Flexographic printing is ideal if you need high-volume output with vibrant colors and substrate versatility but requires higher initial setup costs. Digital printing offers quick turnaround, lower setup expenses, and excellent customization for short runs and detailed designs. Consider flexo for consistent, large-scale packaging or digital for flexibility and personalization. To discover which method best fits your project’s specific needs, explore more about their differences and advantages.

Key Takeaways

- Flexographic printing offers high-volume efficiency with lower variable costs, while digital provides flexibility with lower setup costs for short runs.

- Flexo excels in vibrant, consistent colors and printing on diverse substrates, whereas digital supports detailed designs and personalization.

- Digital printing delivers faster turnaround and minimal setup times, ideal for quick, small-batch packaging; flexo is better for large-scale, uniform production.

- Flexo involves higher initial setup but lower per-unit costs over time; digital reduces waste and is more environmentally friendly for short runs.

- Both methods are advancing technologically, with flexo aligning with eco-friendly materials and digital enhancing customization and rapid production.

Overview of Flexographic Printing

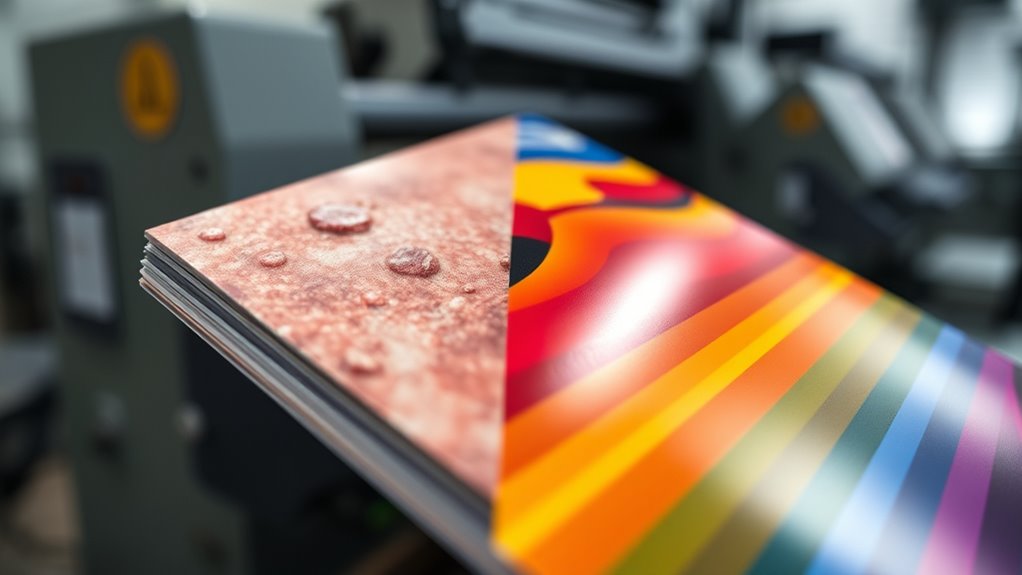

Flexographic printing, often called flexo, is a versatile and efficient printing method widely used for packaging and labels. Its flexographic advantages include fast turnaround times, cost-effectiveness for large runs, and the ability to print on a variety of substrates, such as plastics, foil, and paper. This makes it ideal for producing high-quality labels, bags, and cartons. Flexo’s printing innovation lies in its use of flexible relief plates, which allow for quick plate changes and reduced setup times. The method’s ability to produce vibrant colors and sharp images at high speeds benefits manufacturers looking for consistent, high-volume production. Overall, flexographic printing remains a popular choice because it combines efficiency, adaptability, and quality to meet the demands of modern packaging needs. Additionally, the method’s compatibility with natural materials aligns well with the eco-friendly trends in packaging. The versatility of flexo also allows for printing on multiple substrates, making it highly adaptable for various packaging applications. This adaptability is further enhanced by ongoing advancements in printing technology, ensuring that flexographic printing continues to meet evolving industry standards.

