In 2025, expect biodegradable packaging films to feature advanced biopolymer blends, natural fillers, and multi-layer structures that boost strength and barrier performance. You’ll see innovations like eco-friendly coatings, smart sensors, and active additives that extend food shelf life while maintaining sustainability. Reinforced designs with natural fibers will enhance durability and flexibility. Ongoing improvements in production methods aim to cut costs and speed up adoption. Stay tuned to uncover how these emerging trends can transform your packaging solutions.

Key Takeaways

- Development of biodegradable polymer composites with natural fillers like cellulose and starch to enhance performance.

- Integration of nano-coatings and multi-layer structures for superior moisture and gas barrier properties.

- Utilization of natural extracts and botanical additives for antimicrobial and antioxidant functionalities.

- Advancement of smart packaging with biodegradable sensors for real-time monitoring of freshness and safety.

- Design of reinforced multi-layer films combining eco-friendly materials for improved durability and application scope.

Emerging Materials and Composition Breakthroughs

Recent advances in biodegradable packaging films have focused on developing innovative materials and compositions that enhance performance while reducing environmental impact. You now see a shift towards biopolymer blends, which combine different natural polymers to improve flexibility, strength, and processability. These blends enable manufacturers to tailor properties for specific applications, reducing reliance on synthetic plastics. Additionally, nanocomposite materials are gaining attention; by incorporating nanoscale fillers, you can markedly boost barrier properties and mechanical strength without sacrificing biodegradability. These emerging materials open new possibilities for sustainable packaging, allowing you to create films that are both eco-friendly and high-performing. As research progresses, expect these breakthroughs to become standard, helping reduce plastic waste and improve the overall sustainability of packaging solutions.

Enhancing Barrier Properties for Food Safety

You can improve food safety by adopting advanced coating technologies that create better barriers against moisture and gases. Incorporating natural additives into packaging films also helps enhance their protective properties without compromising biodegradability. Additionally, using multi-layer film structures allows you to combine materials for superior barrier performance. Emphasizing vetted formulations ensures the safety and effectiveness of new biodegradable films, and staying informed about industry standards can help guide the development of compliant and high-quality packaging solutions. Leveraging material innovation can further optimize barrier properties while maintaining environmental sustainability. Regularly testing pressure and adapting tire size based on terrain can also contribute to better performance and safety in various applications. Incorporating biodegradable polymers into film designs is essential for aligning with environmental goals and ensuring consumer acceptance.

Advanced Coating Technologies

How can advanced coating technologies improve the barrier properties of biodegradable packaging films to guarantee food safety? By applying innovative surface coatings, you can markedly reduce permeability to gases, moisture, and odors. These coatings, often developed with eco-friendly materials, enhance durability and food preservation. Printing techniques allow precise application of barrier layers, ensuring uniform coverage and excellent performance. Additionally, integration of Kia Tuning technologies such as ECU remapping and suspension upgrades demonstrates how precision application methods can be optimized for enhanced functionality and performance. Incorporating advanced manufacturing techniques further refines the coating process, leading to more consistent and effective barrier layers. The use of nano-coatings can significantly improve the impermeability of films, providing an extra layer of protection against environmental factors. Moreover, adopting biodegradable polymers derived from renewable sources can improve overall sustainability without compromising barrier effectiveness. Implementing natural techniques from organic farming methods can also contribute to the development of more sustainable and biodegradable materials for packaging. These advancements enable you to produce biodegradable films with superior barrier properties, meeting safety standards while maintaining sustainability.

