Custom cardboard engineering lets you create packaging that’s both innovative and visually striking. By combining advanced die-cutting, creasing techniques, and eco-friendly materials, you can design unique shapes and graphics that stand out on shelves. These designs not only enhance your brand’s identity but also improve functionality with clever features and user-friendly details. To discover how these creative solutions can transform your packaging, keep exploring the latest trends and techniques.

Key Takeaways

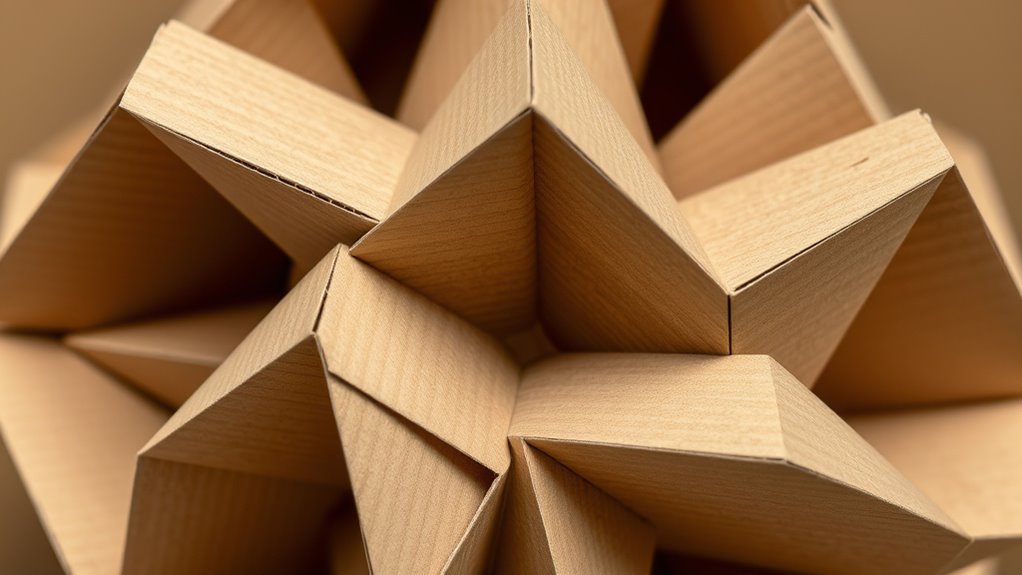

- Utilize advanced folding patterns like concertina and accordion to create innovative, eye-catching packaging shapes.

- Incorporate precision cutting and creasing technologies for intricate, custom design features.

- Select eco-friendly, biodegradable materials and adhesives for sustainable, unique packaging solutions.

- Integrate branding elements through vibrant graphics, custom shapes, and tactile textures for memorable packaging.

- Apply innovative structural reinforcement techniques to ensure durability of complex, custom-designed packages.

Exploring the Art of Structural Design in Cardboard Packaging

Have you ever wondered how cardboard packaging manages to be both lightweight and incredibly sturdy? It all comes down to smart structural design, especially the use of folding patterns. These patterns are carefully engineered to optimize strength while minimizing material use. By strategically folding the cardboard, you create reinforced edges and layers that enhance the packaging’s structural integrity. Proper folding not only guarantees durability during transportation but also improves overall performance under stress. When designing packaging, attention to structural design allows you to distribute weight evenly and resist crushing or bending. This precise engineering transforms simple sheets of cardboard into robust containers, balancing lightweight convenience with the strength needed to protect valuable contents. The use of zoning laws and secure storage solutions further ensures the integrity of the packaging over time, reflecting the importance of considering all aspects of structural design. Additionally, leveraging sound design principles can help optimize the functionality and resilience of packaging structures. It’s a blend of art and science that’s vital for effective packaging solutions.

Innovative Techniques for Custom Die Cutting and Creasing

You can achieve perfect cuts and folds by leveraging precision cutting technologies that guarantee accuracy every time. Custom creasing techniques allow you to create complex designs that enhance both functionality and aesthetics. Understanding material compatibility is key to selecting the right methods and tools for your specific cardboard projects. Additionally, incorporating color accuracy considerations can help ensure your packaging visuals are vibrant and true to your brand identity. Being aware of support hours for various services can also assist in planning your project timelines effectively. Incorporating knowledge of sound healing science can inspire designs that evoke a sense of well-being and harmony in your packaging concepts. Moreover, selecting appropriate creasing techniques can significantly improve the durability and appearance of your finished packaging.

