Adhesive technologies for corrugated boards focus on ensuring strong, durable bonds while supporting sustainability goals. You’ll find eco-friendly formulations, such as water-based and bio-based adhesives, that reduce VOC emissions and use renewable materials. Cold glues offer benefits like easy application at room temperature, lower energy use, and compatibility with these eco-friendly options. If you keep exploring, you’ll discover how these advancements enhance packaging quality, efficiency, and environmental responsibility.

Key Takeaways

- Eco-friendly, water-based adhesives enhance sustainability and reduce VOC emissions in corrugated board production.

- Cold glue applications simplify handling, lower energy use, and enable bonding at ambient temperatures.

- Compatibility between eco-friendly formulations and cold adhesives ensures reliable, strong bonds without heat or solvents.

- Adhesive technologies improve manufacturing efficiency, product consistency, and support environmental compliance.

- Innovative adhesive systems contribute to safer workplaces and meet growing consumer demand for eco-conscious packaging.

Adhesive technologies play a crucial role in the production and performance of corrugated boards, ensuring they are strong, durable, and reliable for packaging applications. As someone involved in manufacturing or quality control, you understand the importance of selecting the right adhesives to meet both performance standards and environmental concerns. One key trend gaining momentum is the development of eco-friendly formulations. These adhesives are designed to reduce volatile organic compound (VOC) emissions and utilize renewable or biodegradable raw materials, aligning with sustainability goals. By opting for eco-friendly options, you contribute to a safer workplace and a healthier planet without compromising the integrity of the final product. These formulations often incorporate water-based or bio-based components that are less harmful and easier to dispose of, making them increasingly popular in modern manufacturing processes.

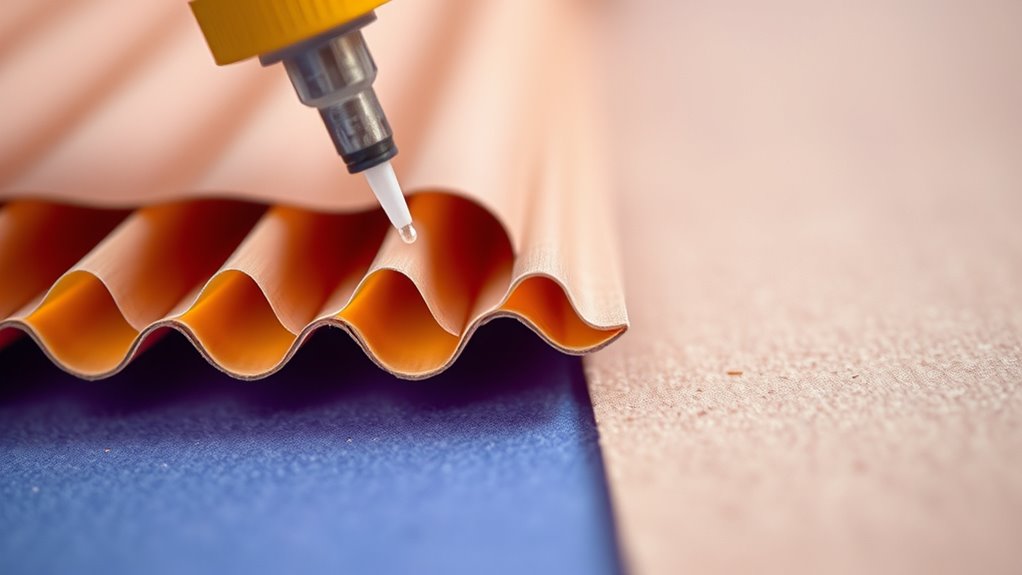

Cold glue applications are another critical aspect of adhesive technology in corrugated board production. Unlike hot melts or solvent-based adhesives, cold glues are applied at ambient temperatures, simplifying handling and reducing energy consumption. When you use cold glue applications, you benefit from faster setup times and easier application methods, which streamline your production line. Cold adhesives are particularly advantageous in situations where heat-sensitive materials are involved or when working with complex or delicate designs. Their versatility allows you to bond different layers of corrugated cardboard efficiently, ensuring a secure and stable structure. The ease of application also means less equipment complexity and maintenance, which can lower operational costs and reduce downtime.

Furthermore, the compatibility of cold glue with eco-friendly formulations is a significant advantage. Many eco-friendly adhesives are water-based, aligning perfectly with cold glue applications, since both can be applied at room temperature without the need for heat or solvents. This synergy simplifies the integration of sustainable adhesives into your existing production line, promoting greener manufacturing practices. You can achieve strong, reliable bonds while adhering to environmental regulations and customer demands for eco-conscious packaging solutions.

Frequently Asked Questions

How Do Adhesive Properties Affect Recyclability of Corrugated Boards?

Your choice of adhesive properties directly impacts the recyclability of corrugated boards. Strong adhesive bond strength guarantees the layers stay intact during use, but overly robust bonds can complicate recycling. Moisture resistance helps protect the board in humid environments, yet adhesives that resist moisture may hinder fiber separation during recycling. Ideally, you want adhesives that balance bond strength and ease of removal to promote efficient recycling processes.

What Are the Environmental Impacts of Different Adhesive Types?

Think of adhesives like a double-edged sword; some cut eco-friendliness, others protect recyclability. Biodegradable adhesives reduce landfill waste, but many traditional options emit toxic chemicals, harming air and water quality. For example, soy-based adhesives break down naturally, unlike solvent-based ones that release hazardous fumes. You should weigh these environmental impacts—biodegradability concerns versus toxic emissions—when choosing adhesives to minimize your ecological footprint and promote sustainable packaging.

How Does Temperature Influence Adhesive Performance During Storage?

You’ll notice that temperature substantially affects adhesive performance during storage. If temperatures aren’t stable, adhesives can lose their effectiveness due to poor temperature stability, leading to weaker bonds. Over time, adhesive aging accelerates in fluctuating temperatures, compromising their quality. To maintain ideal performance, store adhesives in a cool, consistent environment, which helps preserve their properties and extend their shelf life, ensuring reliable bonding when used.

Can Adhesives Be Customized for Specific Packaging Applications?

Yes, adhesives can be customized for specific packaging applications. You can develop custom adhesive formulations tailored to your unique needs, guaranteeing ideal bonding and performance. Application-specific adhesives are designed to meet particular requirements, such as temperature resistance, moisture tolerance, or flexibility. By working with suppliers to create these tailored solutions, you ensure your packaging performs reliably under various conditions, improving efficiency and product integrity.

What Are the Latest Innovations in Adhesive Technology for Corrugated Boards?

You’ll find that the latest innovations in adhesive technology for corrugated boards focus on eco-friendly adhesives and nanotechnology enhancements. These advancements help you reduce environmental impact while boosting performance. Eco-friendly adhesives, often derived from renewable sources, offer sustainable solutions, while nanotechnology improves bond strength and durability at a microscopic level. By embracing these innovations, you can create packaging that’s both eco-conscious and highly reliable, aligning with modern demands for sustainability and efficiency.

Conclusion

Now, picture the sturdy layers of corrugated boards seamlessly glued together, like a well-woven fabric of strength and resilience. With advanced adhesive technologies, you create a bond that holds together your packaging, no matter the journey. Every flap and fold comes alive with reliable adhesion, ensuring your products stay safe and secure. As you choose the right adhesive, you build a fortress of protection—strong, dependable, and ready to face any challenge ahead.