3D printing and new materials are transforming sculpture by offering you unprecedented creative freedom, precision, and innovation. Advanced ceramics, flexible elastomers, and recycled composites let you explore diverse textures and complex designs that traditional methods struggle to achieve. Emerging printing techniques like multi-material and large-format production boost efficiency and reduce costs. If you want to discover how these breakthroughs open new artistic horizons, explore further to see what’s shaping sculpture’s exciting future.

Key Takeaways

- Advanced materials like bio-resins, flexible elastomers, and metal alloys enable diverse textures and enhanced durability in sculptural 3D printing.

- Multi-material printing allows for hybrid textures and complex surface finishes, expanding artistic expression.

- Innovations in composites and biodegradable materials promote sustainability and eco-conscious artistic practices.

- High-resolution and large-format 3D printing facilitate intricate, large-scale sculptures with faster production times.

- Hybrid manufacturing and AI-driven workflows improve precision, efficiency, and enable complex, innovative sculptural designs.

The Expanding Horizons of 3D Printing in Sculpture

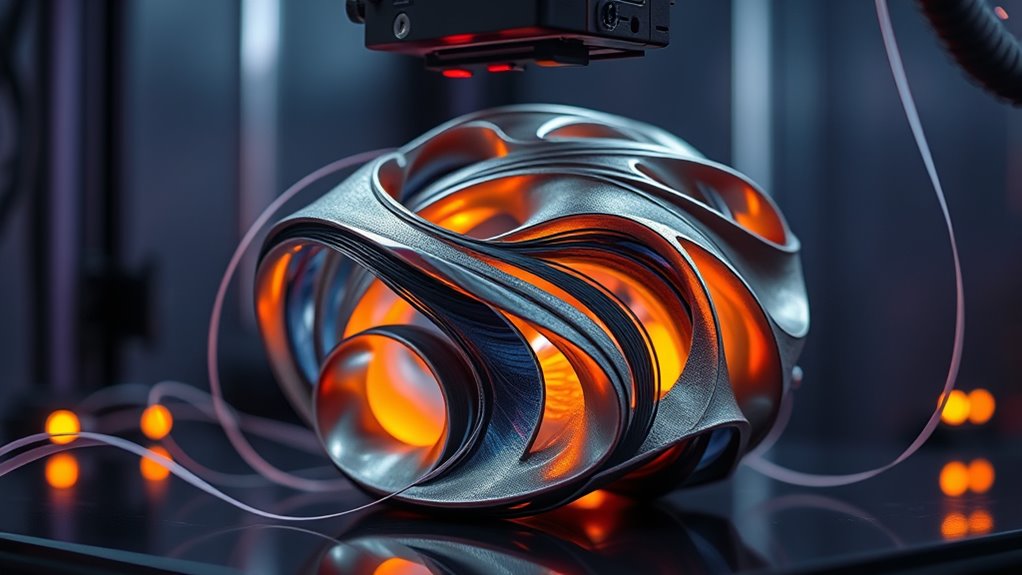

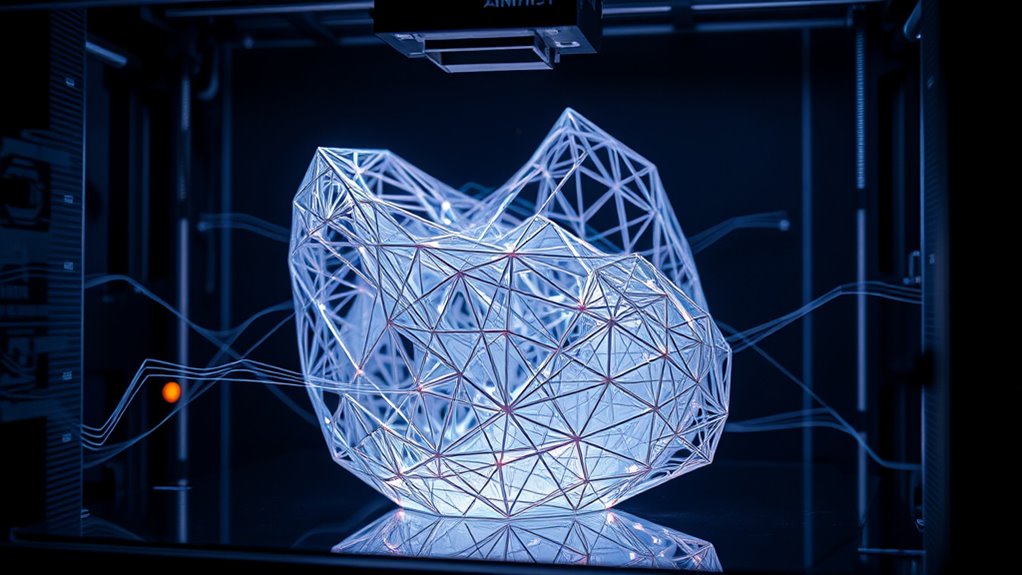

3D printing is transforming sculpture by offering you unprecedented creative freedom and the ability to design complex, intricate forms that traditional methods can’t easily achieve. You can experiment with detailed geometries and delicate patterns, pushing artistic boundaries. This technology allows you to combine painting and 3D forms, broadening visual perspectives and storytelling options. The shaping capabilities are nearly limitless, enabling the creation of large-scale, multi-component assemblies with durable, lightweight materials. You can produce hollow or lattice structures, optimizing