Incorporation of Natural Additives

Incorporating natural additives into biodegradable packaging films offers an effective strategy to enhance their barrier properties and guarantee food safety. Natural extracts and botanical compounds can be integrated into the films to improve resistance against moisture, oxygen, and gases, which are critical for preserving freshness. These additives create a natural barrier that reduces the permeability of packaging materials, extending shelf life without relying on synthetic chemicals. Botanical compounds such as essential oils or plant-derived polyphenols possess antimicrobial and antioxidant properties, further protecting food from spoilage and contamination. By leveraging these natural ingredients, you can develop packaging solutions that are both eco-friendly and highly effective at maintaining food quality, aligning with consumer demand for safer, greener packaging options. Additionally, understanding the biodegradable material development process can help optimize the integration of these natural additives for maximum effectiveness. Recognizing the importance of barrier properties in packaging can guide the selection of suitable natural compounds to improve performance. Incorporating natural antimicrobial agents can also serve as a key factor in this enhancement process, providing an added layer of protection against microbial growth. Combining advanced formulation techniques with natural additives can further improve the functional properties of biodegradable films, making them more competitive with conventional plastics. Incorporating networking with industry experts can accelerate the development and adoption of innovative biodegradable solutions.

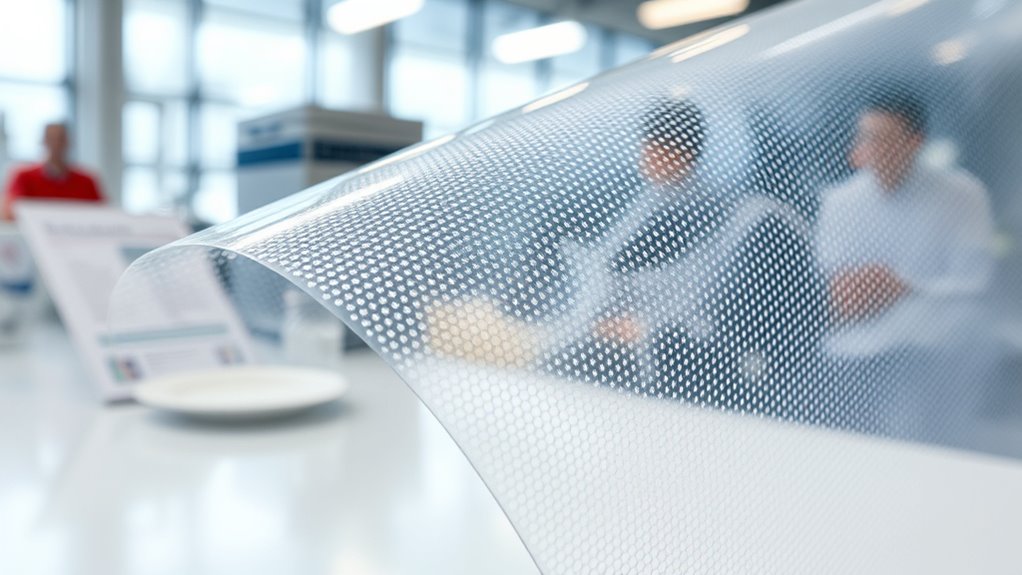

Multi-layer Film Structures

Building on the benefits of natural additives, designing multi-layer film structures offers a powerful approach to improve barrier properties and guarantee food safety. By combining different biodegradable materials, you create a layered barrier that effectively resists moisture, oxygen, and odors. This enhances sealing performance, ensuring the product stays fresh longer. Implementing layered barrier functions tailored to specific food types can further optimize protection. A compatibility analysis of materials ensures that each layer works harmoniously without compromising the overall integrity. Additionally, selecting materials with proven biodegradability ensures the entire packaging can break down efficiently in composting environments. Utilizing material compatibility in multilayer designs ensures the different layers work synergistically without compromising integrity. These multi-layer structures enable you to customize films for diverse applications, balancing biodegradability with essential barrier qualities. The layered barrier approach not only extends shelf life but also maintains product integrity, making it essential for future food packaging innovations. Incorporating sustainable design principles can further enhance the environmental benefits of biodegradable films.

Innovations in Flexibility and Mechanical Strength

Recent innovations focus on enhancing the flexibility and strength of biodegradable films through improved material compositions. Reinforced structural designs help these films withstand handling and packaging stresses effectively. Additionally, incorporating advanced cybersecurity measures in manufacturing processes can prevent disruptions and ensure product integrity. By combining these approaches, you can create packaging that’s both durable and adaptable to various applications. Regular testing and quality checks further ensure these films meet performance standards and durability requirements.