Overview of Digital Printing

Digital printing has revolutionized the printing industry by offering a highly flexible and efficient alternative to traditional methods. It allows for quick turnaround times and precise digital customization, making it ideal for short runs and personalized packaging. Inkjet technology, a key component, showcases remarkable versatility by printing on various substrates, including plastics and foils. This flexibility means you can produce complex designs with vibrant colors and sharp details without extensive setup. Additionally, digital printing supports personalized learning pathways through customizable outputs, enhancing the ability to meet specific customer needs. Here’s a quick comparison:

| Feature | Benefit |

|---|---|

| Digital customization | Personalize each package easily |

| Inkjet versatility | Prints on diverse materials |

| Fast production | Shorter lead times |

| Cost-efficient for small runs | Reduces waste and setup costs |

| High-quality output | Sharp images and consistent colors |

Cost Analysis and Economic Considerations

When comparing flexographic and digital printing, you’ll notice significant differences in production costs, especially for large runs. Digital may have higher per-unit expenses initially, but flexographic often offers lower costs over time with high-volume orders. Considering your long-term investment, it’s essential to evaluate which method aligns best with your production scale and budget. Additionally, understanding wall organization systems can help in designing packaging that enhances visual appeal and functionality. Recognizing the cost efficiency of each method allows for better planning and resource allocation in your packaging projects. For example, knowing how different printing techniques impact overall expenses can aid in making more informed decisions. Moreover, choosing the right printing method can influence the durability and quality of the final product, affecting customer perception and brand value. Incorporating material durability considerations can further optimize your packaging investments to ensure longevity and customer satisfaction.

Production Cost Differences

Understanding the production costs of each printing method is essential for making informed decisions about your printing projects. Flexographic printing typically involves higher initial setup costs due to plate creation, but its variable costs decrease with larger runs. Digital printing, on the other hand, has lower setup costs and is more cost-effective for short runs. When comparing variable costs, digital printing often reduces material wastage because it prints directly onto substrates without the need for extensive plates or setup. Flexography may generate more waste during plate preparation and make-ready, increasing overall costs for small quantities. Additionally, application timing can influence the efficiency and waste reduction in the printing process. Ultimately, your choice depends on the project size and frequency. Carefully analyzing these cost differences helps you optimize budgets and select the most economical printing method for your needs.

Long-term Investment Impact

Evaluating the long-term investment impact of flexographic and digital printing requires careful analysis of both initial costs and ongoing expenses. Flexographic presses often demand higher upfront investments but can offer lower per-unit costs over high-volume runs, boosting your ability to build brand loyalty through consistent, quality packaging. Digital printing, while initially more affordable, incurs higher costs with increased production volume, potentially limiting long-term profitability. However, its market adaptability allows you to quickly respond to changing consumer trends and customize short runs, strengthening your brand’s relevance. Consider how each method aligns with your business goals—whether prioritizing cost efficiency for large-scale production or flexibility for dynamic, personalized packaging. This balance influences your overall return on investment and market positioning over time. Additionally, understanding the cost analysis of each method can help optimize your purchasing decisions and strategic planning. Incorporating energy efficiency considerations can further reduce operational costs and enhance sustainability. Evaluating production scalability is crucial when selecting a printing method to ensure it can meet future growth demands efficiently. Moreover, analyzing long-term maintenance costs can reveal hidden expenses that impact overall profitability. Furthermore, understanding the cultural and brand impact of each printing method can help align your packaging with your marketing strategy and consumer engagement goals.

