

When comparing digital and offset printing, you’ll notice differences in color fidelity and depth, which can impact the vibrancy of your images. Image sharpness and detail also vary, with offset often producing crisper results on larger runs. Understanding these quality aspects helps you choose the best method for your project’s visual impact.

Color Fidelity and Depth

Digital and offset printing differ markedly in their ability to reproduce colors accurately and create depth. Digital color tends to be vibrant and consistent, making it ideal for short runs or variable data. Offset printing, on the other hand, offers richer color fidelity and smoother gradients due to its precise ink application. The ink depth in offset presses allows for more nuanced shading, resulting in a sense of depth that enhances packaging appeal. Digital printing’s ink depth is more limited, which can sometimes compromise color richness and depth, especially in complex designs. If achieving true color accuracy and a sense of depth is your priority, offset printing generally provides superior results. Additionally, HEPA filtration technology in air purifiers can help maintain a cleaner environment, which might be beneficial during packaging production. Properly managing print quality standards ensures consistent results, especially when aiming for high-fidelity color and depth. Moreover, understanding the residency requirements for different jurisdictions can influence production scheduling and logistics, ensuring compliance and efficiency. Maintaining optimal print calibration is essential for consistent color fidelity and depth across large production runs. Additionally, advanced color management techniques can further improve the consistency and accuracy of color reproduction in offset printing. However, digital offers quick turnaround and flexibility, which may suit other project needs better.

Image Sharpness and Detail

Offset printing typically produces sharper images with finer detail because of its high-resolution plates and precise ink application. This advanced printing technology captures intricate packaging design elements more accurately, resulting in crisp lines and clear images. With offset, you’ll notice better reproduction of small text and detailed graphics, making it ideal for complex packaging. If your priority is high image quality and precision, offset’s ability to produce consistently sharp, detailed results makes it the superior choice. For packaging where visual clarity and fine detail are *essential*, understanding the differences in image sharpness will help you select the best printing method. Additionally, offset printing is well-suited for maintaining consistent color accuracy across large production runs, especially when combined with high-quality inks, ensuring the final product meets strict visual standards.

Color Accuracy and Consistency in Packaging Production

Ensuring color matching precision is essential for your packaging, especially when consistency over multiple batches matters. Digital and offset printing each handle color accuracy differently, affecting how reliably your colors stay uniform. Compatibility with Pantone colors also plays a key role in achieving the exact shades you need.

Color Matching Precision

Achieving precise color matching in packaging production is essential for maintaining brand consistency and customer trust. Proper print color calibration guarantees that the colors you see on your screen translate accurately onto the final product. Digital printing often offers tighter control over ink color matching, allowing you to fine-tune colors easily and achieve consistent results across multiple prints. Offset printing, on the other hand, relies heavily on precise ink color matching processes, which can be more complex but yield high-quality, vibrant colors. Both methods demand careful calibration to prevent color deviations. Ultimately, your choice depends on your production needs; but regardless of the method, focusing on accurate print color calibration is key to ensuring your packaging consistently reflects your brand’s true colors.

Consistency Over Batches

Maintaining consistent color accuracy across multiple batches is essential for preserving your brand’s visual integrity. Achieving batch uniformity guarantees that every printed piece looks identical, reinforcing your brand identity. Digital printing often offers superior print consistency, making it easier to maintain uniformity across short runs or multiple batches. Offset printing, while excellent for large quantities, can sometimes introduce slight variations between batches, affecting overall consistency. To ensure your packaging remains cohesive, you need reliable color management and quality control processes, regardless of the printing method. Consistent color reproduction helps build customer trust and strengthens brand recognition. By prioritizing print consistency, you guarantee that each batch meets your standards, keeping your packaging visually appealing and professionally aligned with your brand’s image.

Pantone Compatibility

Pantone compatibility plays a crucial role in ensuring color accuracy and consistency across your packaging production. Achieving precise color matching requires reliable Pantone standards that translate accurately across different printing methods. When materials are compatible with Pantone colors, your designs stay true from concept to final product, avoiding disappointing shifts. Without this compatibility, colors can look mismatched, damaging your brand’s reputation.

Key benefits include:

- Confidence in consistent color matching across batches

- Seamless communication with suppliers about exact hues

- Reduced waste caused by color discrepancies

- Enhanced material compatibility for true color reproduction

Material Compatibility and Printing Versatility

When choosing between digital and offset printing, understanding their material compatibility and versatility is essential. Digital printing offers excellent material flexibility, letting you print on a wide range of substrates like plastics, labels, and uncoated papers. Its surface adhesion is strong on these diverse surfaces, ensuring vibrant, crisp images. Offset printing, however, excels with traditional materials such as coated papers and cardboard, providing consistent color quality and sharp detail. It’s less adaptable with unusual or textured surfaces. Your choice depends on the packaging material you plan to use; digital printing is ideal for short runs and varied substrates, while offset suits large quantities of uniform materials. Knowing each method’s material compatibility helps you select the best printing process for your packaging needs.

Environmental Impact and Sustainability Considerations

You should consider how each printing method impacts the environment through resource use and waste. Digital printing generally consumes less ink and produces less waste, while offset printing often requires more materials and generates more scrap. Exploring eco-friendly ink options and effective waste management strategies can help reduce your overall environmental footprint.

Resource Consumption Differences

Although both digital and offset printing consume resources, their environmental impacts differ markedly. Digital printing generally uses less energy per print, reducing overall energy consumption, but can require more frequent maintenance. Offset printing often demands higher energy input, especially for large runs. Water usage also varies: offset presses rely heavily on water-based processes, increasing water consumption, while digital presses typically use minimal water.

- You can lower your environmental footprint by choosing digital for smaller batches, saving energy and water.

