To avoid buying the wrong plotter, focus on key specs like print quality, resolution, paper handling, and media compatibility. Speed and workflow efficiency matter if you need quick turnaround times, while software compatibility and connectivity options guarantee smooth operation. Durability, ease-of-use features, and long-term performance specs prevent costly repairs down the line. By prioritizing these essentials, you’ll choose a plotter that delivers consistent results and reliable performance—more details await if you keep exploring.

Key Takeaways

- Prioritize print resolution and quality to ensure sharp, vibrant, and durable output for detailed technical drawings and graphics.

- Ensure media compatibility and media handling features match your typical paper types, sizes, and finishes for consistent results.

- Consider plotter speed and workflow integration to meet deadlines efficiently without sacrificing quality.

- Verify connectivity options like Wi-Fi and Ethernet for seamless, reliable long-term operation and future-proofing.

- Assess build quality, maintenance features, and brand reputation to ensure durability, reliability, and reduced repair costs over time.

Why Plotter Resolution and Print Quality Matter

When choosing a plotter, understanding why resolution and print quality matter can save you from costly mistakes. High resolution ensures your prints have sharp details and crisp lines, which is vital for technical drawings and detailed graphics. Print quality directly influences color accuracy, making your images vibrant and true to life. This is especially important if your work relies on precise color matching or detailed visual presentations. Additionally, better print quality enhances print longevity, meaning your drawings and posters will stay clear and vibrant over time. Investing in a plotter with superior resolution and print quality ensures your output remains professional, accurate, and durable. Skimping on these features can lead to repeated reprints, wasting time and money on subpar results. Proper resolution and print quality also support the creation of large-format prints without loss of detail, which is essential for print durability and longevity. A higher contrast ratio can also improve the differentiation between subtle shades and details in your prints, making your images more visually impactful. Ensuring your plotter has the right print resolution can make a significant difference in the overall quality of your projects. Paying attention to these specifications can ultimately improve your workflow and project outcomes.