Quality and Design Capabilities

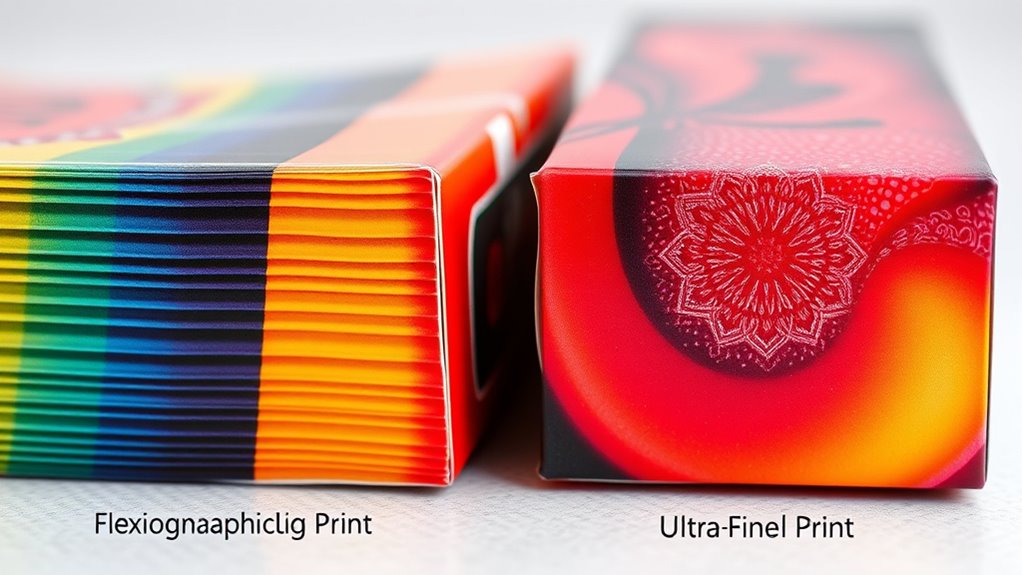

Both flexographic and digital printing offer impressive quality and design capabilities, but they excel in different areas. Flexographic printing provides excellent color accuracy, especially with spot colors and Pantone matching, ensuring vibrant, consistent results. It also offers high material versatility, allowing you to print on a wide range of substrates like plastics, foils, and corrugated materials. Additionally, material versatility enables printing on unconventional packaging surfaces. Digital printing, on the other hand, shines in producing detailed images and complex designs with sharp resolution. It’s ideal for short runs or customized labels, where intricate graphics matter. While flexography is better for large-volume, uniform designs with consistent color, digital excels in quick turnaround and personalized options. Your choice depends on your project’s specific needs for color precision and material compatibility. Additionally, sound design techniques such as digital sound synthesis can influence the overall cost-effectiveness of your printing projects depending on your location. Moreover, understanding the operating hours of local print providers can help in planning your production timeline effectively.

Production Speed and Turnaround Times

When comparing flexographic and digital printing, you’ll notice differences in how quickly each process produces finished products. Setup times can vary markedly, affecting your overall turnaround, especially for smaller or custom orders. Understanding these speed and efficiency factors helps you choose the right method for your production schedule. Additionally, jet propulsion technology can influence the speed capabilities of certain printing equipment, contributing to faster production times. For example, some modern printing presses incorporate advanced automation, which can significantly reduce manual intervention and further expedite the process.

Printing Speed Differences

Have you ever wondered which printing method can deliver your projects faster? When it comes to production speed, digital printing often offers higher throughput, especially for short runs, because it skips many traditional setup stages. This allows you to meet tight deadlines more effectively. Flexographic printing, however, can achieve rapid production once the initial setup is complete, making it suitable for large-volume jobs. Workflow automation also plays a significant role—digital presses typically integrate seamlessly with automated systems, reducing manual intervention and speeding up turnaround times. Overall, digital printing tends to provide faster turnaround for smaller batches, while flexography’s speed benefits are more apparent in high-volume, continuous production. Your choice depends on your project size and required speed.

Setup Time Variations

Setup times considerably influence production speed and turnaround times in printing. The setup time, including changeover duration, determines how quickly you can switch between jobs, impacting overall efficiency. Flexographic printing often requires longer setup times due to cylinder preparation and ink adjustments, which can delay start-up. Conversely, digital printing minimizes setup time, allowing for rapid changeovers and shorter turnaround times. Key factors affecting setup time include:

- Complexity of the design – intricate designs take longer to prepare.

- Type of printing technology – flexographic needs more extensive changeovers.

- Material changeovers – switching substrates adds to setup duration.

Understanding these factors helps you optimize your workflow, reducing delays and improving overall productivity.

Production Efficiency Levels

Production efficiency levels, including printing speed and turnaround times, directly impact your ability to meet deadlines and fulfill customer demands. Faster production means quicker delivery and higher label durability, especially when consistent color quality is maintained. Flexographic printing typically offers higher speeds for large runs, but digital printing excels in rapid turnaround and short runs. Consider the table below:

| Aspect | Flexographic Printing | Digital Printing |

|---|---|---|

| Production Speed | High for large quantities | Faster for short runs |

| Turnaround Times | Longer setup, slower | Quick setup, rapid output |

| Color Consistency | Excellent with proper calibration | Slightly variable, but improving |

Choosing the right method depends on balancing speed with the need for consistent color and durable labels.