Precision Cutting Technologies

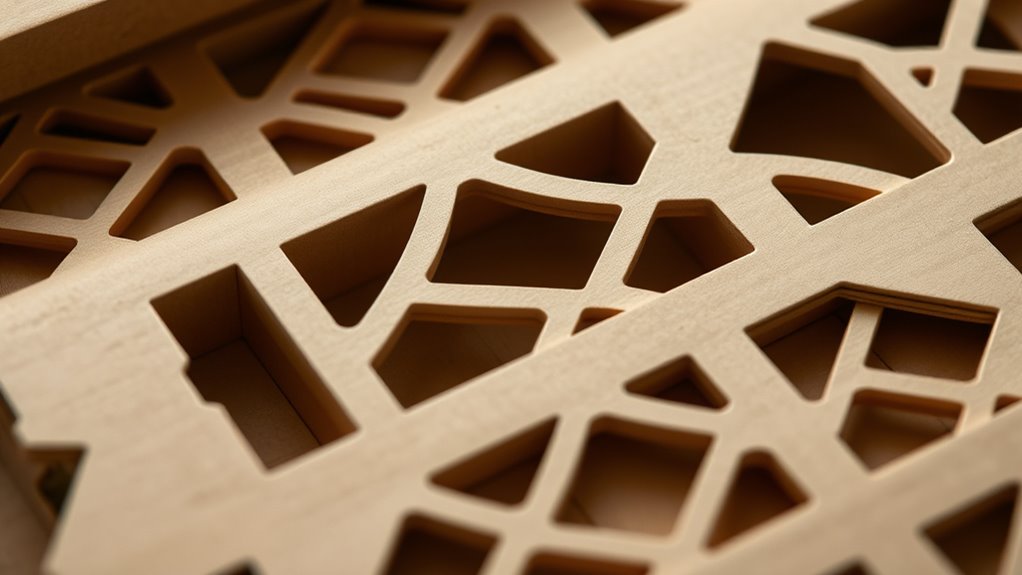

How can advanced cutting techniques redefine the precision and flexibility of custom cardboard designs? Laser precision allows you to achieve intricate, detailed cuts that are impossible with traditional methods, ensuring your packaging looks sharp and professional. Automated manufacturing systems enhance consistency, reducing errors and speeding up production. These technologies enable you to create complex shapes and patterns with tight tolerances, giving your packaging a unique edge. You can easily customize designs without sacrificing accuracy, making your products stand out on shelves. Laser cutting’s clean edges minimize waste and post-processing, streamlining your workflow. Additionally, adjustable settings allow for fine-tuning the process to accommodate various materials and design complexities. Incorporating meditation techniques into your workflow can also improve focus and precision during the design process, leading to even better results.

Custom Creasing Techniques

Innovative creasing techniques are transforming the way custom die-cutting enhances packaging design by delivering cleaner, more precise folds. These methods allow you to develop complex folding patterns that improve overall aesthetics and functionality. By focusing on crease reinforcement, you guarantee durability, preventing cracks or tears over time. Advanced tools enable you to create sharp, consistent creases that facilitate smooth folding, even in intricate designs. Here’s a comparison of folding pattern types:

| Folding Pattern | Benefits |

|---|---|

| Straight Folds | Simple, quick, cost-effective |

| Concertina Folds | Adds flexibility and volume |

| Mountain/Valley | Creates dimensional effects |

| Accordion Folds | Enhances structural integrity |

Mastering these techniques helps produce packaging that’s both visually striking and structurally sound. Additionally, understanding folding pattern features can lead to more innovative and practical packaging solutions, especially when considering bank and finance standards for quality and reliability. Incorporating industry standards into your design process ensures that your packaging meets the stringent requirements of various sectors, providing added credibility and customer trust. Moreover, leveraging Gold IRA principles can inspire secure and valuable packaging concepts that emphasize durability and trustworthiness. Staying informed about latest industry innovations can further enhance your design capabilities and keep you ahead in the competitive packaging market.

Material Compatibility Insights

Building on advanced creasing techniques, understanding material compatibility is key to achieving ideal results in custom die cutting and creasing. Not all cardboard types respond the same way, so you need to consider thickness, fiber composition, and coating when selecting materials. Proper material compatibility ensures clean cuts and sharp creases without tearing or cracking. Additionally, adhesive selection plays a crucial role; some adhesives may cause distortion or weaken the material during the process. Choosing the right adhesive ensures secure bonding without compromising structural integrity. Testing different materials and adhesives beforehand helps identify optimal combinations, reducing waste and rework. Considering the material response of different cardboard types can significantly improve the quality of your finished product. Incorporating industry standards can further guide material selection and process optimization. By paying attention to material compatibility, you’ll enhance the precision, durability, and overall quality of your custom packaging designs.