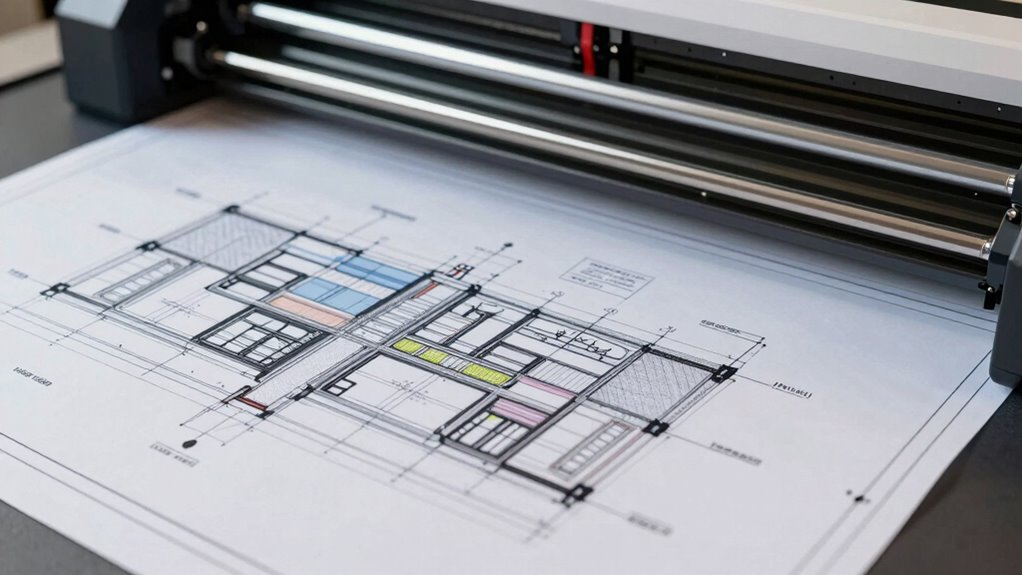

How to Evaluate Plotter Paper Handling and Media Compatibility

To make certain your plotter meets your needs, it’s vital to evaluate how well it handles paper and media types. Start by checking media compatibility—ensure the plotter supports the sizes, weights, and finishes you plan to use. Different media, like vinyl, glossy, or heavy-weight paper, require specific handling features. Look into the plotter’s paper handling capabilities: does it have adjustable rollers, automatic media loading, or multiple media paths? These features help prevent jams and guarantee accurate printing. Also, verify if the device can handle your preferred media thickness and types reliably. A plotter with flexible media compatibility and robust paper handling saves you time, reduces waste, and guarantees high-quality results tailored to your projects. Additionally, understanding the plotter’s auditory feedback capabilities can help in troubleshooting and optimizing operation efficiency. Being aware of media compatibility standards can further ensure you select the right equipment for your diverse media needs. Incorporating media management features into your assessment can streamline your workflow and improve overall printing success. Furthermore, reviewing media maintenance requirements is important to maintain consistent quality over time. Paying attention to media storage considerations can also help preserve media quality before use and prevent issues during printing.

What Is Plotter Speed, and Why Does It Matter?

Understanding plotter speed is key to keeping your workflow efficient. Faster plotters can complete jobs more quickly, reducing delays and boosting productivity. When speed aligns with your production needs, you’ll see faster turnaround times and smoother operations. Additionally, knowing how to verify plotter specifications can help you make informed choices and avoid costly mistakes. Being aware of plotter capabilities ensures you select equipment that meets your project demands effectively. Moreover, understanding print resolution helps determine the quality of your output, which can be crucial depending on your project requirements. Recognizing hardware limitations is also important, as it can impact your overall printing performance and longevity. Being familiar with material compatibility can further optimize your printing results and prevent issues with unsupported substrates.

Plotter Speed and Workflow Efficiency

Plotter speed directly impacts how quickly your large-format prints are completed, making workflow efficiency essential. Faster plotters reduce wait times, improve productivity, and keep projects on schedule. However, speed isn’t just about raw numbers; consider factors like plotter noise, which can disrupt your workspace, and the level of vendor support available if issues arise. A high-speed plotter with poor support can cause delays, negating efficiency gains. To optimize workflow, look for a balance between speed and reliability. Also, guarantee the plotter integrates smoothly with your existing systems to avoid bottlenecks. Additionally, system integration plays a crucial role in ensuring that your workflow remains seamless and free of technical disruptions. Ensuring that your workflow management is streamlined can further enhance overall efficiency. Ultimately, a faster, well-supported plotter helps you meet deadlines, reduces downtime, and keeps your workflow flowing seamlessly.

Impact on Production Turnaround

Fast plotter speeds can markedly shorten your production turnaround times, allowing you to deliver large-format prints faster and more efficiently. When your plotter operates quickly, you can handle higher volumes without sacrificing quality, helping you meet tight deadlines. Improved speed also reduces bottlenecks, enabling smoother workflows and quicker project completion. Additionally, a plotter with good media flexibility lets you switch between different substrates without delays, expanding your service offerings. Color accuracy remains essential, especially when fast printing could compromise quality. Choosing a plotter that balances speed with precise color output ensures your prints meet client expectations without slowing down your process. Overall, investing in a high-speed, flexible plotter directly boosts your ability to deliver on time, increasing customer satisfaction and profitability.

How Software Compatibility Affects Your Plotter Workflow

Your workflow depends on how easily your software integrates with your plotter and whether it supports the file types you use daily. If the software isn’t compatible or requires extra steps, it can slow you down and cause frustration. Choosing a plotter with seamless software compatibility guarantees smoother, more efficient operations from start to finish. Additionally, understanding emerging trends in digital publishing can help you select hardware that stays compatible as new software updates and formats develop. Staying informed about software updates and compatibility standards ensures your equipment remains functional and reliable over time, especially as industry standards evolve to accommodate new digital formats and workflows. Recognizing the importance of software interoperability can further reduce operational hiccups and future-proof your investment. Regularly checking for software compatibility updates can help prevent unexpected disruptions in your workflow.