- Offset printing’s higher resource use translates into greater environmental strain over time.

- Reducing energy consumption means less greenhouse gas emissions, helping fight climate change.

- Minimizing water use supports conservation efforts and preserves crucial freshwater sources.

Understanding these differences helps you make sustainable choices for packaging.

Waste Management Strategies

Effective waste management is vital to minimizing the environmental impact of both digital and offset printing processes. You can implement recycling initiatives to properly dispose of paper waste, inks, and other materials, reducing landfill contributions. Waste reduction techniques, such as optimizing print runs and adjusting ink usage, help minimize excess materials and energy consumption. Digital printing often produces less waste due to on-demand production, while offset printing benefits from precise registration that reduces errors. By adopting these strategies, you guarantee your printing operations are more sustainable and eco-friendly. Prioritizing waste management not only lowers environmental impact but also enhances your company’s reputation for responsible manufacturing. Staying committed to recycling initiatives and waste reduction techniques is essential for greener packaging solutions.

Eco-friendly Ink Options

Eco-friendly ink options play a crucial role in reducing the environmental footprint of printing processes. By choosing plant-based inks and biodegradable dyes, you can minimize harmful emissions and waste. These alternatives are made from renewable resources, helping you support sustainability efforts and protect natural ecosystems. Using eco-conscious inks not only benefits the planet but also enhances your brand’s reputation as environmentally responsible. Imagine creating packaging that appeals to eco-aware consumers and reduces your carbon footprint.

- Feel proud knowing your choices promote a healthier planet.

- Inspire customers to make greener decisions.

- Reduce reliance on toxic, petroleum-based inks.

- Contribute to a sustainable future for generations to come.

Suitability for Customization and Special Effects

When it comes to customization and special effects, digital printing clearly outperforms offset printing because it allows for greater flexibility and intricate detail. With digital printing, you can easily incorporate a wide range of customization options, including variable data, colors, and designs tailored to each package. This makes it ideal for limited editions or personalized branding. Additionally, digital presses excel at creating special effects like metallic finishes, gloss, matte textures, or spot UV coatings, which can markedly enhance your packaging’s visual appeal. Offset printing, while excellent for high-volume, consistent prints, is less adaptable for complex customization and special effects due to setup constraints. Overall, digital printing offers the versatility necessary for eye-catching, customized packaging that stands out on the shelves.

Making the Right Choice: Factors to Consider for Your Packaging Needs

Choosing between digital and offset printing hinges on several key factors that align with your specific packaging needs. Consider the level of packaging durability required—if your packaging needs to withstand rough handling or environmental factors, offset printing often offers superior durability. Design flexibility is also vital; digital printing allows for quick changes and intricate designs, ideal for limited runs or personalization. Think about production volume: offset is cost-effective for large quantities, while digital is better for small batches. Finally, assess your timeline—digital printing provides faster turnaround times. By weighing these factors, you guarantee your packaging not only looks great but also performs reliably.

Choosing digital or offset printing depends on durability, design flexibility, volume, and timeline needs.

- Feel confident in your choice, knowing your packaging will impress and endure.

- Achieve stunning, flexible designs tailored to your brand.

- Save time with quick production options.

- Guarantee your packaging meets durability standards effortlessly.

Frequently Asked Questions

Which Printing Method Offers Better Long-Term Durability for Packaging?

You want to know which printing method offers better long-term durability for packaging. Digital printing often provides excellent ink longevity and vibrant colors, but offset printing tends to deliver superior scratch resistance and durability over time. If your packaging needs to withstand handling and environmental factors, offset printing is usually the better choice. It guarantees your packaging maintains its quality longer, keeping your brand looking professional and appealing on shelves.

How Do Digital and Offset Printing Compare for Small Batch Runs?

Did you know that over 60% of small businesses prefer digital printing for their packaging needs? For small batch runs, digital printing shines with faster print speed and minimal setup costs, making it ideal for limited quantities. You can get quick turnaround times without the expense of extensive setup, unlike offset printing. So, if you’re doing a small run, digital printing offers efficiency and affordability, saving you both time and money.

Are There Specific Packaging Materials Incompatible With Either Printing Method?

You might wonder if certain packaging materials are incompatible with specific printing methods. Incompatible substrates or material limitations can affect your choice, as some materials like certain plastics or textured surfaces may not work well with digital or offset printing. Digital printing often handles smaller, flexible, or thin substrates better, while offset requires smoother, heavier materials. Always check the material compatibility to ensure your packaging looks great and prints flawlessly.

Which Printing Technique Has a Lower Overall Environmental Footprint?

Think of eco-friendliness as a race; digital printing often leads because it produces less waste and uses fewer resources. You’ll find digital methods typically have a smaller carbon footprint, making them more sustainable for packaging. For example, digital printing’s on-demand nature reduces excess inventory, aligning with eco-conscious goals. If sustainability matters most to you, digital printing generally offers a greener choice, supporting your efforts to minimize environmental impact.

Can Digital Printing Achieve the Same Color Vibrancy as Offset?

You can achieve impressive color vibrancy with digital printing, thanks to advances in ink technology. While offset printing still often delivers superior color accuracy and richer hues, digital methods are catching up, offering vibrant results suitable for many packaging needs. With the right ink choices and color management, digital printing can provide eye-catching, high-quality packaging that rivals offset in vibrancy, making it a versatile option for various projects.

Conclusion

Choosing between digital and offset printing is like picking the perfect brush for your masterpiece — it depends on your needs. Digital offers speed and customization, while offset delivers top-tier quality for large runs. Consider your budget, timeline, and design complexity. Ultimately, the right choice transforms your packaging from mere protection to a mesmerizing experience. So, weigh your options wisely — because your packaging deserves to stand out like a star in the night sky.