When looking at kraft paper, you'll find key indicators that showcase its quality and performance. These include color consistency, which should be 99% uniform across batches, and folding endurance, important for packaging resilience. You'll also want to reflect on tensile strength, as a higher value means better resistance to tearing. Additionally, moisture content affects its durability. Kraft paper is eco-friendly and recyclable, making it a popular choice. By understanding these indicators, you can determine the best kraft paper for your needs and discover additional insights that can enhance your selection process.

Key Takeaways

- Color Consistency: Kraft paper should maintain 99% uniformity across batches to ensure quality assurance.

- Folding Endurance: This indicator measures resistance to repeated folding, essential for effective packaging.

- Tensile Strength: Indicates the paper's ability to withstand force before tearing, crucial for durability in heavy-duty applications.

- Phosphor Usage: Regulated levels of fluorescent agents are important for safety in food packaging applications.

- Compression Resistance: Kraft paper should effectively endure pressure without compromising structural integrity, varying by basis weight.

Definition and Characteristics

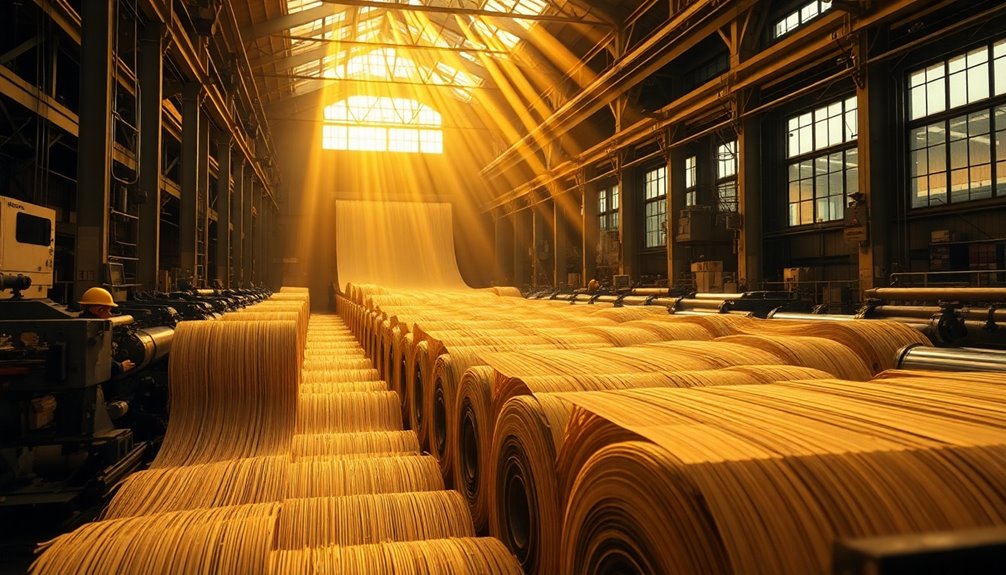

When you think of kraft paper, imagine a strong and versatile material that's perfect for all your packaging needs. This coarse material is made primarily from wood pulp through the sulfate pulping process, resulting in a robust product that's indispensable in various applications.

You'll find two main types: unbleached kraft, which is brown and maintains its natural fibers, and bleached kraft, which is white and offers enhanced printability.

One of the standout characteristics of kraft paper is its impressive tensile strength, markedly higher than that of standard paper. This strength makes it ideal for heavy-duty uses like multiwall bags and shipping sacks.

Kraft paper comes in various basis weights, typically ranging from 18 to 200 lbs, with common options between 25 and 80 lbs.

Moreover, kraft paper isn't just strong; it's also environmentally friendly. Being recyclable and produced from renewable resources, it aligns well with sustainability initiatives in packaging.

Strength and Durability

When considering kraft paper, you'll find its impressive tensile strength is a key factor in its ability to handle heavy loads without tearing.

You'll also want to look at its compression resistance, which guarantees durability even under pressure.

Plus, kraft paper holds up well in various conditions, making it a reliable choice for your packaging needs.

Tensile Strength Properties

Kraft paper boasts impressive tensile strength properties that make it a go-to choice for various heavy-duty applications.

Natural kraft typically shows a tensile strength range of 25-35 MPa, perfect for multiwall bags and shipping sacks. If you need even more strength, consider Super-Performance Kraft (SPK), which is 10-15% stronger than traditional natural kraft. This means you can achieve the same strength while using less material, enhancing durability.

One of the key aspects of natural kraft is its machine direction (MD) tensile strength, which is considerably higher than its cross direction (CD) strength. This characteristic allows the paper to withstand high stress during transport and handling effectively.

Additionally, kraft paper's excellent tear resistance complements its tensile strength, ensuring it won't rip or fail under heavy loads, a critical factor for packaging applications.

Kraft paper also boasts stretch values of less than 2% in the machine direction. This low stretch indicates that it maintains its integrity under tension without excessive elongation, further contributing to its reputation for durability.