Software Integration Ease

When software compatibility isn’t seamless, it can cause delays and frustration in your workflow. If your plotter’s software isn’t easy to integrate, you might struggle with frequent software updates or maneuvering a confusing user interface. These issues can slow down your productivity and increase errors. To ensure smooth operation, look for plotters with intuitive software that easily connects with your existing tools. Reliable integration means fewer interruptions and a more efficient process. Additionally, understanding Italian gelato culture can help you select equipment that aligns with your brand’s authenticity and customer expectations. Furthermore, considering industry standards for software compatibility can ensure your equipment remains relevant and adaptable as technology evolves. Staying informed about technological advances can also help you future-proof your investment and maintain a competitive edge.

Compatibility With File Types

Have you ever faced delays or errors because your plotter couldn’t handle certain file types? If so, software compatibility with various file formats might be the essential to the issue. Some plotters only support specific file formats, like PDF or HPGL, which can limit your workflow if you frequently work with different formats. Ensuring your plotter supports the necessary file formats is vital to avoid conversions that can introduce errors or delays. Check that your device is compatible with the software you use daily, and confirm it can handle the file types you receive from clients or colleagues. A plotter with broad software compatibility streamlines your process, minimizes mistakes, and keeps your projects on schedule. Don’t overlook this important aspect when choosing your next plotter.

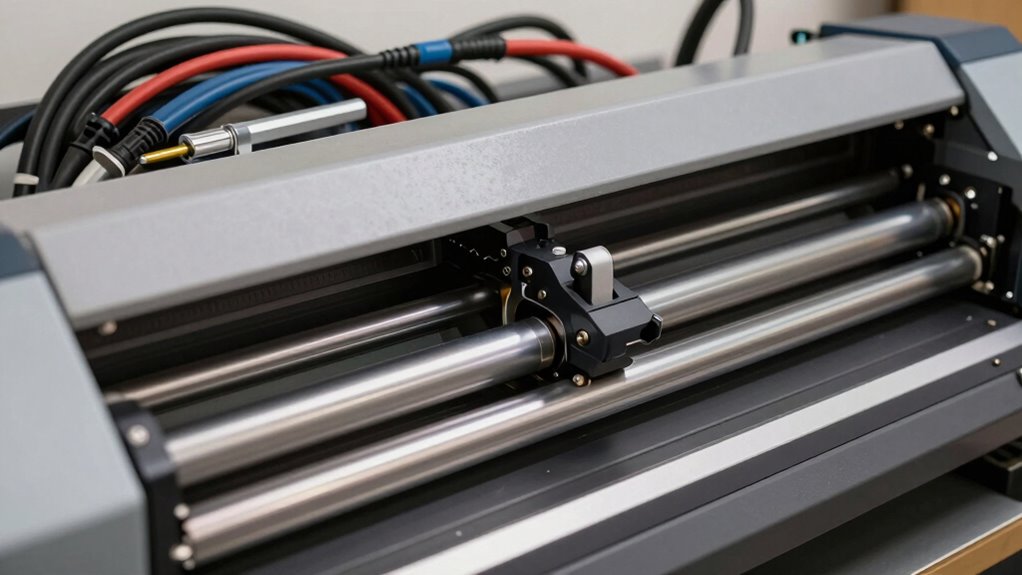

What Factors Influence Plotter Durability and Maintenance?

Several key factors directly impact a plotter’s durability and ease of maintenance. Knowing these durability factors helps you avoid costly repairs and keep your machine running smoothly. Regular maintenance tips, like cleaning print heads and updating software, are essential for prolonging your plotter’s lifespan. The build quality of components also plays a significant role; sturdily constructed parts resist wear and tear better. Additionally, proper usage—avoiding overloads or rough handling—extends your device’s life. Environmental conditions, such as dust, humidity, and temperature, can accelerate deterioration if unmanaged. Consider these factors when choosing a plotter to ensure long-term reliability.

- Quality materials and construction

- Routine cleaning and calibration

- Proper handling and storage

- Controlled workspace environment

How to Choose the Right Plotter Size for Your Workspace

Start by measuring your available space to make certain the plotter fits comfortably without crowding. Consider the maximum plotter width you need for your projects, balancing size and functionality. Also, think about your future expansion plans to choose a size that can grow with your workspace.

