High-speed corrugated lines are changing the packaging game for you. With production speeds reaching up to 1,200 meters per minute, they boost efficiency and cut costs. You can quickly switch between designs, making it easier to create customized packaging for e-commerce or retail needs. These advanced systems also reduce waste, enhance quality, and support sustainability efforts by using less material. Plus, the market's growing, driven by a shift towards unique packaging experiences. If you're curious about how you can leverage these innovations, there's much more to uncover about their potential impacts and benefits.

Key Takeaways

- High-speed corrugated lines enhance production efficiency, achieving output rates up to 1,200 meters per minute to meet growing e-commerce demands.

- The integration of automation and advanced technologies reduces labor costs, increases speed by 30%, and minimizes waste in packaging processes.

- Customization in packaging is a key market differentiator, strengthening brand loyalty and responding quickly to changing consumer preferences.

- Sustainable packaging solutions, driven by high-speed lines, reduce raw material usage and transportation emissions, aligning with eco-friendly goals.

- The global corrugated packaging market is projected to grow significantly, driven by innovations in high-speed technology and increasing food packaging consumption.

Revolutionizing Packaging Efficiency

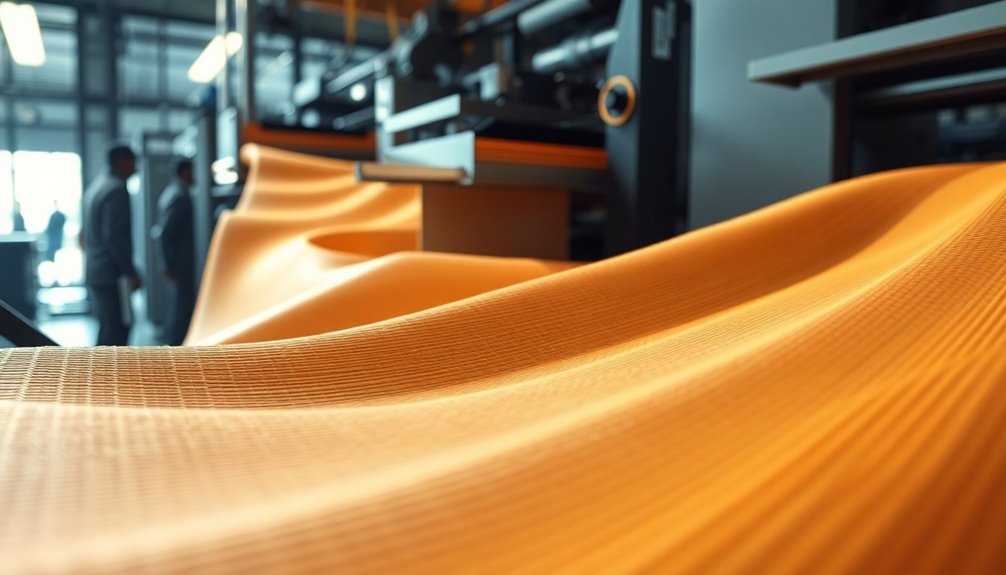

High-speed corrugated lines are transforming the packaging industry by significantly boosting production efficiency. By adopting these lines, you can reduce cycle times and increase output rates, producing up to 1,200 meters of corrugated boxes per minute. Advanced technologies, like high-throughput inkjet presses, facilitate quick changeovers and customization, which are essential for meeting the growing demand for retail-ready packaging.

Moreover, the integration of automation and digitalization enhances precision and minimizes waste, aligning your operations with sustainability goals. This not only meets consumer expectations but also strengthens your brand's commitment to environmental responsibility. With industry consolidation on the rise, investing in high-speed technologies can drive down operating costs while ensuring you stay competitive in the booming e-commerce and retail sectors.

As you embrace these innovations, you'll find that the efficiencies gained from high-speed corrugated lines not only fulfill current demands but also position your business for future growth. By focusing on production efficiency, you'll be better equipped to navigate the evolving landscape of packaging, ensuring your organization remains at the forefront of the industry.

Market Trends in Packaging

There's no denying that market trends in packaging are evolving rapidly, driven by shifts in consumer behavior and technological advancements. The global corrugated packaging market is experiencing significant growth, with a projected increase in value to $205.7 billion by 2025. Despite a recent 7% decline in global corrugated board production, e-commerce's insatiable demand for high-quality solutions continues to push innovations forward.

Retail-ready packaging is gaining traction, particularly in developing markets, as brands look for ways to stand out on crowded shelves. You'll find that the anticipated rise in food packaging consumption is expected to grow from 46% in 2023 to 47% by 2029, emphasizing the critical role of corrugated materials.

Moreover, innovations in digital printing and coating technologies are enhancing the recyclability of various corrugated grades, aligning with the increasing consumer focus on sustainability. As you navigate these trends, keep an eye on high-speed corrugated lines that promise to elevate efficiency and meet the ever-changing demands of the packaging landscape. Embracing these market trends can position you for success in this dynamic industry.

Automate Box Size Optimization

Automating box size optimization is transforming how manufacturers approach packaging efficiency. By utilizing advanced software solutions, you can analyze product dimensions and shipping requirements in real-time, allowing for the creation of custom box sizes. This focus on tailored packaging not only enhances packaging efficiency but also significantly reduces material waste by as much as 15%. As a result, you'll see a noticeable drop in production costs, aligning with the increasing consumer demand for sustainable packaging.

