China's corrugated roll providers offer unbeatable prices, often between $2,800 and $2,910 per ton. Their advanced manufacturing technology boosts efficiency and reduces waste, while lower labor costs keep expenses down. By incorporating recycled materials, they align with eco-friendly standards, which attracts more customers. Bulk purchasing further enhances cost savings, as minimum orders start at just 10 tons. Plus, stable demand from e-commerce ensures consistent pricing. Overall, their commitment to quality and innovation sets them apart. Stay with us to uncover more about how these factors contribute to their market edge.

Key Takeaways

- Strong production capacity and advanced technology enable lower operational costs for Chinese corrugated roll providers.

- Bulk purchasing options allow significant savings, with prices averaging $2,800 to $2,900 per ton.

- Integration of recycled materials meets eco-friendly standards while reducing costs, appealing to sustainability-focused buyers.

- Efficient supply chain logistics and government support contribute to competitive pricing in the packaging industry.

- Growing demand for e-commerce packaging stabilizes prices, making Chinese providers a reliable choice for businesses.

Unmatched Pricing in Corrugated Rolls

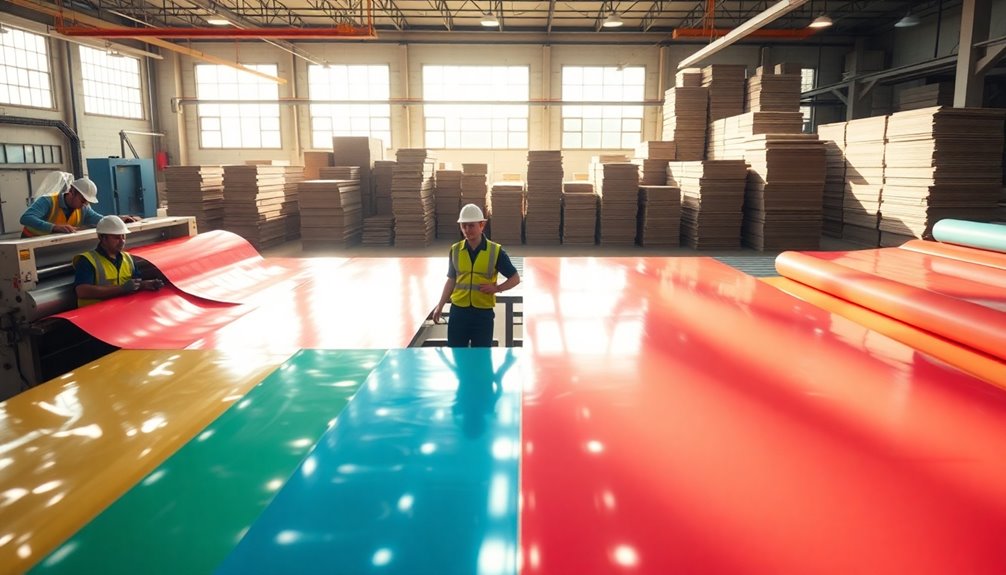

When it comes to corrugated rolls, few can match the competitive pricing offered by Chinese suppliers. With an average export price of around $2,910 per tonne, China stands out in the global market. Their robust production capacity allows them to achieve lower costs, especially when it comes to bulk orders, often starting at just 10 tons. This flexibility makes it easier for smaller businesses to access high-quality packaging solutions without breaking the bank.

Chinese manufacturers excel in integrating advanced technology into their production processes, enhancing efficiency while minimizing waste. This commitment to quality control ensures that you receive a reliable product at an attractive price. Moreover, China's significant investment in sustainable practices and recycled materials not only addresses eco-friendliness but also contributes to cost savings for you.

Market Dynamics of Corrugated Rolls

The market dynamics of corrugated rolls are shaped by several key factors that influence pricing and demand. China's ability to maintain competitive prices stems from its efficient production processes and lower labor costs, resulting in prices around $2,800 to $2,900 per ton. As China leads global exports of corrugated boxes, the average export price of $2,910 per ton reflects strong production capabilities and favorable demand-supply dynamics.

The growing demand for e-commerce packaging solutions further enhances the market's competitiveness. As online shopping continues to rise, the need for affordable and reliable packaging options increases. This trend stabilizes prices, making it easier for you to find cost-effective solutions for your packaging needs.

Additionally, environmental sustainability trends play a crucial role in the industry. By incorporating recycled materials into production, Chinese manufacturers not only adhere to global eco-friendly standards but also manage to keep prices competitive. As the market for corrugated products is expected to grow through 2024, these factors will continue to drive innovation and affordability in the corrugated roll sector, ensuring you have access to quality products at unbeatable prices.

Bulk Purchasing for Cost Savings

Bulk purchasing corrugated rolls from Chinese providers offers significant cost savings for businesses looking to optimize their packaging expenses. When you buy in larger quantities, you typically gain access to lower prices, with average costs hovering around $2800-2900 per ton. This reduction in per-unit expenses means your bottom line benefits directly.

Many Chinese suppliers implement competitive pricing structures that reward you for ordering more. For instance, as your order quantity increases, the price per ton decreases, encouraging you to stock up and maximize your savings. With minimum order quantities (MOQs) often starting at just 10 tons, you can easily meet these requirements while enjoying substantial bulk purchasing advantages.