Enhanced Material Composition

Advancements in material composition have considerably boosted the flexibility and mechanical strength of biodegradable packaging films. You now benefit from improved formulations that incorporate innovative biodegradable polymers, enhancing durability without compromising eco friendliness. These materials often include blends that maximize strength and flexibility, making them suitable for various applications. Eco friendly coatings are also integrated to provide barrier properties and moisture resistance, reducing reliance on non-biodegradable additives.

- Use of biopolymer blends to tailor flexibility and strength

- Incorporation of natural fillers like cellulose or starch

- Development of biodegradable polymer composites

- Application of eco friendly coatings for enhanced barrier properties

- Fine-tuning polymer molecular structures for ideal performance

Reinforced Structural Design

Innovations in reinforced structural design are transforming biodegradable packaging films by considerably enhancing their flexibility and mechanical strength. Structural reinforcement techniques, such as incorporating natural fibers or nanomaterials, strengthen the film’s internal matrix, leading to improved durability. These advancements allow the films to withstand handling, transportation, and environmental stresses without tearing or deforming. Durability enhancement is achieved without sacrificing eco-friendliness, as sustainable materials are prioritized. By integrating reinforcement strategies, you can create packaging that’s lightweight yet resilient, meeting industry demands for both flexibility and strength. This progress not only extends the functional lifespan of biodegradable films but also broadens their application scope, ensuring they remain competitive against traditional plastics. Ultimately, reinforced structural design is key to advancing eco-friendly packaging solutions for 2025 and beyond.

Biodegradability Accelerators and Testing Standards

To effectively evaluate and enhance the biodegradability of packaging films, researchers rely on specific biodegradability accelerators and testing standards. Accelerators speed up degradation processes, helping you assess how quickly materials break down under various conditions. Testing standards ensure consistency, reliability, and comparability across studies. They specify parameters like temperature, humidity, and microbial activity. Key aspects include:

- Use of controlled composting environments

- Measurement of CO₂ evolution as a degradation indicator

- ISO and ASTM standards for biodegradability testing

- Simulated landfill and marine conditions

- Accelerated aging tests to predict long-term behavior

These tools help you verify whether your films meet environmental criteria and comply with regulations, ensuring your innovations are both effective and sustainable.

Incorporation of Biobased Additives and Fillers

Incorporating biobased additives and fillers into packaging films offers a sustainable way to enhance biodegradability while maintaining performance. By adding biobased additives, you can improve the mechanical properties and barrier functionalities of the films without compromising eco-friendliness. Natural fillers, such as cellulose, starch, or lignin, help reinforce the matrix, reduce material costs, and promote faster degradation once disposed of. These bio-based components are sourced from renewable resources, ensuring that the entire packaging remains environmentally friendly. You can tailor the formulation to achieve specific properties, like increased flexibility or strength, while still supporting biodegradability. Overall, integrating biobased additives and natural fillers aligns with sustainable packaging goals, making films more competitive and eco-conscious for 2025 and beyond.

Smart and Active Packaging Technologies

Building on the trend toward sustainable packaging, smart and active packaging technologies introduce functionalities that extend product shelf life and improve safety. You’ll find smart sensors that monitor temperature, humidity, and freshness in real-time, alerting you to potential spoilage. Active indicators change color or display signals when products are no longer safe to consume, providing immediate visual cues. These innovations help reduce waste and enhance consumer confidence. Key features include:

- Real-time freshness monitoring via smart sensors

- Visual active indicators for spoilage detection

- Incorporation of biodegradable sensing materials

- Integration with mobile apps for data tracking

- Improved safety through early warning systems

Scaling Up Production and Cost Reduction Strategies

Scaling up production of biodegradable packaging films presents both challenges and opportunities. You’ll face mass production challenges like maintaining quality consistency and optimizing manufacturing processes. To succeed, focus on cost efficiency strategies such as leveraging economies of scale, improving raw material sourcing, and streamlining operations. Investing in advanced equipment can reduce waste and energy use, lowering overall costs. Collaborating with suppliers and adopting automation helps increase output while keeping expenses in check. Additionally, developing standardized production protocols ensures uniformity and minimizes defects. By addressing these challenges head-on and implementing effective cost strategies, you can make large-scale production more viable and affordable. This not only enhances your competitive edge but also accelerates the adoption of biodegradable films across industries, supporting sustainability goals.