strength and material use. Digital workflows streamline your process, reducing time and manual effort while increasing precision. As a result, you can rapidly iterate ideas from concept to finished piece, expanding your artistic possibilities and exploring new sculptural territories that were previously out of reach. Moreover, advances in new materials are further expanding the potential for innovative textures and finishes in sculpture, including the development of advanced composite materials that offer enhanced durability and aesthetic qualities.] Additionally, understanding design optimization techniques can help maximize the structural integrity and aesthetic appeal of your creations.

Breakthrough Materials Transform Artistic Possibilities

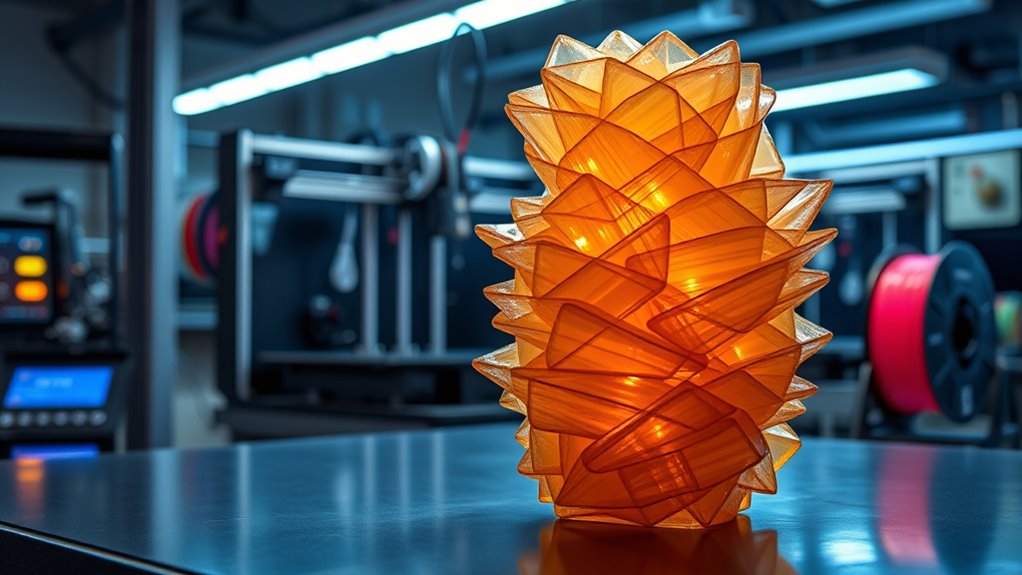

The expanding library of advanced materials is revolutionizing artistic expression through 3D printing. You now have access to a wide range of new options, including advanced ceramics, flexible elastomers, conductive plastics, and bio-based resins, which broaden your creative toolkit. These materials allow for diverse textures and finishes—smooth, matte, glossy, or metallic—enhancing both visual and tactile qualities of your sculptures. They’re engineered for durability, UV resistance, water resistance, and strength, making your works suitable for indoor or outdoor displays. Plus, you can blend or layer materials within a single print, creating hybrid textures impossible with traditional methods. Sustainable options like biodegradable and recycled materials support eco-conscious art. The development of new materials such as bio-based resins and recycled plastics reflects the industry’s focus on sustainability. As material properties continue to evolve, artists can craft lightweight, complex, and adaptive sculptures that push artistic boundaries, enabled by advanced material science and innovative manufacturing techniques.

