Water-resistant cardboard isn’t fully waterproof, so don’t assume it can handle prolonged water exposure. It works as a moisture barrier thanks to coatings like wax, polymer, or hydrophobic surfaces, but heavy or continuous water contact can still cause warping or damage. Many believe it’s completely waterproof, which is a misconception. To learn how these coatings function and when to use them effectively, keep exploring the facts behind water resistance and your packaging options.

Key Takeaways

- Water-resistant cardboard acts as a moisture barrier but is not fully waterproof or suitable for prolonged water exposure.

- Proper coatings like wax or polymers enhance water resistance but can be damaged by scratches or sustained moisture.

- Water-resistant cardboard is designed for temporary moisture protection, unlike waterproof materials with multilayer or membrane structures.

- Environmental factors such as humidity, temperature, and surface integrity influence the durability of water-resistant coatings.

- Eco-friendly, water-resistant coatings are available, but they may impact recyclability and biodegradability of the cardboard.

What Is Water-Resistant Cardboard and How Is It Made?

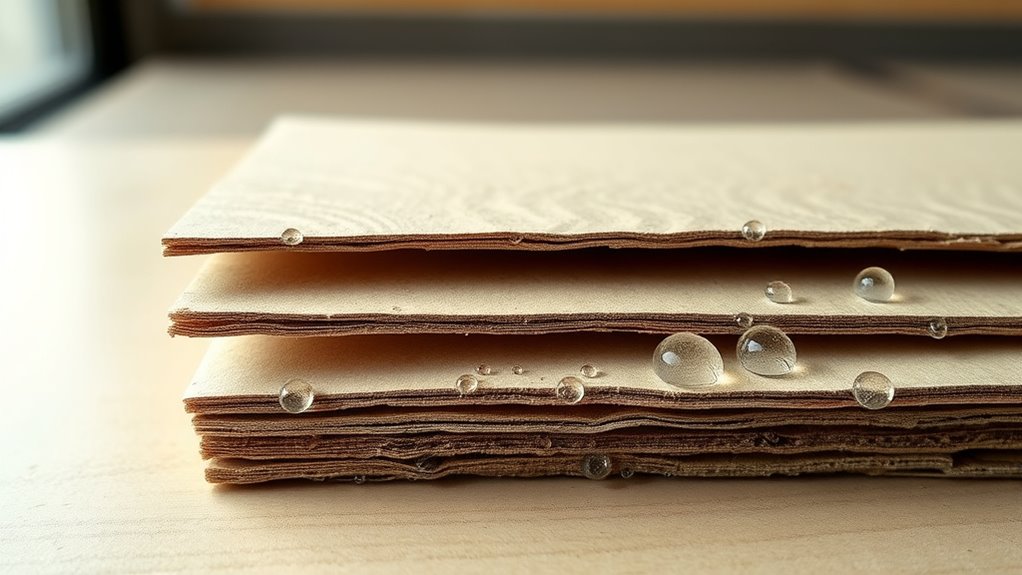

Water-resistant cardboard is specially designed to withstand moisture and prevent water from damaging its structure. You achieve this by applying a water-resistant coating during manufacturing processes, which forms a protective barrier on the surface. These coatings often include wax, polymer, or other hydrophobic materials that repel water and slow its absorption. The manufacturing process involves treating standard cardboard with these coatings either through spraying, dipping, or laminating methods. This treatment ensures the cardboard retains its strength and durability even when exposed to damp conditions. Additionally, modern innovations in water-resistant coatings have improved the environmental footprint of these materials. Advances in eco-friendly materials have led to the development of more sustainable coatings that are less harmful to the environment. Moreover, ongoing research into biodegradable coatings aims to further reduce environmental impact without compromising water resistance. Furthermore, the incorporation of sustainable manufacturing practices has become increasingly important in producing eco-friendly water-resistant cardboard. As a result, water-resistant cardboard provides a practical solution for packaging needs in environments prone to moisture, and ongoing research aims to make these coatings even more eco-friendly.

Common Misconceptions About Water Resistance

Many people believe that water-resistant cardboard is completely waterproof and can withstand heavy exposure to water without any damage. This is a common misconception. In reality, the coating durability varies, and most water-resistant cardboards are designed to serve as moisture barriers rather than fully waterproof materials. They can handle light splashes or brief exposure but won’t hold up under prolonged or intense water contact. Relying on water-resistant cardboard for heavy or continuous water exposure can lead to warping, weakening, or failure. It’s important to understand that water resistance is about minimizing water penetration, not eliminating it. The moisture barrier properties of water-resistant cardboard help protect against incidental water but are not suitable for prolonged submersion or heavy rain. Additionally, understanding the material properties of water-resistant cardboard ensures you select the appropriate material for your specific application. Recognizing these water resistance limitations helps you choose the right material for your needs and prevents disappointment or damage caused by overestimating their capabilities. Even with proper knowledge, it’s essential to consider the intended use to determine if water-resistant cardboard is appropriate for your project.