Additionally, leveraging the high production capacity and efficiency of Chinese manufacturers ensures a steady supply of corrugated rolls, which is crucial for your packaging needs. As e-commerce continues to drive the global demand for corrugated boxes, price stability among suppliers makes bulk purchasing an even more attractive option. By taking advantage of these opportunities, you can secure significant cost savings and enhance your operational efficiency in the long run. Furthermore, understanding operating hours of suppliers can further enhance your purchasing strategy and optimize your procurement process.

Price Fluctuations Impact Supply Chains

Price fluctuations in the corrugated roll market can directly impact your supply chain efficiency and costs. As demand for corrugated paper boxes rises, the average export price can reach as high as $1,882 per tonne, reflecting the dynamics that influence your pricing strategies. Global supply chain disruptions have led to increased price volatility, affecting the cost of raw materials and transportation. This volatility makes it crucial for you to stay aware of how price fluctuations can alter your expenses.

With China's leadership in corrugated box exports, priced at an average of $2,910 per tonne, their competitive edge can significantly affect your supply chain economics, particularly if you're one of the major importers like those from the Netherlands or Mexico, which together account for over 33% of global imports. As global trade for corrugated products is expected to grow through 2024, fluctuations in demand could result in further price adjustments. Ultimately, understanding these factors will help you navigate the complexities of your supply chain and make informed purchasing decisions. Keep an eye on these trends to maintain cost efficiency in your operations.

Successful Cost Reduction Strategies

Navigating the challenges posed by price fluctuations requires implementing effective cost reduction strategies. To stay competitive in the global market, you need to leverage advanced manufacturing technology. This technology minimizes waste and enhances production processes, which significantly lowers operational costs. By doing so, you can offer corrugated rolls at prices around $2800-2900 per ton, making your products more attractive to buyers.

Access to affordable raw materials, like recycled paper, also plays a crucial role in your cost reduction efforts. By utilizing these materials, you not only maintain cost-effective pricing but can also commit to sustainability practices—a growing concern among consumers.

Moreover, focusing on supply chain efficiencies can greatly improve your overall affordability. Streamlining logistics ensures quick turnaround times and minimizes shipping costs, allowing you to pass those savings onto your customers.

Finally, take advantage of government support for the packaging industry, which often includes subsidies and infrastructure investments. These initiatives can help you further reduce production costs and enhance your competitive edge. By implementing these strategies, you can effectively navigate price fluctuations while delivering exceptional value.

Price Advantages Drive Demand

China's competitively priced corrugated rolls, ranging from $2,800 to $2,900 per ton, create a strong demand in the global market. These price advantages make Chinese products highly attractive compared to alternatives from other countries, which often have higher costs. As a buyer, you'll find that the efficient supply chain and large-scale production capabilities in China enable these competitive prices.

Furthermore, the use of recycled materials in manufacturing aligns with sustainability trends, helping to reduce raw material sourcing costs. This commitment to eco-friendly practices not only lowers expenses but also appeals to companies looking for responsible packaging solutions.

With the rapid growth of e-commerce, the demand for affordable packaging solutions continues to rise. Chinese manufacturers are well-positioned to meet this need, driving further price advantages in the corrugated roll market. The combination of low production costs and high-quality products ensures that buyers like you can rely on China's corrugated rolls for your packaging needs, ultimately enhancing your profitability. As competition intensifies, you can expect these price advantages to persist, solidifying China's status as a leader in the global corrugated roll market.

Frequently Asked Questions

Is Corrugated Cardboard More Expensive?

Yes, corrugated cardboard can be more expensive than other packaging options. This price increase is mainly due to rising raw material costs and supply chain disruptions. However, you'll find that its durability and versatility often justify the higher cost. When you consider the protection it offers your products and potential savings on shipping, you might realize it's still a cost-effective choice for your packaging needs.

Why Is Corrugated Paper Stronger?

Corrugated paper's strength comes from its unique fluted structure, which you can see when you look closely. This design sandwiches a wavy layer between two flat liners, giving it exceptional resistance against bending and crushing. Its layering not only makes it durable but also lightweight, helping you save on shipping costs. Plus, its ability to withstand moisture and temperature changes means your packages stay protected, no matter the conditions. That's why it's so strong!

In Which Country Was Corrugated Box First Used for Packaging?

You'll find that the first use of corrugated boxes for packaging dates back to 1871 in the United Kingdom. Initially, these boxes were developed as liners for hats. By 1895, the U.S. produced the first complete corrugated box, transforming packaging methods. This innovation led to widespread adoption across various industries, especially in shipping, due to the lightweight and durable nature of corrugated materials, which remain dominant in the packaging market today.

Why Is Corrugated Board Good?

Corrugated board's durability makes it perfect for protecting fragile items during shipping and storage. Its lightweight nature helps you save on shipping costs, enhancing your logistics efficiency. You can easily customize corrugated board for size, shape, and branding, boosting your brand's visibility. Plus, since it's primarily made from recycled materials, it aligns with eco-friendly practices, appealing to today's environmentally conscious consumers. Overall, it's a versatile and sustainable packaging solution for your business needs.