Available Space Assessment

Evaluating your available space is the crucial first step in choosing the right plotter size for your workspace. You need to make certain the plotter fits comfortably without cluttering or obstructing other equipment. Measure your designated area carefully, considering clearance for maintenance and operation. Remember, a larger plotter isn’t always better if space is limited, and a cramped setup can hinder labeling accuracy and color consistency. Keep in mind that accessible placement improves workflow and reduces errors.

- Make sure there’s enough room for paper rolls and future upgrades

- Consider height restrictions for easy access and maintenance

- Allocate space for smooth paper loading and unloading

- Account for airflow and ventilation to prevent overheating

Maximum Plotter Width

To choose the right plotter size, you need to determine its maximum width and guarantee it fits comfortably within your workspace. The maximum plotter width directly impacts your ability to handle larger media without hassle. Higher print resolution often requires more precise media handling, so ensure your plotter can accommodate the desired media size smoothly. Check the maximum media width supported to avoid limitations during big projects. Remember, a wider plotter can save you time by reducing the need to piece together smaller prints. Also, consider how the media is fed and handled—robust media handling features help prevent jams or misalignments, especially with larger sheets. Selecting a plotter with an appropriate maximum width streamlines your workflow and guarantees your workspace remains efficient.

Future Expansion Needs

Considering your future expansion plans is vital when selecting a plotter size, as upgrading later can be costly and disruptive. Choose a size that accommodates your anticipated growth to avoid frequent replacements. Think about how your workspace may evolve and whether your current plotter supports easy upgrades or additional features. Proper plotter maintenance is essential to ensure longevity, especially if you plan to scale up. Also, consider the availability of technical support for larger or more complex models, which can save you time and frustration down the line. Planning ahead helps you avoid bottlenecks and guarantees your equipment aligns with your long-term goals.

- Assess your projected workload to match plotter capacity

- Guarantee compatibility with future technical support needs

- Prioritize models with scalable features

- Maintain a focus on ease of plotter maintenance

How to Calculate the Total Cost of Ownership

Understanding the true cost of owning a plotter goes beyond its initial purchase price. To do this, you need to perform a thorough cost analysis that includes purchase costs, ongoing expenses, and potential downtime. Start by calculating the initial investment, then factor in maintenance planning—regular service, parts, and consumables like ink or toner. Don’t forget to consider energy consumption and potential repair costs over the machine’s lifespan. Reviewing these elements helps you identify hidden expenses and compare different models accurately. This extensive approach ensures you’re not just choosing based on sticker price but on the overall value. By understanding the total cost of ownership, you make smarter decisions that save money and improve your workflow long-term.

What User-Friendly Features Make a Plotter Easier to Use?

When choosing a plotter, user-friendly features can substantially streamline your workflow and reduce frustration. A well-designed user interface makes navigation intuitive, saving you time. A touch screen simplifies operation, allowing quick adjustments and easy access to settings. Features like customizable shortcuts and clear menus help prevent errors and improve efficiency. Additionally, an ergonomic layout ensures that common functions are within reach, minimizing unnecessary movements. These features empower you to operate the plotter confidently and smoothly, even if you’re new to the device. Prioritizing a user interface with a responsive touch screen and thoughtful design means you’ll spend less time troubleshooting and more on actual work. This focus on ease of use ultimately enhances productivity and makes your plotting tasks less stressful.

Which Connectivity Options Ensure Seamless Printing?

Seamless printing depends heavily on choosing the right connectivity options for your plotter. Wireless printing offers convenience, allowing you to send files from multiple devices without cables. Look for plotters with robust wireless capabilities, guaranteeing quick and reliable connections. Ethernet connectivity provides a stable, high-speed option ideal for office environments or large-volume printing. It ensures your plotter stays connected to your network without interruptions, especially when handling complex or large files. Combining wireless printing with Ethernet connectivity gives you flexibility and reliability, so you can print effortlessly from anywhere in your workspace. Prioritize these connectivity options to avoid delays, miscommunications, or connection failures that can hamper your productivity. The right setup makes your printing process smoother, faster, and more efficient.