The Different Types of Water-Resistant Coatings and Treatments

Different types of water-resistant coatings and treatments vary in their composition and effectiveness, allowing you to select the best option for your specific needs. Coating application methods include spray-on, brush-on, or dip treatments, each suited for different situations. There are wax-based coatings, which create a physical barrier, and polymer-based treatments that form a waterproof film. Some treatments use silicone or acrylic compounds for added flexibility and durability. The choice depends on factors like the level of water exposure and the type of cardboard used. Applying these treatments correctly ensures superior water resistance, whether you’re aiming for temporary protection or long-lasting results. Understanding the different treatment methods helps you make informed decisions to enhance your cardboard’s water resistance effectively. Additionally, the effectiveness of water-resistant coatings can be influenced by the safety features of their application, ensuring safe use during the treatment process. For example, selecting treatments with non-toxic components can be particularly important for projects involving food packaging or children’s items. Moreover, considering the environmental impact of the coatings can help reduce your ecological footprint and promote sustainability. Incorporating knowledge about application techniques can also improve the longevity and performance of the coatings you choose. It is also beneficial to consider the adhesion properties of the coating to ensure it bonds well to different types of cardboard and provides reliable protection over time.

How Water-Resistant Cardboard Performs Under Different Conditions

The effectiveness of water-resistant cardboard depends heavily on the conditions it faces. In high humidity or prolonged exposure to moisture, water absorption can increase, weakening the material over time. While treatments help resist water initially, they don’t make the cardboard completely waterproof. Surface damage, such as scratches or punctures, can compromise its protective coating, allowing water to seep in and accelerate deterioration. Cold, wet environments can cause the coatings to crack or peel, reducing effectiveness. Conversely, in dry conditions, water-resistant cardboard performs well, maintaining strength and shape. However, exposure to direct water or heavy rain can quickly undermine its resistance, especially if surface damage occurs. Additionally, headphone compatibility can influence how well certain protective coatings adhere and perform under various conditions. Ensuring proper material protection and understanding environmental factors are key to maximizing durability. Recognizing the limitations of water resistance helps in selecting suitable materials for specific environments. Overall, understanding these variables helps you gauge when water-resistant cardboard will perform reliably, emphasizing the importance of considering environmental factors in performance longevity.

Comparing Water-Resistant Cardboard to Waterproof Materials

Water-resistant cardboard and waterproof materials differ mainly in their composition and how well they resist water. You’ll notice that waterproof options often use synthetic or coated layers, providing higher water resistance. Understanding these differences helps you choose the right material for your needs. Additionally, selecting materials with robust safety measures can ensure better protection against water damage in various applications. For example, some waterproof materials incorporate advanced waterproofing technology to improve durability and water resistance. The choice of material also depends on factors like aesthetic appeal and environmental considerations, which are important in home decor and packaging.

Material Composition Differences

While water-resistant cardboard is treated with coatings or additives to repel moisture, waterproof materials often rely on entirely different compositions to achieve their barrier properties. Water-resistant cardboard typically uses coating formulations made from waxes, resins, or plastics applied to its surface, which block water penetration temporarily. In contrast, waterproof materials may incorporate fiber reinforcement, such as glass fibers or synthetic polymers, embedded within the structure to provide durability and moisture resistance from within. These materials often combine multiple layers, each with specific functions, like a waterproof membrane or a polymer core, making them inherently resistant rather than relying solely on surface coatings. This fundamental difference in composition means waterproof materials tend to offer longer-lasting protection and better performance in demanding environments.

Levels of Water Resistance

Although water-resistant cardboard can withstand light exposure to moisture, its protective layer often wears over time, reducing effectiveness. Water resistant coatings provide a barrier that slows moisture penetration, but they don’t make the material fully waterproof. This means your cardboard offers limited moisture barrier properties compared to true waterproof materials like plastics or sealed metals. Waterproof options use specialized membranes or treatments that prevent water from passing through entirely, regardless of exposure duration. Water-resistant cardboard, by contrast, is designed for short-term or light moisture exposure. When comparing levels of water resistance, consider your needs carefully. For prolonged or heavy moisture exposure, waterproof materials are essential. Water-resistant coatings help, but they’re not a substitute for fully waterproof solutions when durability in wet conditions is critical.