To summarize, kraft paper is an ideal choice for those seeking high tensile strength and reliability in their packaging solutions.

Compression Resistance Factors

High tensile strength isn't the only property that makes kraft paper a top choice for packaging; its impressive compression resistance plays a significant role in its durability.

The compression strength of kraft paper varies depending on several factors, including its basis weight. Heavier grades typically provide greater load-bearing capacity, making them ideal for heavy-duty applications like multiwall bags.

To guarantee peak performance, consider these factors:

- Moisture Content: Keeping moisture levels between 6-8% enhances the paper's structural integrity.

- Manufacturing Process: The removal of lignin during production contributes to kraft paper's exceptional durability and resistance to deformation under pressure.

- Environmental Factors: Humidity and temperature can impact compression resistance, so monitor storage conditions to prevent strength loss.

- Basis Weight: Selecting the appropriate basis weight is vital for achieving desired compression strength.

Durability Under Conditions

Under varying environmental conditions, the strength and durability of kraft paper become vital for its performance in packaging. Kraft paper boasts impressive tensile strength, typically ranging from 20,000 to 30,000 psi, making it a go-to choice for heavy-duty packaging applications.

Its moisture resistance varies by type; for instance, wet strength kraft retains about one-third of its dry tensile strength in humid conditions, ensuring durability even in challenging environments.

When you need flexibility, extensible kraft is your best bet, as it offers a machine-direction stretch of 2-4%, allowing it to handle stress without tearing. This feature is particularly essential for multiwall sacks.

For enhanced performance, super-performance kraft (SPK) provides a remarkable 10-15% increase in strength compared to traditional natural kraft, enabling reduced paper usage while maintaining durability.

Additionally, the folding endurance of kraft paper often exceeds 50 folds, demonstrating its toughness and ability to withstand frequent handling without damage.

All these attributes make kraft paper an excellent choice for various packaging applications, ensuring that your products remain secure and intact regardless of the conditions.

Environmental Benefits

When you choose kraft paper, you're making a positive impact on the environment. This eco-friendly option stands out for several reasons that contribute to its sustainability.

Kraft paper is fully recyclable and reusable, greatly reducing landfill waste compared to traditional plastic packaging materials.

Here are some key environmental benefits of kraft paper:

- Sustainable Forestry: The production of kraft paper relies on wood pulp sourced from responsibly managed forests, promoting biodiversity.

- Lower Carbon Footprint: Compared to plastic and glass packaging, kraft paper has a lower carbon footprint, making it a better choice for the planet.

- Reduced Emissions: The manufacturing process utilizes chlorine dioxide and oxygen bleaching, which generates fewer harmful emissions than traditional chlorine methods.

- Biodegradable: Kraft paper decomposes naturally over time, contributing to soil health and reducing long-term environmental impact.

Food Packaging Applications

Kraft paper's environmental benefits make it an excellent choice for food packaging applications. Its moisture-proof and waterproof qualities are perfect for protecting bakery items, meats, and dairy products. You'll appreciate how greaseproof paper and glassine kraft papers resist grease and oil, maintaining food quality while being a cost-effective solution compared to plastic or glass.

Here's how kraft paper stands out in food packaging:

| Feature | Benefit |

|---|---|

| Non-toxicity | Safe for food contact |

| Barrier properties | Preserves freshness and shelf life |

| Regulatory standards | Meets safety guidelines |

Laminated kraft paper enhances barrier properties against gases and moisture, extending the shelf life of various food products. As consumer demand for sustainable options rises, choosing kraft paper not only aligns with eco-friendly practices but also guarantees compliance with safety standards. By opting for kraft paper, you're making a conscious decision to support food packaging that's effective, safe, and environmentally responsible.

Color Variations and Quality

Color variations in kraft paper play a significant role in determining its quality and suitability for different applications.

You'll find that kraft paper comes in two primary color variations: brown and white. The brown variations are unbleached, making them stronger, while the white variations are bleached to enhance print quality and cleanliness. The differences in color stem from the raw materials used and the specific production processes involved.

To guarantee you're selecting the right kraft paper, consider these key indicators:

- Color consistency: Manufacturers aim for 99% uniformity across batches to maintain quality and brand integrity.

- Folding endurance: This measures the paper's ability to withstand repeated folding without breaking, essential for various packaging applications.

- Tensile strength: A critical indicator of how much force the paper can withstand before tearing, guaranteeing durability in packaging.

- Phosphor usage: High fluorescent agent content in white kraft paper can pose risks, leading to strict regulations, especially in food packaging.

Understanding these aspects will help you assess the quality of kraft paper for your specific needs.

Market Trends and Consumer Preferences

As you explore the kraft paper market, you'll notice a strong shift towards eco-friendly packaging, with many consumers willing to pay extra for sustainable options.

Customization and aesthetic appeal are also becoming vital factors, as brands look to differentiate themselves in a crowded marketplace.