Regulatory Developments and Industry Adoption Trends

Recent regulatory developments are shaping how biodegradable packaging films are adopted across industries. Governments and organizations are tightening regulations around regulatory compliance and industry standards to promote sustainability. You’ll notice stricter labeling requirements, eco-friendly certifications, and bans on single-use plastics. These changes encourage manufacturers to innovate and meet new standards swiftly. To stay ahead, you should focus on:

- Ensuring materials meet evolving industry standards

- Obtaining relevant eco-label certifications

- Monitoring legislative updates for compliance

- Incorporating sustainable practices into production

- Engaging with policymakers to influence future regulations

These shifts drive industry-wide adoption of biodegradable films, making regulatory compliance essential for market success. Staying informed and adaptable is key to steering this evolving landscape effectively.

Frequently Asked Questions

What Are the Environmental Impacts of Biodegradable Packaging Films After Disposal?

You might wonder about the environmental impacts of biodegradable packaging films after disposal. These films generally break down faster, reducing marine pollution and soil contamination. However, if they don’t decompose properly, they can still contribute to pollution or harm ecosystems. Proper disposal and composting are essential to guarantee they truly benefit the environment, helping prevent issues like marine pollution and soil contamination caused by conventional plastics.

How Do Consumer Preferences Influence Biodegradable Packaging Innovations?

Like the whisper of the wind shaping the landscape, consumer preferences mold packaging innovations. Your acceptance and demand drive companies to prioritize eco-friendly solutions, aligning with market trends favoring sustainability. When you choose biodegradable packaging, you influence industry shifts, encouraging brands to develop films that meet your values. Your choices act as catalysts, inspiring continuous innovation toward environmentally responsible options for 2025 and beyond.

Are There Any Potential Health Risks From New Biodegradable Additives?

You might wonder if new biodegradable additives pose health risks. While synthetic additives are used to enhance film properties, they can sometimes trigger allergic reactions in sensitive individuals. Manufacturers are actively researching safer, natural alternatives to minimize these risks. As a consumer, it’s wise to stay informed about ingredient disclosures and choose products with transparent labeling to reduce exposure to potential allergens and guarantee safer packaging options.

How Do Biodegradation Rates Vary in Different Climatic Conditions?

You’ll notice that climatic effects considerably influence biodegradation rates, causing degradation variability across different environments. In warm, humid conditions, biodegradable films tend to break down faster due to increased microbial activity. Conversely, in colder or drier climates, degradation slows down, extending the lifespan of packaging. Understanding these climatic effects helps you select suitable materials for specific regions, ensuring ideal performance and eco-friendliness regardless of environmental variations.

What Are the Long-Term Durability Considerations for Biodegradable Films?

Think of biodegradable films as delicate dancers—graceful but needing proper support. You must consider long-term durability to guarantee film integrity and shelf stability over time. Factors like moisture, temperature, and microbial activity can weaken the films, causing them to break down prematurely. To keep them performing well, choose materials with balanced biodegradability and strength, ensuring your packaging remains reliable until it’s time for disposal.

Conclusion

As you explore innovations in biodegradable packaging for 2025, remember that you’re shaping a future where sustainability is as natural as riding a horse to the moon. With breakthroughs in materials, enhanced barrier properties, and smart tech, you can help reduce plastic waste and protect the planet. Embrace these advancements like a modern-day inventor, and watch how your choices lead to a greener, more responsible world—no flux capacitor required.