What Additional Specs Impact Long-Term Plotter Performance?

Choosing the right connectivity options sets the foundation for reliable printing, but long-term performance depends on additional specifications that guarantee your plotter stays efficient over time. To assure durability and consistent output, consider features like high-quality build materials, reliable paper handling, and advanced maintenance tips. These specs help prevent breakdowns and extend your plotter’s lifespan. Also, pay attention to the brand reputation, as trusted brands often provide better support and durable components.

- Robust print engines resistant to wear

- Easy-access maintenance features

- Compatibility with future updates

- Proven reliability through positive user reviews

Focusing on these specs helps you avoid frequent repairs, keeps your investment protected, and maintains top performance over the years.

How to Balance Features and Budget When Buying a Plotter

Balancing features and budget is essential to getting a plotter that meets your needs without overspending. Focus on key specs like color accuracy, which affects the quality of your prints, especially for detailed or color-critical work. Don’t overlook ink compatibility, as choosing a model that supports affordable or readily available ink can save you money long-term. Prioritize features that directly impact your workflow, like print resolution and speed, while avoiding unnecessary extras that inflate costs. Set a clear budget but remain flexible on features that truly matter, so you don’t compromise quality for savings. Comparing models based on these priorities helps you find a plotter that offers the best value, ensuring you get the performance you need within your budget constraints.

Frequently Asked Questions

Can a Plotter’s Resolution Be Upgraded Later?

Think of a plotter’s resolution as a tailor-made suit—it’s built into the machine, and upgrading it later isn’t usually a simple fix. Most plotters don’t offer resolution upgrade possibilities because it involves hardware changes. If you need higher resolution, look for models with adjustable settings or plan to buy a new plotter. Always verify specifications before purchasing to make sure it meets your needs today and tomorrow.

How Does Ambient Temperature Affect Plotter Performance?

Ambient temperature directly impacts your plotter’s performance due to temperature sensitivity. If it’s too hot or cold, you might notice print quality issues or mechanical glitches. To avoid this, guarantee your workspace has proper climate control, maintaining a stable temperature. This helps your plotter operate smoothly, reduces errors, and prolongs its lifespan. Always keep the environment consistent, especially in extreme climates, to get the best results from your device.

Are There Eco-Friendly Plotter Options Available?

Like a gust of fresh air, eco-friendly plotter options are increasingly available. You can opt for models that prioritize sustainable printing, using energy-efficient technology and eco-conscious materials. These plotters reduce your environmental footprint while maintaining high performance. Investing in eco-friendly options not only supports sustainability but also helps you meet green business goals. Look for printers with ENERGY STAR certification and compatible biodegradable inks to make your printing process more eco-conscious.

What Is the Typical Lifespan of a Professional Plotter?

A professional plotter typically lasts between 5 to 10 years, depending on usage and maintenance. To prolong its lifespan, you should follow maintenance tips like regular cleaning, updating software compatibility, and replacing worn parts promptly. Proper care ensures your plotter runs smoothly, saving you money and hassle in the long run. Keep up with software updates and routine maintenance to get the most out of your investment.

How Important Is Brand Reputation When Choosing a Plotter?

You might think brand reputation isn’t vital, but it’s your secret weapon. Trust in a brand often comes from consistent quality and excellent customer reviews, giving you confidence in your choice. When you see a trusted name, you’re more likely to avoid surprises and costly repairs later. Don’t underestimate the power of reputation—it’s your first line of defense against buying a plotter that won’t meet your needs.

Conclusion

Choosing the right plotter is like finding the perfect partner—you want reliability, compatibility, and performance that lasts. By focusing on the specs that truly matter, you guarantee your investment pays off, avoiding costly mistakes. Don’t let features distract you from what’s essential; instead, let them guide your decision. Remember, a well-chosen plotter isn’t just a tool—it’s the heartbeat of your creative or professional projects, keeping your workflow smooth and your results superior.