Innovations in Printing Technologies and Techniques

Innovations in 3D printing techniques are transforming how sculptures are created, making the process more efficient and precise. Support-free printing and hybrid methods reduce post-processing and enable complex textures and embedded features. These advancements expand artistic possibilities by blending additive manufacturing with traditional craftsmanship, opening new avenues for creativity. Ongoing technological improvements continue to enhance resolution, detail, and material capabilities, further pushing the boundaries of artistic expression. Additionally, water-based materials are gaining popularity for their eco-friendly properties and suitability for intricate designs, with material versatility playing a key role in the evolution of sculptural art. The integration of glycolic acid in various formulations demonstrates how chemical innovations are influencing material development, adding new potential for surface finishing and textures. Furthermore, understanding the Gold IRA options available can help artists and collectors diversify their investments while exploring innovative materials and techniques. Emerging vetted techniques are also helping artists explore innovative forms and finishes.

Advanced Printing Methods

Have you noticed how advancements in printing technologies are transforming the landscape of digital fabrication? Large-format 3D printing is becoming mainstream by 2025, thanks to faster speeds and lower costs. Multi-nozzle and continuous printing cut build times, making large sculptures quicker to produce. Real-time monitoring and adaptive controls guarantee consistent quality and less waste. Faster curing methods, like advanced UV and laser techniques, shorten post-processing. Automation in feedstock handling and part removal increases throughput. Multimaterial and composite printing now let you deposit multiple materials simultaneously, creating complex textures and properties. High-resolution methods like SLA and DLP achieve ultra-fine detail, while micro- and nano-scale techniques open up new possibilities. AI-driven software and cloud workflows streamline design, monitoring, and correction, pushing digital fabrication into a new era. The integration of hybrid manufacturing techniques further enhances the capabilities of large-scale 3D printing, enabling the production of complex, high-precision sculptures with a combination of additive and subtractive processes. Additionally, innovations in natural materials are expanding the scope of sustainable and eco-friendly sculptural projects.] Furthermore, advancements in material technologies are improving the performance ratings based on suction power and durability, which are also driving innovations in material technologies used in printing. A deeper understanding of local store hours helps optimize the timing of large-scale production runs and supply chain logistics.

Hybrid Manufacturing Techniques

Building on recent advances in 3D printing, hybrid manufacturing techniques combine additive and subtractive processes to create more complex and precise parts within a single system. You can build near-net shapes using 3D printing, then refine details with CNC machining for high accuracy and smooth finishes. This approach is ideal for prototyping, complex geometries, and low-volume production. The technology involves components like laser metal deposition and CNC tools controlled by standard G-code, supporting various materials such as metals and foils. Hybrid systems enable tailored applications like mold repair, hardfacing, and intricate design creation. While integration challenges and equipment costs exist, the advantages—faster production, reduced waste, multi-material capabilities, and enhanced precision—make hybrid manufacturing a key innovation shaping the future of sculpture, aerospace, automotive, and healthcare industries. Additionally, the integration of wall organization systems can optimize workspace efficiency and aesthetic appeal in fabrication environments. Incorporating precision control systems further enhances the accuracy and repeatability of hybrid manufacturing processes, which are essential for ensuring consistent quality in complex fabrication tasks. Understanding manufacturing standards is essential to ensure quality and safety in hybrid production environments.

Enhancing Production Efficiency and Cost-Effectiveness

3D printing substantially enhances production efficiency and cost-effectiveness by enabling faster turnaround times and reducing expenses across the manufacturing process. You can develop sculpture molds rapidly, drastically cutting traditional lead times, and make multiple design revisions in hours, accelerating creative and technical adjustments. The direct digital workflow minimizes delays caused by manual modeling and tooling, streamlining your entire process. Cost savings are significant; 82% of manufacturers report notable reductions, thanks to precise material use, lower labor needs, and eliminated tooling costs. Waste is minimized through optimized material use and recycling, supporting sustainable practices. Material optimization contributes further to reducing waste and improving overall efficiency. Consistent output, high precision, and reduced defects ensure quality and batch uniformity. Plus, flexible batch sizes and material options allow you to scale production efficiently, making 3D printing a powerful tool for cost-effective sculpture creation. Additionally, understanding the genetic variation in dog breeds can inspire innovative approaches to material development and coloration in sculpture design. Staying informed about industry standards and advancements in materials can further enhance your creative process and output quality.