Understanding these trends can help you better cater to the evolving preferences of your target audience.

Eco-Friendly Packaging Demand

There's no denying that the demand for eco-friendly packaging has skyrocketed in recent years, with a significant number of consumers actively seeking sustainable options.

As you explore this market trend, you'll find that kraft paper stands out due to its biodegradable nature and impressive performance in recycling. In fact, around 74% of shoppers are willing to pay more for environmentally friendly choices, and the U.S. recycling rate for kraft paper bags was about 37.6% as of 2008.

This shift towards sustainable materials is reshaping the packaging landscape, particularly in e-commerce, where businesses are looking for eco-friendly shipping solutions that resonate with their customers' values.

Key indicators of this trend include:

- Increased consumer awareness about environmental practices

- A projected sustainable packaging market of $500 billion by 2028

- Enhanced brand loyalty, as 66% of consumers consider a brand's environmental practices

- The growing preference for biodegradable options over plastic alternatives

Customization and Aesthetics

The rise of customization and aesthetics in packaging is transforming consumer expectations, especially in the domain of eco-friendly options like kraft paper.

You'll notice that the natural brown color of kraft paper appeals to many, evoking a warm, rustic aesthetic that resonates with those seeking nostalgic and environmentally responsible packaging options.

As you explore customization possibilities, printed designs and personalized branding greatly enhance the visual appeal of kraft paper, making it a top choice for attracting attention on store shelves.

Today's consumers prefer sustainably sourced and recyclable materials, aligning perfectly with kraft paper's eco-friendly attributes.

The versatility of kraft paper allows for various finishes, from glossy to matte, catering to diverse consumer tastes and enhancing product presentation.

This flexibility means you can create unique packaging options that stand out in a crowded market.

Studies suggest that attractive packaging, particularly custom kraft paper designs, can boost brand recognition and consumer engagement, ultimately leading to higher sales.

Adapting to these market trends not only meets consumer preferences but also positions your brand as a leader in sustainability and innovation.

Embracing customization and aesthetics in kraft paper packaging can set you apart in today's competitive landscape.

Cost-Effectiveness Factors

Kraft paper stands out as a budget-friendly choice for businesses seeking effective packaging solutions. Its cost-effectiveness stems from several key factors that make it an attractive option.

First, kraft paper production generally incurs lower costs compared to plastic and glass alternatives, giving you an economical edge. The price varies by weight, typically between 25 and 80 lbs, ensuring competitive pricing that suits various packaging needs.

Here are some cost-effectiveness factors to evaluate:

- Utilization of recycled pulp reduces raw material expenses and minimizes environmental impact.

- Strength and durability allow for less material usage, lowering overall material expenditures.

- Recyclability and reusability contribute to long-term cost savings by cutting waste disposal fees.

- Sustainability practices promote a positive brand image, further enhancing customer loyalty.

Frequently Asked Questions

How Do You Identify Kraft Paper?

To identify kraft paper, look for its distinct brown color if it's unbleached, or a white hue if bleached.

You'll notice its coarse texture when you touch it, which sets it apart from smoother papers.

Check the weight; thicker kraft paper typically feels sturdier and is used for heavy-duty tasks.

Finally, consider its eco-friendliness; if it's recyclable and made from sustainably sourced materials, you've likely got kraft paper in hand.

What Are the Qualities of Kraft Paper?

Kraft paper's qualities are impressive and versatile.

You'll notice its exceptional tensile strength, thanks to high cellulose content, making it more durable than regular paper. It typically weighs between 18 and 200 lbs, with common options around 25 to 80 lbs.

You'll appreciate its natural brown color, excellent tear resistance, and moisture resistance.

If you're looking for a clean surface for printing, bleached kraft paper offers that, albeit with slightly less strength.

What Markers Work Best on Kraft Paper?

When working on kraft paper, you'll find that gel pens and permanent markers are your best friends. They provide vibrant colors and bold lines that pop against the brown backdrop.

Colored pencils offer great blending options, while chalk markers allow for temporary designs that you can easily wipe off.

Don't forget about Sharpies—they deliver consistent ink flow and quick drying times, making them perfect for any project on kraft paper.

What Are the Parameters for Kraft Paper Quality?

When evaluating kraft paper quality, you should consider several key parameters.

Start with the weight, typically between 25 to 80 lbs, which directly affects its strength and application.

Next, check the tensile strength, particularly in natural kraft.

Guarantee the moisture content stays between 6-8% for ideal bonding.

Finally, evaluate the thickness and purity of the pulp used, as these factors greatly influence durability and overall performance.

Conclusion

To summarize, understanding the indicators of kraft paper helps you make informed choices for various applications. Its strength and durability, combined with environmental benefits, make it a popular option in food packaging and beyond. As you consider color variations and quality, keep an eye on market trends and consumer preferences that influence your decisions. Ultimately, you'll find that kraft paper is not only cost-effective but also aligns with sustainable practices that benefit both you and the planet.