Limitations and Vulnerabilities of Water-Resistant Cardboard

Water-resistant cardboard isn’t foolproof; it can still absorb moisture over time. You might notice its structural strength weakening when exposed to prolonged dampness. Environmental factors like humidity and temperature can accelerate its degradation, making it less reliable in certain conditions.

Limited Moisture Resistance

Have you ever wondered how water-resistant cardboard holds up in real-world conditions? While surface treatment helps, it doesn’t make the material completely waterproof. Moisture penetration can still occur over time, especially with continuous exposure or high humidity. Water-resistant coatings often provide only limited moisture resistance, meaning they can be compromised by:

- Prolonged contact with water or rain

- Scratches or damage to the surface treatment

- Exposure to moisture at seams or edges

These vulnerabilities highlight that water-resistant cardboard isn’t fully waterproof. It’s designed to resist moisture temporarily but isn’t suitable for long-term or heavy exposure situations. Understanding these limitations helps you choose the right packaging or product for your needs.

Structural Integrity Risks

While water-resistant coatings provide some protection, they can still weaken the structural integrity of cardboard under certain conditions. If the coating is compromised or develops cracks, water absorption can occur through these vulnerabilities. As moisture infiltrates, the cardboard’s fibers lose their strength, increasing the risk of structural failure. Over time, repeated exposure to moisture—even with coatings—can cause warping, sagging, or collapsing of the cardboard structure. Water absorption weakens the material, reducing its load-bearing capacity and making it more prone to breakage. You might notice that water-resistant cardboard isn’t as durable as you’d expect when subjected to prolonged or intense moisture exposure. Ultimately, the integrity of the material depends on the quality of the coating and exposure conditions.

Environmental Degradation Factors

Ever wondered why water-resistant cardboard still isn’t invincible? Its environmental vulnerabilities can cause degradation over time. Exposure to harsh elements like prolonged moisture, UV rays, or extreme temperatures weakens its protective coatings. This leads to issues such as:

- Recycling challenges, since water-resistant treatments can complicate processing and reduce recyclability.

- Biodegradability concerns, as some water-resistant coatings hinder natural breakdown, contributing to environmental waste.

- Structural deterioration, as continuous exposure causes the material to lose integrity faster than untreated cardboard.

While water-resistant cardboard extends usability, it isn’t perfect. Its resilience depends on environmental conditions and the type of treatment used. Understanding these limitations helps you better assess its environmental impact and recycling potential.

Best Practices for Using Water-Resistant Cardboard in Packaging

To guarantee water-resistant cardboard performs effectively in packaging, you should follow specific best practices that maximize its durability and functionality. First, verify your packaging design minimizes exposure to water by using appropriate sealing and protective coatings. Keep in mind that recycling challenges may arise with water-resistant materials, so clearly label packages to facilitate proper disposal and recycling efforts. Proper handling also involves avoiding excessive moisture during storage and transit, which can compromise the water-resistant layer. Additionally, leveraging branding opportunities through customized printing on water-resistant surfaces can enhance your product’s appeal without sacrificing protection. By integrating these practices, you not only improve performance but also demonstrate environmental responsibility and create a strong visual identity for your brand.

Environmental Impact and Sustainability of Water-Resistant Options

Water-resistant cardboard offers practical benefits in packaging, but its environmental footprint warrants careful consideration. You should be aware of biodegradability concerns, as many coatings hinder natural decomposition. Recyclability challenges also arise because waterproof treatments often interfere with standard recycling processes, making it harder to reuse materials sustainably. To understand the impact better, consider these points:

- Some water-resistant coatings are not biodegradable, risking environmental persistence.

- Recyclability may be compromised by chemical treatments, reducing circularity.

- Eco-friendly alternatives are emerging but aren’t yet widely adopted, limiting options for sustainable packaging.

Innovations and Future Developments in Water-Resistant Cardboard

Advancements in material science are driving the development of more sustainable and effective water-resistant cardboard. Researchers are exploring biodegradable options that break down naturally, reducing waste and environmental impact. These innovations aim to replace traditional chemical treatments with eco-friendly coatings derived from natural substances like plant-based polymers or mineral-based compounds. Such coatings provide water resistance without compromising recyclability or biodegradability. Future developments focus on creating multi-functional materials that combine durability with sustainability, enabling packaging to withstand moisture while remaining environmentally friendly. You can expect to see more water-resistant cardboards that meet industry standards and consumer demands for greener products. These innovations will help bridge the gap between performance and sustainability, making water-resistant cardboard a smarter choice for eco-conscious packaging solutions.