Moreover, implementing automated systems can increase production speed by up to 30%, which is essential for meeting rising e-commerce demands. When packaging is optimized for individual products, you improve supply chain efficiency, ultimately lowering shipping costs and enhancing delivery performance. This streamlined approach ensures that each item is shipped in the right-sized box, minimizing excess space and material use.

Incorporating automating box size optimization into your operations means you're not just cutting costs; you're also contributing to a more sustainable future. With eco-friendly goals in mind, this method positions your company as a leader in the evolving landscape of packaging solutions.

Cost vs. Environmental Impact

When weighing the cost against environmental impact in packaging, it's clear that high-speed corrugated lines offer significant advantages. These lines enhance production efficiency, reducing labor costs and energy consumption, which lowers your overall environmental impact compared to traditional methods. By shifting to high-speed technology, you can use less raw material per unit produced, cutting down on the carbon footprint linked to material sourcing and processing.

Moreover, high-speed corrugated lines enable the creation of lightweight packaging solutions. This not only decreases material usage but also reduces transportation emissions due to lighter loads. While the initial investment in these lines might seem substantial, the long-term savings in operational costs can significantly offset these expenses. Additionally, the potential for increased recyclability of the materials you produce aligns perfectly with sustainability goals in the packaging industry.

Adopting these lines also allows businesses to set clear intentions that guide their transition toward more sustainable practices. Ultimately, adopting high-speed corrugated lines helps you create eco-friendly packaging at a larger scale without sacrificing performance or quality. This shift not only benefits your bottom line but also contributes positively to the environment, making it a win-win for your business and the planet.

Successful Implementations in Retail

High-speed corrugated lines aren't just about reducing costs and environmental impact; they've also revolutionized retail packaging. These lines have played a crucial role in meeting the rising demand for retail-ready packaging (RRP), particularly in budget grocery chains and Asian retail infrastructure. By installing high-throughput inkjet presses, you can enhance the quality and customization of your packaging, making it visually appealing and boosting consumer engagement.

Moreover, successful implementations of high-speed corrugated lines have shown significant reductions in production lead times. This allows you to respond quickly to changing consumer preferences and seasonal demands, keeping your offerings fresh and relevant. In the realm of e-commerce logistics, these lines enable efficient space utilization during transportation, which is vital for cost-effectiveness.

Aligning with the growing trend of sustainability, high-speed corrugated lines often incorporate innovations that improve recyclability and reduce waste in packaging materials. By embracing these advanced solutions, you not only streamline your operations but also contribute positively to the environment, proving that modern retail can be both efficient and responsible.

Emerging Technologies Drive Efficiency

As the demand for quick turnaround times and customization in packaging continues to surge, emerging technologies are reshaping the efficiency of corrugated production lines. High-speed corrugated lines are at the forefront, capable of producing up to 600 linear feet of material per minute. This leap in production efficiency is crucial for meeting the needs created by skyrocketing e-commerce sales.

Investments in automation and robotics enhance these lines further, reducing labor costs and improving handling of smaller production runs. This flexibility allows you to cater to diverse customer demands without sacrificing quality. The integration of digital printing technologies offers high-quality graphics and variable data printing, enabling you to create unique, brand-specific packaging solutions.

As you embrace these advancements, you'll also contribute to sustainable packaging efforts, aligning with consumer preferences for environmentally friendly options. The expected market growth in this sector underscores the importance of adopting these high-speed corrugated lines. By investing in these technologies, you're not just increasing production capacity; you're positioning yourself to thrive in a competitive landscape driven by customization and efficiency.

Frequently Asked Questions

What Is the Future of Corrugated Packaging?

The future of corrugated packaging looks promising for you. With market values set to rise and increasing demand, especially in food packaging, you're bound to see growth. Regulatory changes favoring sustainable options will open new doors. As technology advances, you'll benefit from improved efficiency and quality, particularly in e-commerce. The anticipated annual growth rate suggests ongoing opportunities, making now an exciting time to explore innovations in corrugated packaging solutions.

What Is the Future of Corrugated Board Packaging to 2029?

The future of corrugated board packaging looks promising through 2029. You'll see a significant rise in demand, especially in food packaging, which will account for nearly half of total consumption. With the e-commerce boom, innovative and quality packaging solutions will be crucial to enhance consumer experience. Plus, as regulations push for sustainable options, you'll find more brands shifting to corrugated packaging, creating exciting opportunities in the market.

What Is the Market Trend in Corrugated Packaging?

You'll notice that the corrugated packaging market is on a recovery path, projected to grow from $224.4 billion in 2023 to $231.7 billion in 2024. Food packaging drives this demand, accounting for over 46% of usage. As regulations tighten against single-use plastics, opportunities for corrugated solutions will expand. With an average annual growth rate of 2.5% expected until 2029, it's clear the market is steadily evolving.

Who Is the Largest Company of Corrugated Packaging?

If you're curious about the largest company in corrugated packaging, it's International Paper. In 2022, they generated over $21 billion in revenue, making them a top supplier of containerboard and corrugated solutions. This dominance allows them to leverage economies of scale and advanced technologies. Other significant players include Smurfit Kappa, WestRock, and DS Smith, but International Paper leads the pack, shaping the industry with its vast resources and innovative approaches.