Incorporating Eco-Friendly Materials for Sustainable Packaging

Incorporating eco-friendly materials into packaging not only reduces environmental impact but also appeals to consumers seeking sustainable options. By using biodegradable materials and recycled content, you demonstrate your commitment to sustainability while reducing waste. These materials break down naturally or are repurposed, minimizing landfill contributions. Embracing the vibrational alignment with eco-conscious values can further enhance your brand’s resonance with environmentally aware customers. Utilizing innovative recyclable packaging options can also set your brand apart in a competitive market. Additionally, selecting materials that are biodegradable ensures your packaging decomposes efficiently, reducing long-term environmental footprint. Incorporating sustainable materials helps meet increasing regulatory standards and consumer expectations for eco-friendly practices.

Consider how this impacts your audience:

| Emotional Benefit | Practical Impact |

|---|---|

| Confidence in your brand | Less environmental guilt |

| Pride in sustainability | Cost savings over time |

| Trust from eco-conscious consumers | Positive brand image |

Choosing eco-friendly options shows you care, building trust and loyalty. It’s a small change with a big impact—both for the planet and your business success.

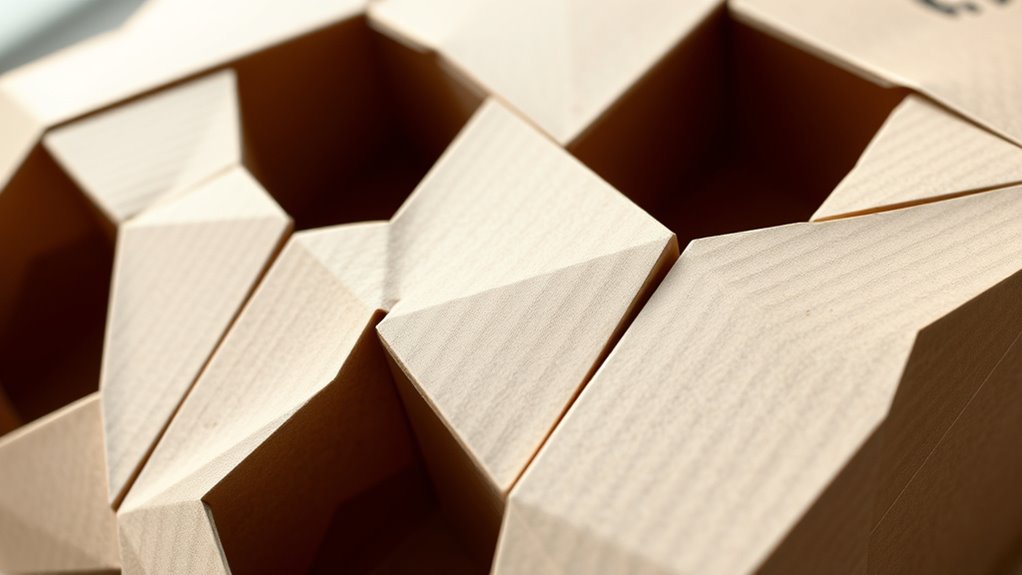

Enhancing Brand Identity With Unique Packaging Shapes and Graphics

To truly stand out on crowded shelves, leveraging unique packaging shapes and eye-catching graphics can considerably strengthen your brand identity. When you choose distinctive forms, you create a memorable tactile experience that reinforces your brand storytelling. Incorporating creative graphics and bold visuals enhances your visual branding, making your product instantly recognizable. Eye-catching shapes can evoke emotions or associations related to your brand, helping customers connect with your story. Consistent use of colors, logos, and design elements across your packaging builds a cohesive brand image. This visual branding not only attracts attention but also communicates your values and personality. Ultimately, innovative packaging shapes combined with compelling graphics make your product memorable, fostering brand loyalty and differentiation in a competitive marketplace.

Combining Functionality and Aesthetics for User-Friendly Designs

While striking visuals and unique shapes grab attention, guaranteeing your packaging is also highly functional enhances the overall user experience. Incorporating ergonomic design elements makes handling easier and more comfortable. To achieve this, focus on:

- Ease of opening and closing – simple tabs or tear strips prevent frustration.

- Secure product placement – custom inserts or compartments protect items and improve usability.

- Intuitive design – clear labels and minimal effort to access contents streamline the experience.