Tips for Choosing the Right Material for Your Packaging Needs

When selecting packaging materials, consider how durable and protective they need to be for your products. You should also weigh the costs and how eco-friendly the options are to fit your budget and sustainability goals. Making the right choice guarantees your packaging meets both your practical needs and environmental responsibilities.

Durability and Protection

Choosing the right material for your packaging is crucial to guarantee your products stay protected during transit and storage. Durability and protection depend on the strength of the material and its resistance to damage. When selecting water-resistant cardboard, consider how well it withstands moisture without compromising integrity. Keep in mind biodegradability concerns, as some options may not break down easily, affecting environmental impact. Additionally, aesthetic considerations matter, especially if your packaging reflects your brand image. To make an informed choice, evaluate:

- Resistance to tearing and crushing

- Moisture protection capabilities

- Environmental impact and biodegradability

Balancing durability with eco-friendliness ensures your packaging is both robust and responsible, providing the protection your products need without sacrificing environmental values.

Cost and Sustainability

Balancing cost and sustainability is key when selecting water-resistant cardboard for your packaging. A thorough cost analysis helps you determine whether the higher expense of treated cardboard aligns with your budget and product value. Keep sustainability concerns in mind, as eco-friendly options may reduce environmental impact but sometimes come at a premium. Consider materials that offer durability without excessive costs, and look into suppliers committed to sustainable practices. While water-resistant treatments can increase initial costs, they might save money in the long run by reducing damage and waste. Weigh these factors carefully to make an informed decision that meets your budget constraints and aligns with your sustainability goals. Ultimately, choosing the right material involves balancing immediate costs with environmental responsibility.

Frequently Asked Questions

How Long Does Water-Resistant Coating Last Before Degrading?

You’re wondering about the coating durability and how long water-resistant coating lasts before degrading. Typically, it depends on the quality of the coating and usage conditions. Most coatings last around 3 to 6 months with regular exposure to moisture, but heavy wear or harsh environments can accelerate degradation. Keep in mind, proper application and maintenance can extend the degradation timeline, ensuring your cardboard stays water-resistant longer.

Can Water-Resistant Cardboard Be Recycled Easily?

You might wonder if water-resistant cardboard is easy to recycle. While it’s recyclable, biodegradability concerns arise because the water-resistant coating can hinder decomposition. This coating may increase cost implications during recycling processes and affect environmental impact. Handling it properly is essential. You should check local recycling guidelines, as some facilities accept water-resistant cardboard, but others might not due to these challenges.

Is Water-Resistant Cardboard Suitable for Outdoor Applications?

You might wonder if water-resistant cardboard suits outdoor use. It offers good outdoor durability and weather resistance, making it suitable for temporary outdoor displays or packaging. However, it’s not designed for long-term exposure to harsh elements. If you need something that withstands prolonged rain or snow, consider more durable materials. For short-term outdoor applications, water-resistant cardboard can work well, but for extended outdoor durability, explore other weather-resistant options.

Does Coating Affect the Recyclability of Cardboard?

Is coating the hero or villain in cardboard’s story? When you add a coating, it can impact the recyclability, as the environmental impact depends on its composition and coating durability. Think of it as a delicate dance—balancing protection with sustainability. You’ll want to choose coatings that maintain durability but don’t hinder recycling, ensuring your eco-conscious efforts truly make a difference without compromising the environment.

Are There Health Concerns With Chemical Treatments on Water-Resistant Cardboard?

You might wonder if chemical treatments on water-resistant cardboard pose health concerns. Generally, manufacturers aim to minimize chemical exposure, but some treatments could cause allergenic risks if you’re sensitive or allergic. It’s wise to check product labels and choose treated cardboard from reputable sources. While most treatments are safe for everyday use, staying informed helps you reduce potential allergenic risks and avoid unnecessary chemical exposure.

Conclusion

Understanding water-resistant cardboard helps you make smarter packaging choices, saving you from soggy surprises and ruined goods. Remember, not all coatings are created equal—some are more like a knight’s armor, while others are more like a knight’s chainmail. Stay informed about the latest innovations, and you’ll be as prepared as a pioneer heading west. With the right knowledge, you’ll navigate the world of packaging like a seasoned explorer—no need for a time machine!