Environmental Impact and Sustainability

While both flexographic and digital printing methods aim to meet industry demands, their environmental impacts differ considerably. Flexographic printing often uses solvent-based inks, which can release VOCs, whereas digital printing typically employs eco friendly inks that reduce emissions. You’ll find that digital printing offers better recycling opportunities due to less waste and simpler cleanup processes. Additionally, digital methods generally consume less energy for small runs, lowering your carbon footprint. Flexographic printing, however, can be more sustainable at large volumes when using biodegradable inks and optimizing ink usage. Overall, digital printing’s lower waste generation and eco friendly ink options make it more environmentally friendly, but flexographic’s potential for sustainability depends on adopting greener inks and practices.

Ideal Applications and Industry Use Cases

Choosing between flexographic and digital printing depends largely on your specific industry needs and project requirements. Flexographic printing excels in high-volume applications like labels, cartons, and flexible packaging, thanks to its cost-effectiveness and fast turnaround. It offers strong brand versatility with vibrant, consistent colors suitable for long runs. Digital printing, on the other hand, shines in short runs and customized projects, making it ideal for seasonal adaptations and limited editions. It allows for quick changes and personalized designs without the need for costly plates. If your focus is on large-scale production with high quality and brand consistency, flexography is your best choice. For small batches, rapid turnaround, and frequent updates, digital printing provides the flexibility and agility you need.

Frequently Asked Questions

Which Printing Method Offers Better Color Consistency for Branding?

You want to know which printing method offers better color consistency for branding. Generally, digital printing provides superior color accuracy due to better ink stability and precise color matching. It allows you to reproduce consistent colors across multiple prints, ensuring your branding remains sharp and uniform. Flexographic printing, while efficient for large runs, might struggle with color accuracy and ink stability, leading to slight variations over time.

How Do Maintenance Requirements Compare Between Flexographic and Digital Presses?

Think of press maintenance like tuning a car; regular care keeps everything running smoothly. With flexographic presses, you’ll face more frequent cleaning, leading to increased press downtime. Digital presses typically require less maintenance, so you spend less time on cleaning and more on production. Your choice affects how often you stop printing for maintenance, impacting overall efficiency. Keep in mind, less downtime means quicker turnaround and happier clients.

Can Both Methods Print on Biodegradable or Eco-Friendly Packaging Materials?

You can definitely print on eco-friendly substrates using both methods. Digital printing easily handles biodegradable inks and materials, making it perfect for small runs and quick changes. Flexographic presses also print well on eco-friendly substrates, especially with specialized inks. Both methods support sustainable packaging, but digital offers more flexibility for eco-conscious designs and quick turnaround times, helping you meet your environmental goals efficiently.

What Are the Limitations of Each Technique for Small Batch or Custom Jobs?

When it comes to small batch or custom jobs, you’re often caught between a rock and a hard place. Flexographic printing struggles with batch flexibility and tends to have higher cost implications for short runs, making it less ideal. Digital printing, while more adaptable, can be limited by its color range and material compatibility. Both techniques might not be the best fit for highly specialized, low-volume projects.

How Do Post-Printing Processes Differ Between Flexographic and Digital Printing?

You’ll notice that post-printing processes differ between flexographic and digital printing. With flexographic, ink drying takes longer, often requiring curing or drying steps. You might also use embossing techniques to add texture after printing. Digital printing, on the other hand, generally dries faster, allowing for quicker finishing. This makes digital ideal for short runs where rapid turnaround and detailed embossing are desired.

Conclusion

So, whether you’re dreaming of eco-friendly prints or racing against the clock, remember: flexographic’s like a trusty old truck—reliable and cost-effective—while digital’s a sleek sports car, ready to impress with speed and detail. Pick your ride wisely, because in the world of packaging, your choice determines if you’re cruising smoothly or stuck in traffic. Just don’t forget, in this race, quality and sustainability are the pit stops that truly matter.