Balancing aesthetics with practicality creates a packaging that not only looks appealing but also serves its purpose efficiently. When your design considers ergonomic factors, it fosters a positive user experience, encouraging repeat engagement. Combining these elements ensures your custom cardboard packaging stands out while delivering functionality.

Future Trends in Custom Cardboard Engineering and Packaging Solutions

Future trends in custom cardboard engineering focus on eco-friendly innovations that reduce environmental impact and enhance sustainability. You’ll also see more smart packaging solutions that incorporate technology to improve user experience and tracking. These advancements are shaping a more efficient and responsible packaging industry for the years ahead.

Eco-Friendly Innovations

Are eco-friendly innovations shaping the future of custom cardboard engineering? Absolutely. You’re seeing a shift toward sustainable solutions that reduce environmental impact. Here are three key trends:

- The use of recyclable adhesives, which guarantee packaging can be easily disassembled and reused or recycled.

- Incorporating biodegradable inks, so printing doesn’t contribute to pollution or landfill waste.

- Designing for minimal material use without sacrificing strength or durability, lowering waste overall.

These innovations enable you to create packaging that’s both functional and eco-conscious. By embracing recyclable adhesives and biodegradable inks, you support sustainability goals and appeal to environmentally aware consumers. As these trends grow, your ability to adapt will set your packaging apart in a competitive market.

Smart Packaging Integration

Have you considered how smart packaging is transforming custom cardboard solutions? By integrating smart sensors, you can monitor temperature, humidity, and shock during transit, ensuring product integrity. RFID integration allows for real-time tracking and seamless inventory management, reducing losses and improving supply chain efficiency. These technologies enable you to create interactive packaging that communicates with consumers and logistics providers alike. Smart packaging not only enhances security but also offers valuable data insights, helping you optimize packaging designs and distribution strategies. As future trends, expect more sophisticated sensors and RFID systems to become standard features. Embracing these innovations positions your packaging solutions at the forefront of customization, delivering smarter, more connected experiences for your customers and supply chain partners.

Frequently Asked Questions

How Do Custom Cardboard Designs Improve Product Protection?

Custom cardboard designs improve product protection by offering tailored solutions that fit your items perfectly. Using sustainable materials, you reduce environmental impact while ensuring durability. Innovative folding techniques strengthen the packaging, providing extra cushioning and support. This precise fit minimizes movement during transit, preventing damage. Ultimately, these custom designs enhance your product’s safety, showcase your brand’s commitment to sustainability, and create a memorable unboxing experience for your customers.

What Are Cost Considerations for Custom Packaging Projects?

They say “money doesn’t grow on trees,” and that’s especially true for packaging projects. When you do a cost analysis and budget planning, you can identify expenses like materials, design, and production. Custom packaging might cost more upfront but offers better protection and branding. Balancing quality and cost helps you make smart choices, ensuring your project stays within budget while meeting your product’s needs.

Can Bespoke Cardboard Structures Be Easily Mass-Produced?

You might wonder if bespoke cardboard structures can be easily mass-produced. With advancements in manufacturing, it’s possible to produce these custom designs efficiently, especially when using sustainable materials. The key is leveraging design flexibility to streamline production processes, reducing costs and time. While some intricate structures may require specialized equipment, many custom cardboard solutions can be scaled up effectively, making mass production feasible without sacrificing quality or sustainability.

How Does Custom Packaging Influence Consumer Purchasing Decisions?

When you choose custom packaging, you enhance your product’s visual appeal, making it more attractive and memorable. This can boost brand loyalty, as consumers associate the unique design with quality and care. Eye-catching packaging draws attention on shelves, encouraging purchases. Ultimately, your custom packaging influences buying decisions by creating a strong first impression, fostering trust, and differentiating your product from competitors.

What Are the Best Practices for Designing User-Friendly Packaging?

When designing user-friendly packaging, focus on ergonomic handling to make opening and carrying easy for consumers. Incorporate clear visual branding to instantly communicate your product’s identity and attract attention. Use intuitive layouts and simple instructions to enhance usability. Choose durable materials that withstand handling. Prioritize functionality alongside aesthetics, ensuring your packaging feels welcoming and practical. This approach boosts customer satisfaction and encourages repeat purchases.

Conclusion

By embracing innovative structural designs and eco-friendly materials, you can create packaging that truly stands out. Imagine designing a custom box that not only protects your product but also enhances your brand’s story—like a cosmetics company using unique shapes and graphics to turn packaging into a marketing tool. Stay ahead by exploring future trends, blending functionality with eye-catching aesthetics. Your next packaging project could be the one that leaves a lasting impression and drives your brand’s success.