Creative Freedom and New Artistic Expression

The rise of 3D printing in sculpture releases unprecedented creative freedom, allowing you to push beyond traditional boundaries. You can craft complex, intricate designs that were once impossible with conventional methods, opening new horizons for artistic expression. Material diversification lets you experiment with textures and finishes, enhancing your sculptures’ aesthetic appeal. The precision of 3D printing captures even the finest details, making your work more refined. You can also build structural complexities and geometries that challenge conventional techniques. Rapid prototyping enables you to test ideas quickly, refining concepts on the fly. This technology inspires unconventional art forms, blends sculpture with architecture or engineering, and fosters collaborations across disciplines. Ultimately, 3D printing empowers you to explore bold, innovative, and interactive artistic visions like never before.

Future Trends Driving the Sculptural Industry

As new materials and technologies continue to advance, the sculptural industry is poised for transformative changes. You’ll see increased use of advanced composites like carbon-fiber and high-performance polymers, offering both strength and flexibility. Metal alloys are becoming more common for their durability, while biodegradable materials push sustainability forward. Multi-material printing enables complex sculptures with varied textures and properties, expanding creative possibilities. Additionally, recycled materials are gaining traction, making eco-friendly practices more accessible. These trends drive innovation across sectors—whether in aerospace, automotive, or entertainment—while supporting greener manufacturing. Expect faster production cycles, more durable and sustainable sculptures, and new artistic expression made possible through technological integration. The future of sculpture hinges on blending cutting-edge materials with innovative processes to redefine what’s artistically achievable.

Embracing Integration: Art, Technology, and Cultural Heritage

How are art, technology, and cultural heritage intertwining to create new opportunities for preservation and expression? You’re witnessing a revolution where 3D printing and digital tools preserve history while expanding artistic horizons. Precise replication restores damaged works without compromising authenticity, and digital reconstruction brings lost art back to life. High-quality replicas allow fragile artifacts to be safely displayed, making cultural treasures accessible worldwide.

| Preservation | Innovation |

|---|---|

| Restoring integrity | Using new materials in sculpture |

| Digital reconstructions | Collaborations between artists and technologists |

| Cultural site revival | Creating educational replicas |

| Global access | Reviving lost art pieces |

Frequently Asked Questions

How Does 3D Printing Influence Traditional Sculpture Craftsmanship?

You might wonder how new technologies impact traditional craftsmanship. 3D printing influences it by offering faster production, greater precision, and complex designs that were hard to achieve manually. It can complement your skills, allowing you to experiment with materials and intricate details. While it may replace some methods, it also enhances your creative possibilities, encouraging a collaborative approach that evolves your craft without losing its core aesthetic values.

What Sustainable Materials Are Emerging in 3D Printed Art?

When it comes to emerging sustainable materials in 3D printed art, you’re riding the wave of eco-conscious innovation. You’ll find options like biodegradable PLA, recycled plastics, coffee ground-based bio-composites, and aluminum alloys from recycled feedstock. These materials help reduce waste and carbon footprints, allowing you to create environmentally friendly artworks. As technology advances, you’ll see more bioplastics, bio-based composites, and localized production methods, making sustainable art more accessible and impactful.

Can 3D Printing Replicate Historical Sculptures Accurately?

You can see that 3D printing can replicate historical sculptures quite accurately. By combining precise 3D scanning with high-resolution printers, you capture fine details, textures, and intricate geometries. Materials like resins, metals, and composites mimic the original finishes, while post-processing techniques add authenticity. This technology minimizes handling risks, allows for educational and display purposes, and preserves cultural heritage, though some weathered patinas and large-scale details still pose challenges.

How Accessible Is 3D Printing Technology for Independent Artists?

You might wonder how accessible 3D printing really is for independent artists. The good news is, it’s becoming more affordable and user-friendly. With online resources, community support, and open design platforms, you can learn and create without extensive training. Entry-level printers and free software help keep costs manageable. While initial investments are necessary, the growing availability of shared knowledge and equipment makes 3D printing increasingly accessible for independent artists like you.

What Ethical Considerations Arise With Digital Sculpture Replication?

Did you know that over 60% of artists worry about their work being copied without permission? When you digitally replicate sculptures, ethical issues come up, like respecting cultural heritage and ensuring authenticity. You need to take into account copyright, avoid misrepresentation, and be transparent about digital alterations. It’s essential to collaborate with communities, protect original creators’ rights, and use technology responsibly to prevent exploitation and preserve artistic integrity.

Conclusion

As you explore the future of sculpture, remember that “the sky’s the limit.” 3D printing and innovative materials open endless creative possibilities, allowing you to push boundaries and embrace new artistic expressions. By integrating technology with tradition, you can shape a vibrant, evolving landscape in sculpture that’s both innovative and meaningful. Stay curious and adaptable—your next masterpiece may be just a print away.